Milling machining parts are the final pieces made by shaping raw materials with milling technology. Rotary cutters spin in a milling machine to take away material from a workpiece. This changes it into a part with exact shapes and sizes. Milling is important in manufacturing because it is very accurate. It can also make complex parts for things like airplanes and medical tools. Milling is a subtractive process. This means you cut away extra material and keep only the shape you want.

Key Takeaways

- Milling machining parts are made by cutting material from a solid block. This process helps create exact shapes.

- Milling is very important in car, airplane, electronics, and medical device industries. It is used because it is accurate and can make hard shapes.

- The milling process has a few steps: setup, material removal, and finishing. Each step is important for making good parts.

- Picking the right milling machine and cutting tool is very important. It helps make the work faster and the part better.

- Milling machines can use CNC controls for more accuracy. This lets people make the same part many times.

- Keeping milling machines clean and fixed stops them from breaking. This helps them work well for a long time.

- Safety is important when using milling machines. People should wear safety gear and use guards to stop injuries.

- Knowing about different materials helps pick the best one for milling. This makes the finished part better.

Table of Contents

Milling Machining Parts

Definition

Milling machining parts help you get exact shapes and sizes. These parts are made by using rotary cutters to cut away material from a solid block. Milling is special because it gives very accurate results. It also lets you make shapes that are hard to make in other ways. The table below shows what makes milling machining parts different from other machined parts:

| Key Component | Description |

|---|---|

| Precision of the milling process | Milling gives very exact sizes for the parts you make. |

| Ability to create complex geometries | Milling can make detailed shapes that are hard to do with other methods. |

| Specific material removal techniques | Milling uses its own ways to cut material, which makes it different from other machining. |

You use milling when you need parts with tight fits and detailed shapes. Milling machining parts are important in many products because they fit well and work every time.

Applications

Milling machining parts are used in many industries that need strong and accurate parts. Milling lets you make parts for many jobs. Here are some common uses:

- Automotive parts production: Milling is used to make engine blocks, transmission cases, and suspension parts that must be exact.

- Aviation components: Milling helps make airplane wings and landing gear from light metals, so they are very accurate.

- Electronic components: Milling is used for circuit boards and connectors, where being exact is important for how things work.

- Medical devices: Milling machining parts include prostheses and surgical tools that need to be both exact and safe for the body.

Milling is important in fields where quality and trust matter most. Milling machining parts help you meet tough rules and always get good results.

Importance

Milling machining parts help you make things faster and more accurately. Milling has many good points that make it important today:

- Precision and efficiency: Computer-controlled milling gives you exact and steady results.

- Repeatability: Milling makes sure every part is almost the same, so your quality stays high.

- Cost-effectiveness: Milling lets you plan tool paths to save material and lower costs.

- Complex geometries: Milling can make tricky shapes that old methods cannot do.

- Versatility: You can use milling with many materials and tools.

- Quick prototyping: Milling helps you make test parts fast and with high accuracy, so you can finish projects sooner.

- Scalability: You can change how much you make with milling to match what you need.

Tip: If you pick milling machining parts, you get more control and choices in how you make things. You can finish work on time and make products that fit your needs.

Milling machining parts help you stay ahead in jobs that need the best work. You can count on milling to give you the results you want, whether you work in cars, planes, electronics, or health care.

Milling Process

Principles

You use milling to shape materials with high accuracy. Milling uses rotary cutters that spin quickly to cut away material from a solid block. You control the movement of the cutter and the workpiece to get the shape you want. The milling process is subtractive, so you start with a solid piece and remove what you do not need.

- Milling uses rotating cutters to take away material from the workpiece.

- Feed rates decide how fast you remove material during milling.

- The depth of cut tells you how much material you remove in each pass.

- CNC milling uses computer controls to guide the cutter and workpiece.

- Multi-point cutting tools move along several axes for complex shapes.

- You use pre-programmed software, often G-code, to control the operation.

You can use milling for many types of machining. Milling gives you control over the final part’s size and shape. You can make simple or complex parts with the right setup.

Note: Milling works best when you match the cutter type, feed rate, and depth of cut to your material and design.

Stages

You follow several steps in the milling process to get the finished part. Each stage helps you reach the final shape and quality you need.

Setup

You start by planning and preparing for milling. You design the part using CAD software. You choose the right material and set the exact dimensions. You clamp the workpiece in place and attach the correct cutter. You set machine parameters like speed and feed rate. You check everything to make sure the setup matches your design.

| Setup Step | Description |

|---|---|

| CAD Design | You create a digital model of the part. |

| Material Selection | You pick the right material for your needs. |

| Workpiece Clamping | You secure the material in the milling machine. |

| Cutter Attachment | You install the correct rotary cutter. |

| Parameter Setting | You set speed, feed rate, and depth of cut. |

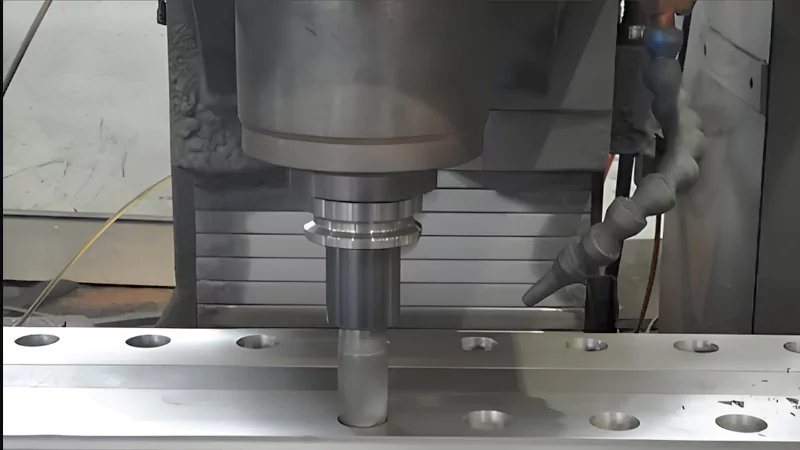

Material Removal

You begin the main machining process by removing material. The cutter spins at high speed. The workpiece moves in relation to the cutter. You control this movement with CNC or manual controls. The cutter removes small pieces of material with each pass. You may use coolant fluids to keep the cutter cool and extend its life. You repeat passes until you reach the desired shape.

- The cutter rotates and moves along the planned path.

- The workpiece shifts to match the design.

- Material comes off in small chips.

- You use coolant to manage heat and protect the tool.

- You check progress after each pass.

Tip: You can adjust feed rates and depth of cut to improve efficiency and surface finish during milling.

Finishing

You complete the milling process by finishing the part. You remove the workpiece from the machine. You inspect it to make sure it matches your design. You may polish or clean the part for a smooth surface. You check for accuracy and quality. If needed, you make small adjustments or use other machining processes to perfect the part.

| Finishing Task | Purpose |

|---|---|

| Inspection | You check size and shape for accuracy. |

| Cleaning | You remove chips and coolant residue. |

| Polishing | You improve surface finish. |

| Adjustment | You fix any small errors. |

You follow these stages to get reliable results from milling. You can use milling for many machining jobs, from simple shapes to complex parts. You control each step to make sure your parts meet high standards.

Callout: If you understand each stage of the milling process, you can improve your results and avoid common mistakes.

Milling Equipment

Milling Machines

A milling machine helps you shape materials very accurately. Different milling machines are made for different jobs. You can pick from vertical, horizontal, or cnc milling machines. The table below lists the most common types used in factories:

| Type of Milling Machine | Description |

|---|---|

| 3-axis Milling Machine | Moves in X, Y, and Z axes for simple operations. |

| 4-axis Milling Machine | Adds a rotary axis for more complex parts. |

| 5-axis Milling Machine | Uses two rotary axes for high-speed, complex part production. |

| 6-axis Milling Machine | Moves in all axes for high precision and mass production. |

| Fixed Bed Milling Machine | Stationary bed, easy maintenance. |

| Knee-Type Milling Machine | Vertical movement for versatility. |

| Planer-Type Milling Machine | Cuts flat surfaces, common in woodworking. |

| C-Frame Milling Machines | Vertical movement, used for mass production. |

| Travelling Column Milling Machines | Horizontal movement for long parts. |

| Gantry Milling Machine | Supports multiple cutters for large parts. |

| Manual Milling Machine | Operator-controlled, low precision. |

| Tracer-Controlled Milling Machines | Uses a replica for guidance, low precision. |

| Milling machine with DRO | Manual control with better precision. |

| CNC Milling Machines | Uses programming for precise and fast operations. |

Vertical

A vertical milling machine is good when you need to see your work. The cutting tool moves up and down. You can watch your progress easily. These machines are great for small jobs and custom tools. They cost less to buy and let you see what you are doing. For turret mills, you must move the bed, so they are not as strong for big jobs.

Horizontal

A horizontal milling machine is best for big parts and lots of work. The cutting tool is sideways. Chips fall away by themselves, so things stay clean. These machines have more power for cutting. They cost more, and you cannot see the workpiece as well while working.

CNC

CNC milling machines use computers to control the cutting tool. You write a program, often with G-code, to tell the machine what to do. CNC milling makes tricky shapes fast and with the same results every time. These machines are great for making many parts and for detailed work.

Tip: Pick the milling machine that fits your job. Vertical machines help you see your work. Horizontal machines give you more power. CNC machines are best for fast and repeatable work.

Cutting Tools

You need the right cutting tool for each milling job. The cutting tool shapes the material and changes how the part looks. There are many types, and each one does something special:

- End mill: This tool cuts from the end and the sides.

- Face mill: This tool cuts with its sides.

- Ball cutter: This tool keeps corners round on faces that meet.

- Slab mill: This tool is for cutting big flat areas.

- Side-and-face cutter: This tool cuts on the side and face, but is not used much now.

- Involute gear cutter: This tool is for making gears.

- Fly cutter: This tool works like a face mill but has one or two bits.

- Hollow mill: This tool makes round shapes.

- Roughing end mill: This tool cuts fast with rough teeth.

- Woodruff cutter: This tool makes keyslots.

- Thread mill: This tool is for making threads in holes.

- Chamfer mill: This tool cuts angled edges and removes sharp bits.

- Keyseat cutters: This tool makes undercuts and t-slots.

Note: Pick your cutting tool based on what you are cutting and the shape you want. The right tool helps you work faster and makes the part look better.

Workholding

You must hold the workpiece tightly during milling. Workholding keeps the part still and helps you get good results. There are different ways to do this:

| Workholding Method | Description | Advantages |

|---|---|---|

| Magnetic Workholding | Uses magnetic force to hold parts, ideal for heavy cutting processes. | Prevents part slippage, ensures machining accuracy and safety. |

| Vacuum Workholding | Uses atmospheric pressure, effective for flat or thin materials. | Provides uniform clamping force, minimizes material deformation for high-precision machining. |

| Tape and Adhesive Techniques | Uses adhesives to fix delicate materials, useful in PCB fabrication. | Versatile and damage-free for thin materials. |

| Bolting | Uses bolts to secure the workpiece, often with aluminum blocks for stability. | Allows better leveling and stability during machining. |

| Pneumatic and Hydraulic Clamping | Applies uniform force across points, simplifies automation in cnc milling. | Ideal for repetitive tasks, ensures consistency and speed. |

| Specialized Tools | Modular fixtures and positioning devices for complex cnc milling operations. | Saves time by allowing simultaneous machining of multiple parts. |

Pick the workholding method that matches your part and machine. Magnetic and vacuum workholding help you get very accurate results. Pneumatic clamping is best for cnc milling and doing the same job many times. Special tools let you set up more than one part at once and save time.

Callout: Using the right workholding method keeps you safe and helps your work be more accurate. Always check that your part is tight before you start the milling machine.

Milling Operations

Face Milling

Face milling makes the top of your workpiece flat and smooth. You do this when you need a good starting point for more work. The face milling cutter spins straight up and down. Only the bottom of the tool touches the material. You can use face milling on both vertical and horizontal machines. This means you can pick the best machine for your job.

Face milling is special because it works on the surface closest to the spindle. You set a reference point called Z0. This helps you line up other steps later. Face milling is good for taking off a little bit of material. It also gives a nice, smooth finish. People often start with face milling before doing more detailed work.

| Aspect | Face Milling | Peripheral Milling |

|---|---|---|

| Machine Orientation | Perpendicular to the workpiece | Parallel to the workpiece |

| Cutting Action | Only the top of the tool engages in milling | Sides of the tool engage with the workpiece |

| Machine Compatibility | Can be done on both horizontal and vertical spindles | Limited to horizontal spindles |

| Material Removal | Suitable for surface machining and small amounts | Suitable for removing large amounts of material |

| Tool Design | Cutting edges on both sides and face | Cutting edges primarily on the sides |

Tip: Start with face milling to get a smooth top. This makes the next steps easier and more exact.

- Face milling makes the top flat and smooth.

- You set a reference point (Z0) for later steps.

Peripheral Milling

Peripheral milling takes away lots of material from the sides. The sides of the cutter do the cutting. The tool moves along the side of the workpiece. This works best on horizontal machines. You use peripheral milling for slabbing, profile milling, slotting, straddle milling, and slitting. It is also used for rough work in mold making.

Peripheral milling is great for deep slots, threads, and gear teeth. You can make shapes, slots, and tricky profiles this way. It gives a smooth finish and exact sizes. You use peripheral milling when you need to remove extra material fast.

- Slabbing cuts big pieces off the workpiece.

- Profile milling shapes the sides in detail.

- Slotting makes grooves or slots.

- Straddle milling cuts two sides at once.

- Slitting is for thin, precise cuts.

- You can also mill slopes or facades.

- Rough machining is used in mold making.

Note: Pick peripheral milling when you need to cut a lot or make tricky shapes on the sides.

Slotting

Slotting lets you make grooves, keyways, and inside shapes. You start with a side-and-face cutter to rough out the slot. For finishing, you use a shell mill or face milling cutter. Keyway slotting needs to be very exact, so you use a woodruff key cutter. You start by plunging in, then take a light pass to finish the width.

For inside grooves, you use tiny end mills in hard spots. Sometimes, you drill a small hole with EDM before slotting. For thin and shallow slots, you use single-flute micro-end mills. These tools help clear chips and make the surface smooth. If you need to remove material fast and do not need tight sizes, you use long-edge cutters for rough slotting.

Many industries use slotting. Factories use it to make keyways, splines, and grooves in parts. Car makers use slotting for engine and transmission parts. Airplane companies use slotting for blades and landing gear, where accuracy is important. Tool and die makers use slotting for detailed shapes in molds.

- Slotting uses a side-and-face cutter first, then a shell mill or face milling cutter to finish.

- Keyway slotting needs to be exact, often using a woodruff key cutter, with a plunge start and light pass to finish.

- Inside grooves are made with small end mills in tight spots, sometimes starting with a small hole from EDM.

- Thin and shallow slots use single-flute micro-end mills to clear chips and smooth the surface.

- Fast slotting with long-edge cutters is for quick work without needing tight sizes.

Callout: Always pick the right cutter and method for slotting, based on your part’s shape and how exact it needs to be.

Drilling

Drilling is a key operation you can perform with a milling machine. When you need to make round holes in a workpiece, you use drilling. Milling machines let you drill with great accuracy. You can set the exact spot for each hole. This helps you make parts that fit together perfectly.

You often use drilling as the first step in creating holes. After drilling, you can use milling to shape or enlarge the hole. Milling lets you add slots, pockets, or special shapes around the hole. This makes your parts more useful and precise.

You use drilling in many industries. In factories, you drill holes for bolts, screws, and pins. In car shops, you drill engine blocks and brackets. In electronics, you drill circuit boards. In oil and gas, drilling goes even further. Sometimes, you need to remove steel obstructions from a well. You use milling to clear these blocks so you can keep drilling deeper. This process helps you reach your target safely.

Here are some important roles of drilling in milling operations:

- You create round holes in metal, plastic, or other materials.

- You use milling to refine and shape the drilled holes.

- Milling helps you clear obstructions during drilling, especially in oil and gas wells.

- You can combine drilling and milling in one setup to save time and improve accuracy.

Tip: Always check your milling machine settings before you start drilling. This helps you avoid mistakes and keeps your parts safe.

You can use different tools for drilling on a milling machine. The most common tool is the twist drill. You can also use center drills to start holes and keep them straight. Spot drills help you mark the exact spot for each hole. After drilling, you can use end mills or reamers to finish the hole with milling.

| Drilling Tool | Purpose |

|---|---|

| Twist Drill | Makes standard round holes |

| Center Drill | Starts holes and keeps them straight |

| Spot Drill | Marks the exact spot for drilling |

| End Mill | Enlarges or shapes holes with milling |

| Reamer | Finishes holes for a smooth surface |

You can use drilling and milling together to make complex parts. For example, you might drill a hole, then use milling to cut a slot or pocket next to it. This gives you more options in your machining projects.

Drilling with a milling machine gives you control and flexibility. You can make holes of different sizes and shapes. You can also work with many materials. When you combine drilling and milling, you get strong, accurate parts that meet your needs.

Materials for Milling

When you pick materials for milling, you must think about how each one acts. The right material helps you make good parts. You can mill metals, plastics, and composites. Each group has its own good points and problems.

Metals

Metals are used most often in milling. They are strong and last a long time. The table below lists some common metals for milling and why they work well:

| Metal | Properties |

|---|---|

| Aluminum | Strong but light, easy to cut, not expensive. |

| Stainless Steel | Strong, does not rust, easy to cut, many types. |

| Brass | Easy to cut, does not rust, looks nice, smooth finish. |

| Titanium | Very tough, hard, does not rust, lighter than other steels. |

Aluminum

People use aluminum a lot because it is light and easy to cut. It is strong for its weight, so parts are not heavy. You can cut it fast, which saves time and money. Most aluminum alloys let you use high speeds and carbide tools. This is good for making many parts. But you need to watch your tools and settings to stop problems.

Tip: Aluminum is good for fast jobs. You get smooth parts and save money.

Steel

Steel is strong and tough. You use it when you need parts that last or hold heavy things. Stainless steel does not rust, so it works in wet places. There are many kinds of steel, each with its own good points. Milling steel needs more power and careful planning. But you get strong parts that work well.

Brass/Copper

Brass and copper are good if you want easy cutting and nice looks. Brass is easy to cut and does not rust. You get smooth and shiny parts. Copper is softer and carries electricity well, so it is used for wires and parts. Brass can be harder to cut than aluminum, so you may need to change your settings.

Note: Brass and copper are good for small, detailed parts. Use the right way to get the best finish.

Plastics

You can also mill plastics. Plastics are light and easy to shape. They are good for parts that do not need to be very strong. Some plastics, like high-performance polymers, are tough and last a long time. POM is used in cars because it is stiff and strong. PA-6 is easy to cut and keeps electricity in, so it is used for small parts. PMMA is clear and used for covers. PTFE can take high heat, and nylon is strong but soaks up water. Delrin is easy to cut and stays in shape. HDPE is strong and used outside. Polycarbonate is tough and clear, so it is used when you need both.

- High-performance polymers: Good for hard jobs and lots of use.

- POM: Used in cars for strength.

- PA-6: Good for electric parts.

- PMMA: Clear and blocks UV.

- PTFE: Handles heat.

- Nylon: Used for many things but takes in water.

- Delrin: Easy to cut and keeps its shape.

- HDPE: Strong and used outside.

- Polycarbonate: Tough and clear.

Composites

Composites mix two or more things to get special features. You often use fiber-reinforced plastics in milling. Composites do not act like metals or plastics. They have different strengths in different directions. How you mill them depends on fiber direction, tool shape, and how you cut. You get different chips and must change your milling steps. Composites usually take off less material each time than metals, so you must plan well.

Callout: Milling composites needs skill and the right setup. You must match your tools and settings to each composite.

You can pick from many materials for milling. Each one gives you different results. If you know how each acts, you can choose the best one and get good parts every time.

Advantages and Limitations

Benefits

Using a milling machine gives you many good things. Milling is very exact. You can make parts that fit together really well. Some machines can cut as close as 0.004 mm. This is important for jobs that need tight fits. Milling machines work for a long time without stopping. They do many steps by themselves. This helps you finish work faster and saves time. Milling also helps you waste less material. The machine cuts only what you need. This saves money and keeps your shop clean.

Here is a table that lists the main benefits of milling:

| Benefit | Description |

|---|---|

| High Precision | Make detailed parts with tight fits. |

| Increased Efficiency | Machines run long hours and do tasks automatically. |

| Reduced Material Waste | Only cut what you need, so you save money and material. |

| Consistent Uniformity | Every part is the same because of digital controls. |

| Capability for Complex Designs | Make shapes that are hard to do with other tools. |

| Error Reduction | Fewer mistakes because the machine is automated. |

| Long-term Cost-effectiveness | Save money on labor, waste, and mistakes over time. |

| Improved Safety | Operators stay safe because they do not touch the tools. |

Milling machines can work with many materials. This means you can do lots of different jobs. You can make one test part or many parts fast. This helps you finish orders on time and change plans if needed.

Tip: Milling helps you make tricky parts with less waste and fewer mistakes. You can count on your milling machine to give you the same part every time.

Challenges

There are some problems you might have with milling. Tools can wear out or break if you do not check them. You need to look at your machine often and use the right tool for each job. Writing programs for the machine can be hard. You must give clear steps, or mistakes can happen.

Checking each part takes time and work. You must measure every part to make sure it is right. If you try to go too fast, you might break a tool or ruin a part. You need to find the right speed and keep your work accurate.

Here are some common problems you may see:

- Tools wear out and need checking to keep parts exact.

- Programming is hard, so you need skilled workers.

- Checking quality takes more time and effort.

- If you rush, you might slow down or make mistakes.

Note: If you take care of your machine and plan well, you can stop most problems before they start.

Comparison

You might wonder how milling is different from other ways to shape parts. Milling is best when you need tricky shapes or very close fits. Milling machines can cut many shapes that other machines cannot do. Turning is better for round parts and is faster for simple jobs. Grinding makes the smoothest finish but is slow and used for final steps.

- Milling is good for tricky shapes and close fits.

- Turning is faster for round parts and keeps them round.

- Grinding gives the smoothest finish but takes more time.

Callout: Pick milling if you want to make detailed parts with close fits. Use turning for simple round parts and grinding for the smoothest finish.

Safety and Issues

Safety Practices

You need to follow safety rules when using a milling machine. These rules help stop injuries and keep your area safe. Here are some important safety steps:

- Put guards on the milling machine. Guards block moving parts and stop chips from hitting you.

- Use cutter guards to cover sharp tools. These guards keep you safe from the cutters.

- Place safety signs near the machine. Signs warn you and others about dangers.

- Check the motor controls before you start. Good controls help you stop the machine fast if needed.

- Use safety shields for extra protection. Shields keep chips away from your face and hands.

Tip: Always wear safety glasses. Keep loose clothes away from the machine. Never reach over moving parts.

Common Problems

You might have problems when working with milling. Each problem can hurt your parts or make your area unsafe. The table below lists common problems and ways to fix them:

| Problem | Solution |

|---|---|

| Tool Wear and Tear | Check tools often and use good ones to keep cuts right. |

| Incorrect Machine Calibration | Calibrate the machine often and use digital probes for better results. |

| Improper Programming or G-Code Errors | Check your G-code and use software to find mistakes before milling. |

| Inconsistent Material Quality | Look at your materials and pick the best ones for your job. |

| Improper Coolant Use | Keep coolant moving and check the system to stop overheating. |

| Inaccurate Fixturing | Use strong fixtures and check them often to keep the part still. |

Note: If you fix problems early, you can stop big mistakes and keep your machine working well.

Maintenance

Doing regular maintenance keeps your milling machine safe and working right. You should follow these steps to make your machine last longer and stop breakdowns:

- Lubricate moving parts often. Lubrication stops friction and overheating.

- Calibrate your machine to keep cuts exact and stop bad parts.

- Clean the machine after each use. Take away chips and dirt to stop clogs and fire.

- Check wires and controls. Good wiring keeps your machine safe and working.

- Train workers on safety rules. Training helps everyone know what to do in emergencies.

- Adjust belts and pulleys. Good alignment stops wear and lowers accident risk.

- Keep coolant and filters working well. Good coolant flow stops overheating and helps milling.

- Look for worn parts and replace them. Checking often helps you find problems early.

- Follow the maker’s maintenance plan. This helps you use the right steps for your machine.

- Make a routine maintenance plan. Regular care cuts downtime and keeps your machine ready.

Callout: Regular maintenance can lower downtime by up to 30%. If you take care of your machine, you save money and stop sudden breakdowns.

Milling machining parts turn raw materials into exact, good parts. You use milling because it works for many jobs and is very accurate. Milling takes away material to make the right shape. Fine milling helps you get very close sizes. Milling machines are used in many fields and for many kinds of parts.

If you know about the process, tools, and materials, you can make better choices:

| Aspect | How It Helps You Decide |

|---|---|

| Tool Selection | Changes how good and exact your parts are. |

| Maintenance | Makes machines last longer and keeps parts the same. |

| Tool Path Selection | Fits the material so you get the best results. |

Milling gets better with new machines and faster ways to work. You can learn more by reading about milling steps, machine types, and special tools. This helps you know more and do better work.

FAQ

Milling uses rotary cutters to remove material from a workpiece. You shape flat or complex surfaces. Turning spins the workpiece while a tool cuts it. You use turning for round parts.

You can mill plastic parts. Milling machines work with many plastics, including nylon, POM, and polycarbonate. You get smooth surfaces and accurate shapes. Always choose the right cutter for each plastic.

You select a cutter based on the material and the shape you need. End mills work for general cutting. Ball cutters help with rounded edges. Face mills create flat surfaces. Check the cutter size and coating.

Tool wear happens because friction and heat build up during cutting. You can reduce wear by using coolant, picking the right speed, and checking tools often. Worn tools make parts less accurate.

You should wear safety glasses, gloves, and ear protection. Always keep loose clothing away from moving parts. Use guards and shields on the machine. Safety gear protects you from chips and sharp tools.

You can use CNC milling for small batches. CNC machines let you make one part or many parts with high accuracy. You change programs quickly for different jobs. This saves time and reduces errors.

You keep machines in good condition by cleaning them after each use. Lubricate moving parts. Check for worn tools and replace them. Follow the manufacturer’s maintenance plan. Regular care helps your machine last longer.

Titanium and hardened steel are hardest to mill. You need strong cutters and slower speeds. These materials wear tools faster. You must plan your milling steps and use coolant to protect your tools.