When deciding between a fillet vs a chamfer, you should pick a fillet if you want more strength. Fillets help lower stress in your design, making parts last longer and improving safety. Use a chamfer when you want parts to fit together easily, as chamfers save time during manufacturing and work best for outside edges. Chamfers also cost less to make initially. The right choice between fillet vs chamfer can change how your design performs and how much money you spend.

Check the table below to see how fillets and chamfers affect costs in engineering projects:

| Aspect | Chamfer | Fillet |

|---|---|---|

| Tooling | One tool works for many sizes, easier | Special tools needed, harder |

| Machining Time | Quicker, less time to set up | Slower, more steps needed |

| Upfront Manufacturing Cost | Costs less at first | Costs more at first |

| Long-term Cost Impact | Costs more later because of sharp edges | Costs less later because it lasts longer |

| Risk and Performance | Sharp edges can cause more mistakes | Safer, lowers stress in the part |

Tip: Understanding the difference between fillet vs chamfer helps you avoid mistakes and keep your project on budget.

Key Takeaways

- Fillets make edges smooth and round. This lowers stress and makes parts stronger. Fillets also help keep parts safe.

- Chamfers make edges angled. This helps parts fit together fast. Chamfers can save time and money when making parts.

- Use fillets for parts that hold heavy weights. Fillets are good for parts that need to last long. They also give parts a soft and finished look.

- Pick chamfers for quick assembly. Chamfers help parts line up easily. Use them when you want a sharp and technical look.

- Fillets need special tools to make. They take more time to machine. Chamfers use regular tools and are faster to make.

- Fillets may cost more at first. But they save money later by needing fewer repairs. Fillets also help parts last longer.

- Always think about your material and design needs. Safety and budget are important too, when choosing fillet or chamfer.

- Follow industry rules and use the checklist given. This helps you avoid mistakes and pick the best option for your project.

Table of Contents

Fillet vs Chamfer

Fillet

A fillet is a smooth, curved area between two surfaces. You see fillets with rounded corners on many parts. Fillets help spread out stress and make parts stronger. Using a fillet lowers the chance of cracks. It also makes your design last longer. Fillets remove sharp edges, so parts are safer to touch. There are two main types of fillets. A concave fillet curves inward. A convex fillet curves outward. Fillets work well where you want better fluid flow. You find them in pipes or air ducts. Fillets help coatings stick, which protects against rust. Fillets give parts a soft, finished look. They also make your parts stronger.

Chamfer

A chamfer is a flat, angled cut on an edge. It replaces a sharp edge with a sloped surface. Most chamfers are at a 45° angle, but other angles work too. Chamfers help parts fit together during assembly. Adding a chamfer guides screws, pins, or bolts into place. This lowers the chance of parts not lining up. Chamfers also remove sharp edges, but the edge can still feel sharp. In big production runs, chamfers save time and money. You can cut them fast with standard tools. Chamfers give parts a technical, angular look. Chamfers are best when you want quick assembly and lower costs.

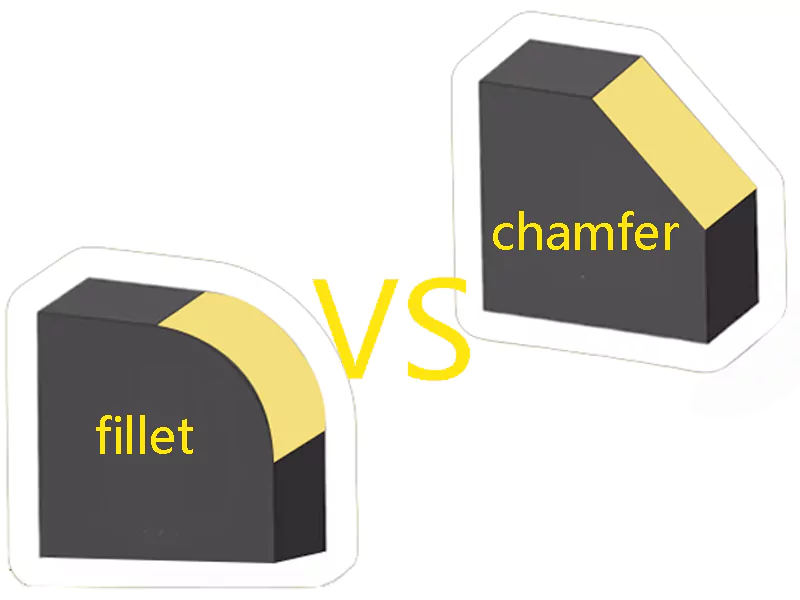

Visual Differences

You can tell fillet vs chamfer apart by looking at the edges. Fillets make smooth, rounded corners. Chamfers make flat, sloped edges. Fillets give parts a soft, natural look. You see them in handles or fancy products. Chamfers give parts a sharp, technical style. They are common in machine parts or electronics. The table below shows how fillet vs chamfer compare in shape and use:

| Feature Criterion | Fillet | Chamfer |

|---|---|---|

| Shape | Rounded edge or corner with a radius, making a smooth curve | Angled or sloped edge making a flat, straight line, often at 45° angle |

| Primary Function | Lowers stress, makes parts last longer, looks nice, feels good, helps fluid flow, and helps coatings stick | Removes sharp edges for safety, helps assembly by guiding fasteners, gives a clean, technical look |

| Stress Relief | Very good: spreads stress over a bigger area, lowers peak stress, and helps parts last longer | Not as good: does not spread stress well, stress stays at chamfer edges |

When you pick fillet vs chamfer, think about your project needs. Fillets help with strength, safety, and a smooth look. Chamfers help with fast assembly, saving money, and a technical style. Both change how your edges work and look. Choose the one that fits your design goals.

Decision Factors

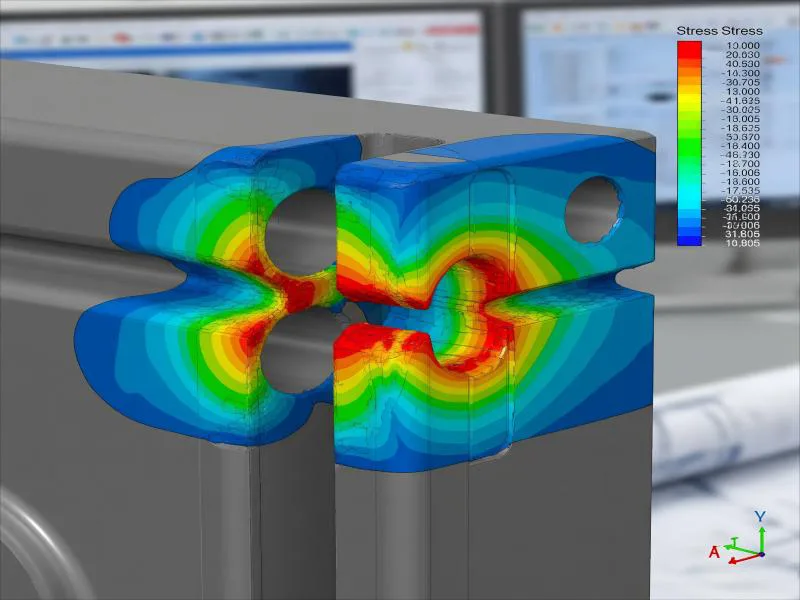

Stress

Stress is critical in engineering. Adding a fillet makes a smooth, round corner. This shape helps spread out the force. It lowers the chance of cracks or breaks. Sharp corners can cause high stress in one spot. Fillets let stress move around the corner more easily. This makes your part stronger and safer.

Fillets are better than chamfers for lowering stress. A chamfer makes a flat, sloped edge. This edge still has a sharp change, so stress can build up. If your part will face a lot of force, use a fillet. Fillets help your part last longer and stop it from breaking. They also lower the chance of damage over time. If you want your part to be strong and safe, pick a fillet.

- Fillets:

- Spread out stress by making corners rounder.

- Lower the risk of cracks and damage.

- Make parts stronger and more reliable.

- Chamfers:

- Make sloped edges that do not spread stress well.

- It can cause more stress and bending.

- Do not work as well for stress relief.

Note: Use fillets for parts that get heavy loads or lots of use. This keeps your project safe and strong.

Assembly

Assembly is also critical in engineering. You want parts to fit together easily and safely. Chamfers help guide parts into the right place. Adding a chamfer makes it easier to put in screws or pins. Chamfers help line up parts and stop damage during assembly. This makes building faster and helps avoid mistakes.

Fillets help with assembly differently. Rounded corners from fillets make parts safer to touch. You are less likely to get cut or hurt. Fillets also help parts fit together smoothly. This is good when you need a tight fit or smooth movement. If you want fast and easy assembly, use chamfers. For a safe and smooth fit, use fillets.

| Feature | Fillet | Chamfer |

|---|---|---|

| Assembly Speed | Slower, but safer and smoother fit | Faster, helps guide parts and screws |

| Safety | Removes sharp corners, safer to handle | May leave some sharpness, less safe |

| Alignment | Helps with smooth changes | Helps line up parts and stops mistakes |

| Use Case | For strong, safe assemblies | For quick, high-volume assemblies |

Tip: Use chamfers for fast assembly. Use fillets for safety and smooth edges.

Manufacturing

How you make your part matters when choosing fillet or chamfer. Fillets need special tools to make round edges. This can take more time and cost more money. CNC machines are good for making fillets, but you need the right tool size. Fillets are easier to make if you use common sizes. They also help tools last longer and make parts stronger.

Chamfers are quicker and easier to make. You can cut a chamfer with one tool, often at a 45° angle. This saves time and money. Chamfers are good for making lots of parts fast. But making perfect chamfers on hard materials can be hard. You might need extra steps or careful measuring. Chamfers can also waste more material if not planned well.

- Fillets:

- Need special tools and careful planning.

- Work best with CNC machines.

- Make parts stronger and last longer.

- Chamfers:

- Easy to make with normal tools.

- Faster and cheaper for most edges.

- It can be harder if you need many angles.

Remember: Use chamfers for easy manufacturing on most outside edges. Use fillets where you need strength and long-lasting parts.

Cost

Cost plays a big role when you choose between fillets and chamfers. You want your design to work well, but you also need to keep your project on budget. Fillets and chamfers affect cost in different ways. You should look at how each feature changes the price of making your part.

- Chamfers usually cost much less to machine than fillets. You can cut a chamfer with a single pass using a simple tool. This saves time and money, especially on outside edges.

- Fillets need special tools like ball-end mills or round-over bits. These tools take longer to set up and wear out faster. You may need more than one pass to make a smooth curve.

- For inside corners, the cost difference is smaller. Both fillets and chamfers need special tools and extra steps.

- If you need to remove sharp edges by hand, chamfers are faster and cheaper. You can use simple tools or even do it by hand.

- The total cost depends on your part design, the machines you use, and how many parts you need to make.

- Sometimes, fillets cost more at first but save money later. They make parts last longer and reduce the need for repairs.

You can see the main cost differences in the table below:

| Cost Factor | Fillets | Chamfers |

|---|---|---|

| Tooling and Equipment | Needs special tools, higher tool wear, more expensive | Uses standard tools, longer tool life, less expensive |

| Machining Time | Slower speeds, more passes, longer production | Faster speeds, often one pass, shorter production |

| Programming and Setup | More complex programming, longer setup | Simpler programming, quicker setup |

| Material Removal | Removes more material, higher material costs | Removes less material, more cost-effective |

| Inspection and QC | Needs advanced inspection, more time | Easier inspection, simpler quality control |

| Cost-Benefit Analysis | Higher initial cost, but better durability and longer life | Lower initial cost, best for budget and high-volume projects |

💡 Tip: If you want to save money on large batches, use chamfers for outside edges. If you need your part to last longer or handle more stress, fillets may cost more at first but save you money over time.

You should always match your choice to your project needs and budget. Think about how many parts you need, how strong they must be, and how much you can spend. This helps you make the best decision for your design.

Fillets vs. Chamfers: Performance

Load Bearing

Fillets and chamfers work differently when parts hold weight. Fillets make corners round and smooth. This shape spreads out force and lowers stress. Parts with fillets are stronger and less likely to crack. Fillets can help stiff shells hold up to 14% more weight. Engineers use fillets so parts last longer under heavy loads. Rounded corners also stop sudden breaks from repeated force.

Chamfers cut off sharp edges at an angle. Small chamfers help stop cracks from starting. This makes parts stronger, especially in hard metals like aluminum 7075-T6. If a chamfer is too big, it removes too much material and weakens the part. The best chamfer size depends on the material and how the force moves. For important parts, engineers check chamfers with stress tests.

| Feature | Fillet (Rounded Corners) | Chamfer (Angled Edges) |

|---|---|---|

| Stress Relief | Excellent, spreads force evenly | Good if small, but weakens if too large |

| Load Capacity | Higher, improves buckling resistance | Lower if chamfer removes too much material |

| Fatigue Life | Longer, resists cracks and breaks | Better than sharp edges, but less than fillet |

Tip: Use fillets for parts that carry heavy loads or face repeated stress. Pick chamfers for easier assembly and medium strength.

Durability

Durability means parts last longer and do not break easily. Fillets help by lowering stress at corners. Rounded corners stop cracks and peeling. This makes joints stronger and helps parts work better in tough places. Fillets also make glue bonds tougher and help parts last longer under pulling force.

Chamfers also help parts last longer by cutting off sharp edges. This stops chipping and makes assembly easier. Chamfered edges help parts fit together without damage. If a chamfer is too big, the part can get weak. You need to pick the right chamfer size for strength and durability.

- Fillet:

- Lowers stress at corners.

- Makes joints stronger.

- Helps parts last longer in hard use.

- Chamfer:

- Cuts off sharp edges.

- Stops chipping.

- Needs the right size for the best strength.

Note: Fillets give the best durability in high-stress spots. Chamfers are good for easy assembly and normal wear.

Safety

Safety is important in every design. Fillets take away sharp corners and make smooth, round edges. This lowers the chance of injury when people touch the parts. Rounded corners feel nice and make products safer to use often. Fillets also spread out stress, stopping cracks and sudden breaks. You see fillets in handles and plastic parts where safety matters most.

Chamfers also make parts safer. They remove burrs and sharp edges that can cut or scratch during assembly. Chamfered edges make it safer to handle parts and speed up assembly. You see chamfers in gears and airplane parts where smooth assembly is needed. If you use chamfers, check that the edge is not too sharp. Sometimes, you need to add a fillet to the chamfer for extra safety.

- Fillet:

- Takes away sharp corners.

- Makes parts safer to touch.

- Feels better and is easier to use.

- Chamfer:

- Removes burrs and sharp edges.

- Lowers injury risk during assembly.

- Needs careful checking for sharpness.

💡 Safety tip: Use fillets for products people touch a lot. Use chamfers for safer assembly and easier handling.

Manufacturing Impact

Machining

Machining plays a big role in how you add fillets and chamfers to your parts. In engineering, you use CNC machines to create fillets with smooth, rounded edges. You need special tools like ball nose end mills and corner rounding end mills for this job. These tools help you control the fillet radius and make sure your part meets design needs.

Fillets help your metal parts last longer by spreading out stress and stopping cracks. When you want to add a chamfer, you use standard end mills or chamfer tools. These tools cut angled edges quickly and work well for most materials. Chamfers make assembly easier and help parts fit together. You can machine a chamfer faster than a fillet, especially if you use manual methods.

In engineering, CNC machining lets you switch between fillets and chamfers with tool changes, but fillets often take more time because of their curved shape.

Tip: Use CNC machines for precise fillets and quick chamfers. Pick the right tool for each edge to get the best results.

Tooling

Tooling affects how you make fillets and chamfers in your engineering projects. You need special forming tools for fillets, which can cost more and take longer to set up. Ball nose end mills and corner rounding tools help you create smooth fillet radii. These tools work best for inner corners and rounded transitions. For chamfers, you can use ordinary turning tools on a lathe or standard chamfer tools on a CNC machine. Chamfers are easier and cheaper to machine because you do not need special tools.

You get higher processing efficiency with chamfers, especially on CNC machines. If you design inner cavities with chamfers or right angles, you may need extra processes like electrical-discharge machining, which adds cost. The choice between fillet and chamfer changes the type of tooling, the complexity of your setup, and your overall manufacturing cost.

- Fillets need special forming tools and careful planning.

- Chamfers use standard tools and offer faster setup.

- Inner corners with fillets are easier to machine than chamfers.

- Extra processes for chamfers can increase cost in complex designs.

Time and Cost

Time and cost matter in every engineering project. Chamfers usually take less machining time than fillets. You can cut a chamfer quickly with a single pass, which saves you time and money. Fillets need more passes and careful control of the radius, so they take longer to machine.

When you use CNC machines, the time difference between fillets and chamfers is smaller, but tool changes can slow you down. Both fillets and chamfers can increase CNC machining costs if you use them too much or pick the wrong size.

Fillets help reduce tool wear and improve surface finish, which lowers the need for extra finishing steps. Chamfers help with fast assembly and chip removal, making your process more efficient. If you balance the size and number of fillets and chamfers, you can keep your costs low and your parts strong.

| Feature | Chamfer | Fillet |

|---|---|---|

| Machining Time | Generally faster | Typically takes longer |

Note: Use chamfers for quick production and lower costs. Add fillets where you need strength and durability, even if it takes more time.

Use Cases

Fillet Applications

Fillet features are used in many engineering designs. Fillet edges make parts safer and stronger. They also help parts look nicer. When you add fillet shapes to inside corners, stress spreads out. This helps stop cracks from forming. Rounded corners from fillet cuts lower the chance of injury. They also make products easier to hold. Fillet details help your design last longer and look better.

- In cars, fillet edges are used in engine parts like pistons and crankshafts. Fillet shapes help these parts handle heavy loads. They also lower the risk of breaking.

- In airplanes, engineers add fillet curves to wings and shuttle parts. Fillet transitions help air move better and lower stress at sharp corners.

- In electronics, fillet edges make smooth surfaces. Rounded corners make phones and laptops feel better in your hand. They also look more modern.

- In buildings and bridges, fillet features help resist wind and other forces. Fillet curves also help coatings stick, which stops rust.

- Fillet edges are best when you need to spread weight over a bigger area. This helps avoid bending and makes your product last longer.

- You pick fillet shapes when safety and looks are important. Fillet details take away sharp edges and give a soft, finished look.

Tip: Use fillet features for parts under high pressure or that need smooth movement. Rounded corners from fillet cuts help prevent injuries and make products last longer.

Chamfer Applications

Chamfer features help you put parts together fast and save money. You use chamfer edges to guide screws, pins, and bolts. Chamfer cuts make it easier to fit parts together. They also help stop mistakes during assembly. You pick chamfer shapes for a sharp, modern look.

- In gears and machines, chamfered edges help line up parts. Chamfer cuts make assembly faster.

- In welding, chamfer shapes make V-shaped joints. Chamfer details give more space for weld material and make joints stronger.

- In electronics, chamfer edges give a sharp, geometric style. Chamfer cuts make devices look sleek and modern.

- For big production runs, chamfer features are easier and cheaper to make. You use standard tools and fewer steps.

- Chamfer shapes work well when you need to remove sharp edges fast. You save time and money, especially on outside edges.

- You use chamfer cuts when cost and speed are more important than stress relief. Chamfer features help you finish parts quickly and keep costs low.

Note: Pick chamfer edges for parts that need quick assembly and easy alignment. Chamfer shapes are best when you want to save time and money and get a modern look.

Selection Criteria

Material

The material you pick is important when choosing a fillet or a chamfer. Different materials act in their own way under force. Strong metals and brittle plastics can crack if not designed correctly. Fillets help lower stress in these parts. You see fillets a lot in parts that might break easily. Fillets spread out force, so the part is stronger and less likely to fail. If your material is soft, you can use bigger fillets. Harder materials need smaller fillets because they are tough to cut.

- Fillets are best for:

- Metals that hold heavy loads

- Plastics that might crack at sharp corners

- Parts that need to last a long time

- Chamfers are good when:

- You want parts to fit together easily

- The material is easy to cut

- You need to get rid of sharp edges fast

Remember: Always match the fillet size to your material’s strength and how it handles force.

Standards

You have to follow the rules when you add fillets or chamfers. These rules keep your parts safe and easy to make. Many industries, like cars and planes, have rules for the smallest fillet or chamfer you can use. These rules help stop weak spots and make sure parts fit together. If you skip these rules, your part might break or not pass checks.

- Check your industry’s rules before picking a fillet size.

- Use common tool sizes for fillets to save time and money.

- For chamfers, use angles like 45 degrees. This makes cutting easier and cheaper.

- Always show fillet and chamfer sizes clearly on your drawings.

Tip: Following rules helps you avoid mistakes and keeps your design safe and strong.

Design Needs

What your part needs will help you choose fillet or chamfer. If your part gets heavy loads or lots of use, fillets are best. Fillets lower stress at corners and help your part last longer. If you want your part to look smooth and feel nice, fillets give a soft look. For parts that need to go together fast, chamfers help guide pins and bolts. Chamfers also make it easy to get rid of sharp edges and make things safer.

| Design Factor | Fillet (Rounded Edge) | Chamfer (Angled Edge) |

|---|---|---|

| Stress Distribution | Great for lowering stress, best for loaded parts | Okay, mostly for breaking sharp edges |

| Assembly | Not as good for guiding parts | Helps guide pins and bolts, makes assembly faster |

| Safety | Removes sharp corners, safer to touch | Quick edge breaking, makes handling safer |

| Aesthetics | Soft, smooth look | Technical, machine-like look |

| Manufacturing Cost | Can cost more, needs special tools | Costs less, uses normal tools |

When you plan your part, think about stress, looks, safety, and cost. Use fillets for strength and smooth edges. Use chamfers for quick assembly and saving money. Good planning helps you pick the best feature for your project.

Summary Table

When you need to choose between a fillet and a chamfer, you should look at all the important factors. Each feature has its own strengths and weaknesses. You want your design to work well, stay safe, and cost less. The table below helps you compare fillet and chamfer side by side. This makes it easier for you to pick the right option for your project.

| Factor | Fillet | Chamfer |

|---|---|---|

| Stress concentration | Low | High |

| Safety | Rounded edges, safer to handle | Sharp edges, less safe |

| Assembly | Harder to assemble | Easier to assemble |

| Cost | More expensive | Less expensive |

| Aesthetics | Smooth, rounded look | Angled, technical look |

| Machining efficiency | Slower, needs special tools | Faster, uses standard tools |

| Rust prevention | Better coating, less rust | Coating peels, more rust |

| Manufacturing difficulty | Harder to make | Easier to make |

| Hole fitting | Not as good | Better fit |

You can see that a fillet helps lower stress at corners. This makes your part stronger and less likely to break. You also get a safer edge that feels smooth when you touch it. A fillet works best for parts that need to last a long time or carry heavy loads. You should use a fillet if you want a nice, rounded look and better protection against rust. The curved shape helps paint and coatings stick better, so your part stays protected.

A chamfer gives you a sharp, angled edge. This makes assembly faster and easier. You save money because you do not need special tools. Chamfers work well for parts that need to fit together quickly. You get a modern, technical style with a chamfer. However, sharp edges can cause injuries, so you need to be careful when handling these parts. Coatings may peel off faster from chamfered edges, which can lead to rust over time.

Tip: If you want strength and safety, pick a fillet. If you need speed and lower cost, choose a chamfer.

You should always match your choice to your project needs. Think about how much stress your part will face, how it will be used, and how much you want to spend. Use the summary table to help you decide. This way, you can avoid mistakes and make your design better.

Decision Checklist

Choosing between a fillet and a chamfer can feel tricky. You want your project to work well, stay safe, and not cost too much. Use this checklist to help you make the right choice for your next design.

1. What is the main goal for your part?

- If you want to lower stress and make your part last longer, pick a fillet.

- If you want fast assembly and easy alignment, choose a chamfer.

2. Will your part carry heavy loads or face repeated force?

- Fillets help spread out the force and stop cracks.

- Chamfers work for lighter loads or parts that do not face much stress.

3. How important is safety?

- Fillets remove sharp corners and make parts safer to touch.

- Chamfers also remove sharp edges, but can still feel a bit sharp.

4. Do you need quick and easy assembly?

- Chamfers guide screws, pins, and bolts into place.

- Fillets help with smooth movement, but do not guide parts as well.

5. What does your design need to look like?

- Fillets give a soft, rounded look.

- Chamfers create a sharp, technical style.

6. What tools and machines do you have?

- Fillets need special tools and take more time to make.

- Chamfers use standard tools and are faster to machine.

7. What is your budget?

- Fillets may cost more at first, but can save money by making parts last longer.

- Chamfers cost less to make, which helps if you need many parts.

8. What material are you using?

- Fillets work best for metals and plastics that might crack.

- Chamfers are good for easy-to-cut materials and quick edge removal.

📝 Tip: Always check your industry standards before you finish your design. Some projects need a certain size for fillets or chamfers.

Quick Reference Table

| Question | Fillet | Chamfer |

|---|---|---|

| Lower stress? | ✅ | ❌ |

| Fast assembly? | ❌ | ✅ |

| Safer to handle? | ✅ | ⚠️ |

| Cheaper to make? | ❌ | ✅ |

| Modern, technical look? | ❌ | ✅ |

| Needs special tools? | ✅ | ❌ |

Use this checklist every time you start a new design. You will avoid common mistakes and make better choices for your project.

When you choose between a fillet and a chamfer, always think about the part’s purpose, the material, and how you will make it. Many engineers make mistakes by mixing up fillets and chamfers or picking the wrong size. To avoid this, use the summary table and checklist. Match each feature to your project’s needs. This helps you save money, build safer parts, and make your designs last longer. Following these steps will improve your work’s efficiency and durability.

FAQ

A fillet gives you a rounded edge. A chamfer gives you a flat, angled edge. Fillets help lower stress and improve safety. Chamfers make assembly easier and cost less to machine.

You should use a fillet when your part needs to handle heavy loads or repeated stress. Fillets help prevent cracks and make your part last longer. They also make edges safer to touch.

Yes, you can use both. You might add fillets to inside corners for strength and chamfers to outside edges for easy assembly. This approach gives you the benefits of both features.

Fillets usually cost more to machine because they need special tools and take more time. Chamfers use standard tools and finish faster. For large batches, chamfers save you more money.

Check your industry standards first. Use the largest fillet that fits your design for better strength. For chamfers, pick a common angle like 45°. Always show the size clearly on your drawings.

A small chamfer removes sharp edges without much loss of strength. A large chamfer can weaken your part by removing too much material. Always balance size with your strength needs.

Fillets work better for 3D printing. They help reduce stress and improve part strength. Chamfers print easily but may not give you the same durability as fillets.

Tip: Always match your choice to your project’s needs and check your design before you start manufacturing.