You can order custom turning of aluminum parts online very quickly. Just upload your CAD file and pick your options. You will get a price right away from a trusted supplier like AFI Industrial Co., Ltd. You can check your order and handle delivery with simple online tools. Make sure your files work and pick a good partner. This helps you have a smooth time when turning of aluminum parts.

Tip: Good CAD files help you get the best results fast.

Key Takeaways

- Ordering custom aluminum parts online is fast. You just upload your CAD file. You get a quote right away.

- Pick a supplier with good reviews. Find companies that do CNC machining.

- Make sure your design files are ready. Use the right CAD formats. This stops delays.

- Add clear technical drawings. These show what you need.

- Pick the best aluminum grade for your job. Each grade changes strength and how easy it is to machine.

- Look at shipping choices and delivery times. Fast shipping helps you finish on time.

- Check your order before you confirm it. Make sure sizes, materials, and instructions are right.

- Save your order history. This helps you next time and keeps things the same.

Table of Contents

Find a Supplier for Custom Metal Parts

The first thing to do is pick the right online metal fabricator. You need a supplier who knows cnc machining and understands your project. A good supplier makes things easy and sends you high-quality custom metal parts on time.

Research Online Machining Services

Begin by looking for online metal fabricators that do cnc machining for aluminum parts. Try to find companies with advanced machines, like 3, 4, and 5-axis cnc machines. These machines help you order custom metal parts that are complex and need tight tolerances.

Some top online metal fabricators are AFI Industrial Co., Ltd, Geomiq, and Hubs. These suppliers give instant quotes and help with custom projects. AFI Industrial Co., Ltd is known for great service and skill in cnc machining. Geomiq and Hubs also give fast quotes and quick production for custom metal parts.

Tip: Choose an online metal fabricator with a good reputation for quality and fast work.

Compare Ratings and Reviews

Check ratings and reviews before you pick an online metal fabricator. Customer feedback shows how well a supplier handles custom metal parts and cnc machining orders. Look for comments about quality, delivery speed, and customer support.

A supplier with ISO 9001 certification and first article inspection cares about quality. You want a company that answers questions fast and fixes problems. Good support makes ordering custom metal parts online much easier.

Check Service Features

When you compare online metal fabricators, look at features that matter for custom metal parts:

- Instant Quotes: Upload your design and get a price right away.

- Free Shipping: Some suppliers ship custom metal parts for free in the US.

- Expedited Production: Fast work helps you meet tight deadlines.

- Scalability: The supplier should handle both small and big orders.

- Transparent Pricing: Clear prices mean no hidden fees.

| Supplier | Instant Quote | Free Shipping | Expedited Production | CNC Capabilities |

|---|---|---|---|---|

| AFI Industrial Co., Ltd | ✅ | ✅ | ✅ | 3, 4, 5-axis |

| Geomiq | ✅ | ✅ | ✅ | 3, 4, 5-axis |

| Hubs | ✅ | ❌ | ✅ | 3, 4, 5-axis |

Pick an online metal fabricator that fits your needs for custom metal parts. Instant quotes, free shipping, and fast production make ordering cnc machined aluminum parts simple and quick.

Prepare Your Custom Design Files

Getting your design files ready is very important. You need to do this before you order custom aluminum parts online. Make sure your files work with the supplier’s system. Your files should have all the details needed for a correct quote and making the part. AFI Industrial Co., Ltd and other top suppliers use advanced systems. These systems can open many file types if you give clear information.

CAD File Formats (STP, STEP, SLDPRT)

You should save your CAD files in formats that online machining services accept. Most suppliers, like AFI Industrial Co., Ltd, can use many file types. Here are the most common ones:

- STEP

- IGES

- X_T/X_B

- SLDPRT

- IPT

- SAT

- DXF

- DWG

If you upload your design in one of these formats, the supplier can work faster. If you use a rare format, you might have to wait or change your file.

Tip: Always check your file format before you upload it. This helps you avoid mistakes.

Include Technical Drawings

Technical drawings give extra details for your custom aluminum part order. These drawings show sizes, tolerances, and special features. Sometimes, these details do not show up in the CAD model. Adding a technical drawing helps the supplier give you a correct quote. It also helps them make your part just right.

| Feature | Details |

|---|---|

| Machined prototypes | 3-5 days |

| Material options | 60+ metal and plastic materials |

| Surface finishes | 20+ options |

| Tolerances | +/-0.01mm |

| Customized design | Based on drawing |

| Free samples | Before order confirmation |

Technical drawings let you show linear tolerances to ISO 2768-1-1989-f standards. You can ask for standard hole tolerances of +/- 0.005 in. You can also ask for bore-style tolerances of +/- 0.0005 in. If your part is smaller than 0.5mm, you must write the tolerance on the drawing.

Specify Dimensions and Tolerances

You need to list all sizes and tolerances for your custom aluminum part. Clear numbers help the supplier know what you want. This helps stop mistakes. Use simple words and exact numbers. If your part needs tight tolerances, write them in the CAD file and the technical drawing.

- Write the total part size

- List hole sizes and where they go

- Say what surface finish you want

- Add notes for special features

When you give all the details, AFI Industrial Co., Ltd can give you a correct quote. They can also make your part just how you want it. This step saves time and helps stop mistakes during production.

Note: Good sizes and tolerances help you get better parts. You will also need fewer changes.

Upload and Specify for Turning of Aluminum Parts

When you upload your design, you get to choose everything for your aluminum parts. You can pick the material and the finish. This helps make sure your order is just what you want. AFI Industrial Co., Ltd and other top suppliers make this easy.

Select Aluminum Grade

Picking the right aluminum grade is important. Each grade has different strength and surface quality. Some grades are easier to machine than others. You should pick the grade that fits your project and budget. Here are some common grades people choose online:

- MIC 6 – Easy to machine, good for cast plate.

- Alloy 6061 – Machines well, comes in T4 and T6 tempers.

- Alloy 7050 – Machines okay, better than 7075 for some jobs.

- Alloy 7075 – Machines okay, strong but harder to work with.

- Alloy 2024 – Machines okay, but can chip when turning.

- Alloy 5083 – Hard to machine, may look rough.

If you do not know which grade to use, you can ask AFI Industrial Co., Ltd for help. Picking the right grade helps your aluminum parts work well and look good.

Enter Dimensions and Finish

After you upload your design, you need to type in all the sizes and pick the finish. Giving the right measurements helps the supplier make your part correctly. You should include:

- Total size of the part

- Hole sizes and where they go

- Thread sizes if you need them

- Type of surface finish

Surface finishes change how your aluminum parts look and work. Some finishes, like anodizing or powder coating, add color and protect the part. Others, like Alodine, help stop rust. Finishes can change the price and how long it takes to get your part:

- Some finishes cost more because they need extra work.

- Anodizing and powder coating usually cost $1,200 to $1,400 per metric ton.

- Alodine costs about $800 per metric ton.

- Special finishes, like wood-look, cost a lot more.

- Suppliers with their own finishing, like AFI Industrial Co., Ltd, can help you save time and money.

Note: The finish you pick can change the price and delivery time. Always look at your choices before you finish your order.

Add Special Instructions

You can write special instructions to make sure your aluminum parts are just right. These notes help the supplier know what you want for your order. Some common special instructions are:

- Tapping – Ask for threads in holes for screws.

- Countersinking – Let flat screws sit even with the surface.

- Bending – Ask for flat parts to be bent into shapes.

- Finishing services – Add anodizing, powder coating, or plating.

- Hardware insertion – Ask for nuts or standoffs to be put in.

Suppliers like AFI Industrial Co., Ltd read these notes to make sure your order is complete. You can use the notes section when you upload your design to tell them about any special needs.

Tip: Always check your special instructions before you send your order. Clear notes help stop mistakes and make sure your aluminum parts are just how you want.

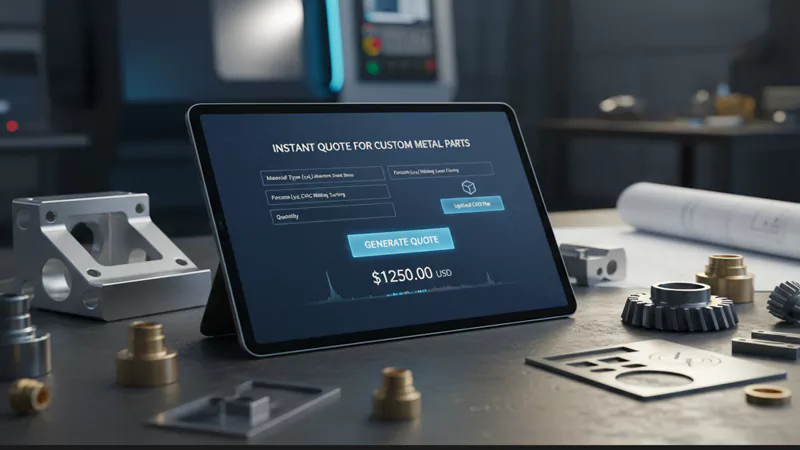

Get an Instant Quote for Custom Metal Parts

When you order custom metal parts online, you want to know the price fast. AFI Industrial Co., Ltd and other top suppliers use instant pricing tools. These tools let you upload your design and get a quote in just a few minutes. You can change your order and see how the price changes before you buy.

Review Price Breakdown

Instant pricing shows you what you will pay for each part. You see the cost for materials, machining, finishing, and shipping. The price changes when you pick different options. If you order more parts, each one costs less because setup costs are shared. You can also get better deals and discounts with bigger orders. Here is a table that shows what affects the price:

| Factor | Description | Impact on Pricing |

|---|---|---|

| Order Volume | Larger orders spread setup costs across units | Reduces per-unit price for bulk orders |

| Negotiating Power | Bigger orders allow for better negotiation | Higher discounts for larger orders |

| Production Efficiency | Large orders allow for streamlined production | Increases efficiency, lowers labor cost |

You can lock in prices for long projects. This helps you avoid price changes and plan your budget. Suppliers like AFI Industrial Co., Ltd give you stable prices and better deals if you plan ahead.

| Long-Term Pricing Strategy | Description | Impact on Pricing |

|---|---|---|

| Price Stability | Lock in prices to avoid market fluctuations | Ensures predictable costs over time |

| Better Terms and Discounts | Negotiating long-term deals may result in discounts | Lower overall pricing and better terms |

| Improved Planning | Long-term contracts allow for easier budgeting | Helps manage expenses more effectively |

Tip: Always look at the price breakdown before you finish your order. This helps you avoid surprises and control your spending.

Adjust Order Parameters

You can change your order to see how it changes the price. If you order more parts, the price for each part goes down. If you pick a different aluminum grade, the price may go up or down. Here are some things to think about when getting a quote:

- How many parts you order changes your first payment.

- Minimum order quantity (MOQ) depends on the material and supplier, which changes the total price.

- Picking the right MOQ helps you avoid extra cost and waste.

- The raw material you choose changes both the price and how fast it can be made.

- Bigger orders lower the price for each part because setup costs are shared.

- Small orders cost more for each part because of extra setup time.

You can use instant pricing tools to try different choices. This helps you find the best mix of price and quality for your custom metal parts.

Consider Shipping and Lead Time

Shipping and lead time are important when you order custom aluminum parts. You want to know how fast you will get your parts and how much shipping will cost. Most suppliers ship parts, full bars, and cut bars in 3 to 6 days. If you add black anodizing or special finishes, it takes more days to ship. Here is a table to help you plan:

| Type of Product | Days To Ship |

|---|---|

| Parts Only | 3 – 6 |

| Full Length Bars | 3 – 6 |

| Cut-To-Length Bars < 60″ | 3 – 6 |

| Cut-To-Length Bars 60″ and Longer | 3 – 6 |

| Bars & Parts with custom machining | 8 – 10 |

| Black Anodizing (add to above) | +7 – 9 |

| Cut-To-Length Bars over 60″ | +13 – 16 |

| Bars & Parts with custom machining | +13 – 16 |

- Freight orders usually ship in 2-4 business days.

- Delivery takes 2-6 business days.

- Shipping may cost less if you send it to a business address.

You should always check shipping and delivery times before you finish your order. Fast shipping and clear dates help you plan your project and avoid waiting.

Note: Instant pricing tools from AFI Industrial Co., Ltd show you shipping cost and delivery time before you pay. This makes ordering custom metal parts online easy and worry-free.

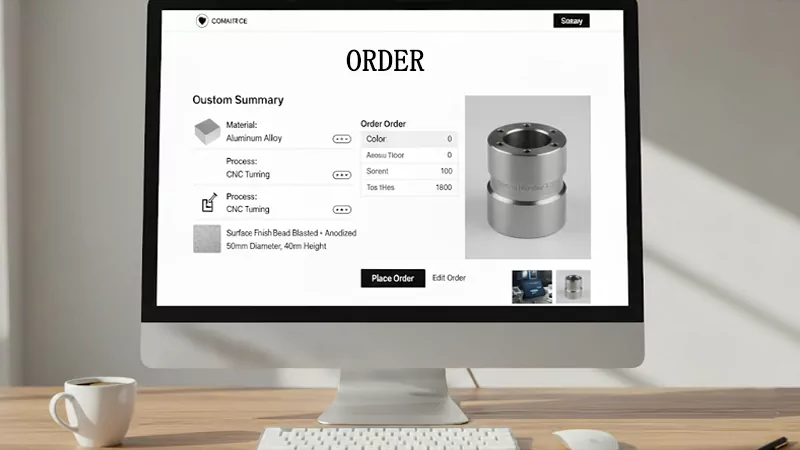

Confirm and Place Your Custom Order

Review Order Details

Before you finish, check every part of your order. Look at your design, material, finish, and how many you want. Make sure your CAD files and drawings are correct. Check the sizes and tolerances again. Read any special instructions you wrote for your project. If you find a mistake, fix it before you confirm.

AFI Industrial Co., Ltd shows you a summary on their website. You see a preview of your part, the material, finish, and shipping method. You also see how much everything costs. This step helps you avoid mistakes and get the parts you want.

Tip: Take time to look over your order summary. Careful checking helps you avoid problems and saves money.

Enter Payment Information

After you check your order, you pay for it. Online CNC machining suppliers, like AFI Industrial Co., Ltd, take many payment types. You can pick the one that works best for you. Here is a table with common ways to pay:

| Payment Method | Description |

|---|---|

| Credit Cards | All major credit cards including American Express and Discover are accepted. |

| PayPal Payments | Payments can be processed through PayPal at checkout. |

| Checks | Payment must be cleared before shipping. |

| ACH/Bank Wire Transfer | Request bank transfer information to set up a transfer. |

| International Wire Transfer | A fee applies for wire transfers. |

You type your payment details on a safe checkout page. If you use a credit card or PayPal, your order goes through fast. If you pay by check or wire, shipping starts after the money clears. Some suppliers let you finance big orders. Always pick the payment way that fits your needs.

Note: Safe payment systems keep your information private and your order safe.

Receive Part Number and Confirmation

When you pay, you get a confirmation. AFI Industrial Co., Ltd gives you a special part number for your order. You also get an email with all your order details. The email has your part number, what you ordered, and when it will arrive.

You use your part number to check your order online. If you need help, give this number to customer support. This makes it easy to get answers fast. Keep your confirmation email for your records. It helps you track your orders and plan your projects.

Tip: Save your part number and confirmation email. You will need them for tracking and help.

Track Production and Delivery

After you order from AFI Industrial Co., Ltd, you can watch every step. You get updates that tell you where your aluminum parts are. You also learn when they will get to you. This makes things easy and helps you not worry.

Order Status Updates

You get updates about your order by email or online. These updates tell you when your parts start being made. They also tell you when machining is done and when your parts ship. AFI Industrial Co., Ltd uses smart tracking tools to keep you updated. You can check your order with a part number or waybill number.

Here are some tools suppliers use for tracking:

| Technology | Description |

|---|---|

| Marken FastTrack™ | Lets you see shipment status with a waybill number. Shows where it starts, where it goes, and if it is delivered. |

| Maestro™ | Gives live updates when you enter a consignment number. |

| World Courier eContact | Sends emails when your shipment reaches important steps. No extra setup needed. |

| ADVtrack Web Service | Tracks orders using order history and dates. |

| HWBtrack Web Service | Tracks with a House WayBill number. |

| Track-POD | Sends quick updates on order status and delivery. Notifies you by SMS or email about when it will arrive. |

You can use these tools to see where your order is any time. This helps you plan your work and not have delays.

Tip: Keep your part number and waybill number. You need them to check your order fast.

Shipping Options (Free, Expedited)

AFI Industrial Co., Ltd gives you different shipping choices. You can pick free shipping for normal delivery in the US. This saves money and works for most orders. If you need your aluminum parts soon, you can choose expedited shipping. Expedited shipping puts your order first and uses faster delivery.

- Free Shipping: No extra cost for delivery in the US. Good for most orders.

- Expedited Shipping: Faster delivery for urgent needs. Costs more but saves time.

You choose your shipping option when you check out. The website shows the price and when your order should arrive.

Note: Expedited shipping helps you get your parts fast. Free shipping is best if you do not need them right away.

Estimated Delivery Time

You want to know when your aluminum parts will get to you. AFI Industrial Co., Ltd tells you when to expect your order before you pay. Most regular orders ship in 3 to 6 business days. If you add special finishes, like anodizing, it may take longer. Expedited orders usually arrive in 2 to 4 business days.

| Shipping Type | Estimated Delivery Time |

|---|---|

| Standard (Free) | 3 – 6 business days |

| Expedited | 2 – 4 business days |

| With Special Finish | Add 7 – 9 business days |

You see your delivery date in your order email and on your account page. If you want more updates, you can check online or ask customer support.

Tip: Always look at your delivery time before you finish your order. This helps you plan and not be surprised.

Tips for Ordering Custom Metal Parts Online

Double-Check Design Files

You should look over your design files before you order. Checking your files helps you avoid problems and extra costs. Many people make mistakes in their files. These mistakes can slow down the work or make the wrong parts. Some common mistakes are making parts that are hard to machine, missing important details, or using sizes that are not standard.

- Making parts that are hard to machine

- Not enough detail in the part drawing

- Using sizes that are not standard

Use CAD software to make your models. Always add clear sizes, features, and tolerances to your drawings. AFI Industrial Co., Ltd says you should check every detail. This makes sure your aluminum parts turn out right and match what the supplier can do.

Tip: Check your files to make sure they are clear and complete. Good files help you get quotes faster and get better parts.

Communicate Special Requirements

Talking clearly with your supplier helps your order be correct. Tell AFI Industrial Co., Ltd if you need something special for your aluminum parts. Use detailed drawings to show sizes, features, and tolerances. Giving updates and being open stops confusion.

| Communication Strategy | Impact on Order Accuracy |

|---|---|

| Regular communication schedule | Stops surprises and confusion |

| Detailed specifications | Makes sure the part is what you want |

| Transparency throughout the process | Builds trust and keeps everyone on track |

Keep talking with your supplier at every step. Good customer service makes ordering easier. Fast answers to your questions or changes help the supplier give you what you need.

- Clear talking is important at every step of ordering.

- Good customer service makes ordering better.

- Fast answers to questions or changes help make your order right.

Note: Always tell your supplier about special needs early. This helps AFI Industrial Co., Ltd make parts that fit what you want.

Save Order History

You should keep your order history for later. Saving your records helps you see what you bought before and makes ordering again easier. You can look at old orders and compare them to new ones. This helps you see what changed or got better. AFI Industrial Co., Ltd gives you order summaries and emails for every order.

Keep your part numbers, details, and delivery dates in a safe place. This helps you manage your projects and talk to customer support if you have questions. Saving your order history also helps you plan for new jobs and keep your parts the same.

Tip: Keep your order records organized. Good records save time and help you not make the same mistakes again.

Related Services: Custom Machining Parts

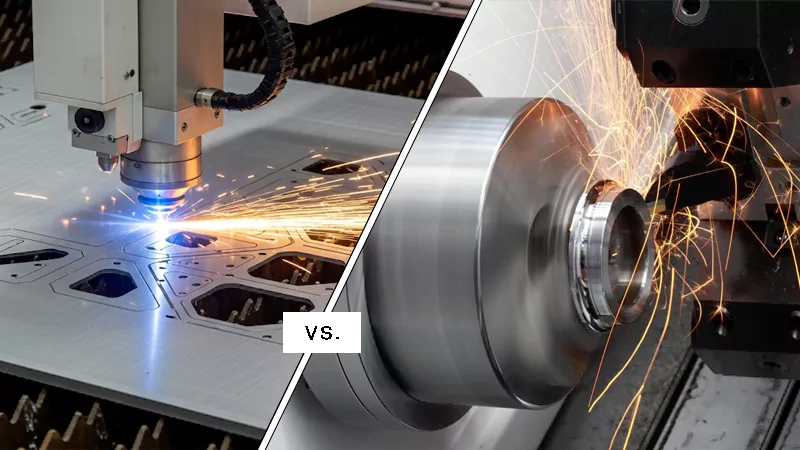

Many online suppliers, including AFI Industrial Co., Ltd, offer more than just CNC turning. You can also order custom laser cut parts for your aluminum projects. These services give you more options to match your design needs and budget.

Custom Laser Cut Parts vs. Turning Parts

You need to know the difference between laser cutting and turning before you choose a process. Laser cutting uses a focused beam to slice through aluminum sheets and plates. This method works best for flat parts, complex shapes, and thin materials. Turning uses a lathe to spin the aluminum and cut it into round or cylindrical shapes. You should pick turning for parts like shafts, bushings, or threaded rods.

Laser cutting gives you fast results for thin aluminum sheets. You can cut sheets up to 3 mm thick at speeds from 1,000 to 3,000 mm per minute. Medium-thickness materials, between 3 and 6 mm, need slower speeds from 500 to 1,500 mm per minute. Power requirements change with thickness. Thin sheets need at least 500 watts, while thick plates may need up to 8,000 watts. Different aluminum grades, such as 5052 or 7075, affect cut quality and power needs. You should also think about cost and design flexibility. Laser cutting works well for detailed shapes and quick production. Turning is better for round parts and tight tolerances.

Note: You can combine both processes for complex projects. For example, you might laser cut a flat profile and then turn features like threads or grooves.

| Process | Best For | Speed (Thin) | Speed (Medium) | Power Needs | Design Flexibility |

|---|---|---|---|---|---|

| Laser Cutting | Flat, complex shapes | 1,000-3,000 mm/min | 500-1,500 mm/min | 500-8,000 W | High |

| Turning | Round, cylindrical parts | N/A | N/A | Lower | Moderate |

How to Choose Process

You should look at your part’s shape, size, and function before you pick a process. If your design needs flat profiles or intricate cutouts, laser cutting is the right choice. If you need round parts or features like threads, turning works better. You should also consider material thickness and grade. Thinner sheets cut faster with lasers, while thick or hard grades may need more power and time.

Cost matters too. Laser cutting often costs less for simple, flat parts. Turning may cost more for complex, round shapes. Design flexibility is another factor. Laser cutting lets you create detailed patterns and holes. Turning gives you precise diameters and smooth finishes.

AFI Industrial Co., Ltd can help you decide which process fits your project. You can ask for advice or upload your design to get instant feedback. Many customers use both services to get the best results for their custom aluminum parts.

Tip: Always review your design and project needs before you choose laser cutting or turning. This helps you save time and money.

Ordering custom turned aluminum parts online with AFI Industrial Co., Ltd is quick and easy. You just upload your design, get a price right away, and follow your order online. Customers say there are lots of good things about this:

- Custom aluminum parts make products work better and last longer.

- You can change parts to fit your job, like cars or electronics.

- Aluminum parts are strong, last a long time, and help cut down on waste.

| Customer Feedback |

|---|

| “I love your reliability and instant quoting. You guys truly rock!” |

| “Speed of iteration is a massive benefit. I’ve iterated five times in one hour.” |

Start your next project now and see how easy online ordering can be.

FAQ

Look for a fabricator with good ratings and instant quotes. Make sure they have proven quality. If they have ISO certification, your parts will meet standards. AFI Industrial Co., Ltd gives reliable service and high-quality parts for every project.

Most fabricators take STEP, IGES, SLDPRT, and DXF files. Always check the website before you upload your parts. Picking a fabricator that accepts many formats helps you avoid delays. This makes sure your parts are made right.

Give clear CAD files and technical drawings. Pick a fabricator with first article inspection and ISO 9001 certification. This helps guarantee quality. AFI Industrial Co., Ltd checks every part for accuracy before shipping.

Upload your CAD files and list all sizes and finishes. Add any special instructions. A fabricator that guides you through each step makes ordering easy and accurate.

Delivery time depends on the fabricator and your order. Many fabricators, like AFI Industrial Co., Ltd, ship parts in 3 to 6 business days. You can pick expedited options if you need parts sooner.

Yes, most fabricators let you track your order. You get updates by email or through your account. AFI Industrial Co., Ltd lets you follow your parts from production to delivery. You always know where your order is.

Compare quality, price, shipping, and customer support. Pick a fabricator with a strong reputation, like AFI Industrial Co., Ltd. This helps your parts arrive on time and meet your needs.

AFI Industrial Co., Ltd gives instant quotes, fast production, and high-quality parts. You get support at every step. Picking a fabricator like AFI Industrial Co., Ltd helps you finish projects quickly and easily.