Powder Metallurgy

Choose a powder metallurgy solution from AFI Industrial Co., Ltd. to differentiate your products in a competitive market for higher performance and longer service life.

Custom Powder Metallurgy

AFI Industrial Co., Ltd. produces various powder metallurgy products for customers. We are equipped with over 100 sets of automated forming and finishing equipment, including mesh belt sintering furnaces, vacuum sintering furnaces, and multiple sets of mold processing equipment. With these devices and technologies, we can customize and produce various powder metallurgy structural components, high-precision gears and precision oil-impregnated bearings for our customers. These products are widely used in industries such as automobiles, motorcycles, home appliances, power tools, office equipment and locks. Both in terms of quality and quantity, they can meet the demands of customers.

Powder Metallurgy Shop

The workshop adopts an intelligent control system and is capable of producing powder metallurgy parts with various complex structures.

Pressed and Sintered

Metal powder is pressed into shape and then sintered at high temperatures to turn the powder into strong and durable metal parts.

Components

Powder metallurgy mass production speed, stable quality, and high precision can meet the various needs of customers.

Measurement

Precise inspection equipment and professional personnel ensure that customers get high-quality products.

Custom Powder Metallurgy Service

AFI Industrial Co., Ltd. provides customers with high-quality powder metallurgy product services. We are equipped with fully automatic forming machines, finishing equipment, mesh belt sintering furnaces, vacuum sintering furnaces and precision mold processing centers, which can ensure that every link from raw materials to finished products meets strict quality standards. We can produce powder metallurgy parts made of various materials such as iron-based, copper-based and stainless steel for our customers, which are widely used in industries like automobiles, home appliances and power tools. Whether it is small-batch customization or large-batch production, we can provide customers with various technical support and supporting services, closely cooperating with customer needs throughout the process to enable customers to receive high-quality products quickly.

Precision Powder Metallurgy

AFI Industrial Co., Ltd. specializes in the manufacturing of powder metallurgy parts. It adopts metal powder pressing and high-temperature sintering processes. The dimensional accuracy of its products is controlled within ±0.03mm, and the density reaches over 95%.

These parts are applied in automotive engine components, transmission gears of household appliances, motor parts of power tools and other occasions. They have high strength and wear resistance. Through strict quality control, we ensure that each batch of products has stable and reliable performance and meets the requirements of various industries. Support from sample trial production to mass production, providing customers with cost-effective powder metallurgy solutions.

Powder Metallurgy Sample Development

AFI Industrial Co., Ltd. provides sample development services for powder metallurgy. Perfect for designers and engineers, our prototyping capabilities allow you to quickly test and improve your designs, helping you get ahead in the market by releasing new products in the shortest possible time.

Custom Precision Powder Metallurgy Service

Customized precision powder metallurgy parts are key components crafted to meet specific customer needs.AFI Industrial Co., Ltd. uses advanced production technology to press various shapes of parts using differently shaped molds with high precision and low material waste to meet the stringent requirements of complex projects, to provide reliable support for various types of equipment, to improve overall performance, and to meet customer demands for quality demand of products.

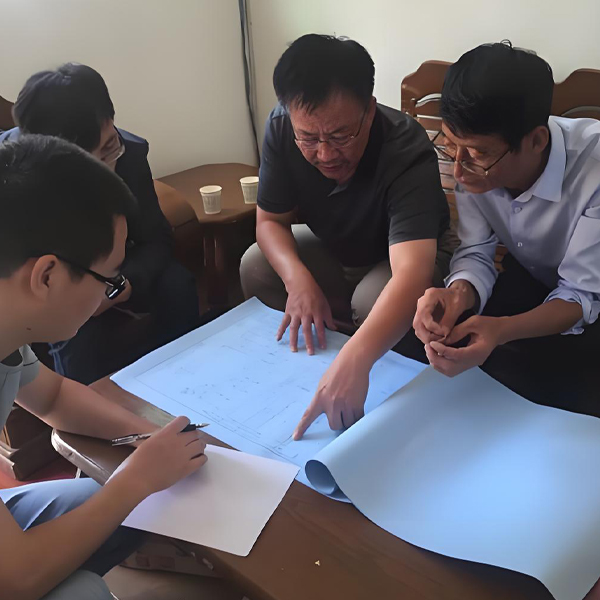

Drawings

After receiving the customer’s drawings, our technical team will conduct a drawing review and process planning to ensure that each processing link meets the requirements of the drawings, and the product size accuracy is controlled within ±0.01mm. Our quality control system ensures that the mass-produced products are consistent with the samples and meet all the technical requirements of customers.

Engineer Analysis Drawing

The engineering team carried out three-dimensional tolerance analysis based on the GD&T standard. They selected the base material in combination with the ASTM material database, optimized the technical parameters through CAM programming, and simultaneously formulated the three-coordinate inspection procedures to ensure the control of μ-level form and position tolerances.

Metal Forming

Our technical team, relying on years of processing experience, strictly adheres to standardized process flows and uses intelligent numerical control systems to precisely control processing parameters, ensuring that each product meets the dimensional accuracy and surface finish requirements of the drawings, providing customers with stable and reliable precision parts processing services.

Metal Product Measurement

From mold manufacturing to forming to sintering and shaping, quality inspectors inspect the products according to the drawings to ensure that the products fully meet the customer’s quality requirements.

Powder Metallurgy Materials

AFI Industrial Ltd. offers a variety of customized powder metallurgy materials. Including metals, alloys, ceramics, etc. Some of these materials have high strength, high hardness, and high wear resistance, and some have good magnetic and high electrical conductivity. It can produce parts with complex shapes that are difficult to make by traditional casting or machining methods. These materials have a wide range of applications in automotive, aerospace, electronic machinery, and other industries.

Iron-based powder metallurgy materials are the most widely used type in our powder metallurgy. The iron-based powder metallurgy products produced by our company have a material utilization rate as high as 98%, with tensile strength easily exceeding 800MPa and high mechanical properties. In addition, we can also apply it in the fields of power tools, automobiles, smart homes, and aerospace, which can effectively help you reduce production costs and enhance market competitiveness.

- Pure iron powder

- Mild steel powder

- High carbon steel powder

- Stainless steel powder

- Tool steel powder

The hardness of copper-based powder metallurgy materials is typically between HRF20 and 70, with tensile strength greater than 20MPa and compressive strength ≥80MPa. It inherits copper’s high electrical and thermal conductivity, as well as its wear resistance and corrosion resistance. By adjusting the powder composition and sintering process, we can produce products that meet the specific needs of our customers. These products are widely used in fields such as electronics and electrical appliances, automobiles, aerospace, etc.

- Pure copper powder

- Bronze powder

- Brass powder

- White copper powder

The density of aluminum-based powder metallurgy materials is relatively low, generally ranging from 2.5 to 2.9 grams per cubic centimeter, but their strength is very high. It not only retains the excellent electrical and thermal conductivity of aluminium itself, but also has the characteristics of wear resistance and corrosion resistance. Through powder metallurgy processes, we can precisely control the composition and microstructure of materials, thereby customizing aluminum-based powder metallurgy products that meet specific performance requirements for customers.

- Pure aluminum powder

- Aluminium alloy powder

Nickel-based powder metallurgy materials have outstanding high-temperature strength, good corrosion resistance, and stable physical properties, showing significant advantages in the field of powder metallurgy. They are widely used in the aerospace, automotive, chemical, and energy industries.

- Pure nickel powder

- Nickel alloy powder

Titanium-based powder metallurgy materials have excellent specific strength, good corrosion resistance, and high-temperature resistance, are lightweight, and are widely used in aerospace, automotive, and other high-performance applications.

- Pure titanium powder

- Titanium alloy powder

Tungston-based powder metallurgy materials have outstanding performance. Their density can reach 15-18 grams per cubic centimeter, approaching 19.3 grams per cubic centimeter of pure tungsten. Their hardness is between HRA 80 and 90, and their tensile strength is as high as 800-1200 megapascals. This material is particularly heat-resistant, with a melting point exceeding 3,400 degrees Celsius. Moreover, its coefficient of thermal expansion is very low, only 4.5×10⁻⁶ per degree Celsius, and it can remain stable even at high temperatures.

The materials of this type produced by our company have been applied in multiple fields, such as aerospace, electronic manufacturing and medical device industries. We can customize tungsten-based powder metallurgy products of different specifications according to the specific needs of customers to meet the requirements of various harsh usage environments.

- Pure tungsten gold powder

- tungsten alloy powder

Molybdenum-based powder metallurgy materials have high melting points, high density, high thermal conductivity, low thermal expansion coefficient, and good high-temperature strength, and are widely used in aerospace, nuclear energy, electronics, and metallurgy.

- Pure molybdenum powder

- Molybdenum alloy powder

cemented carbide powder metallurgy materials are particularly hard, highly wear-resistant and have high strength. Powder metallurgy products made of this material are widely used in industries such as mechanical processing, mining, aerospace, etc. We can provide customized cemented carbide solutions based on the different working conditions and requirements of our customers..

- WC

- TiC

- TaC

- NbC

The advantages of magnetic materials in powder metallurgy include the ability to produce single crystal or single domain size particles of various magnetic materials

By forming under the magnetic field and other processes to make highly magnetic magnets, the powder metallurgy process can also compound magnetic powder with other substances to make materials with specific properties. Magnetic materials are widely used in industrial automation, electronic and information technology, and new energy fields.

- Rare earth permanent magnet materials (such as Ndfeb, Samarium cobalt)

- Soft magnetic material

Ceramic powder metallurgy materials have a hardness second only to diamond, and their wear resistance is 5 to 8 times that of ordinary steel. They can still maintain stable performance at a high temperature of 1600℃. Ceramic powder metallurgy products are widely used in mechanical manufacturing, metallurgy, chemical engineering, new energy and other fields. Our company can provide customers with customized ceramic powder materials of different specifications according to the specific working conditions and requirements.

- Al2O3

- SiC

- Si3N4

- B4C

The high temperature alloy powder metallurgy can reach over 1000℃, which is 2 to 3 times that of traditional cast alloys. Its grains are fine and uniform (usually 10-50μm), the porosity is less than 0.5%, and the tensile strength at room temperature is over 1500MPa. High-temperature alloy metallurgical products are widely used in aerospace, energy and power, petrochemicals, automotive industries and other fields. Our company can provide customers with customized high-temperature alloy solutions based on the specific usage requirements of the products.

- iron base superalloy

- nickel-base superalloy

- cobalt-based superalloy

Custom Powder Metallurgy Surface Treatment

To improve the performance and service life of materials, AFI Industrial Ltd. provides surface treatment services for powder metallurgy products. Common surface treatments include electroplating, spraying, heat treatment, and chemical treatment.

Coating a layer of electroplating on the surface of products can improve its corrosion resistance and mechanical strength. Commonly used electroplating materials include chromium plating, nickel plating, zinc plating, etc.

Due to the porosity of powder metallurgy parts, direct plating may lead to poor surface quality, so it is necessary to seal the hole first.

Engineers spray specific coating materials on the surface of products, which can enhance the corrosion resistance and service life of the products. Common coating methods include thermal spraying, cold spraying, high-temperature spraying, etc. We can customize the spraying method for customers according to their specific needs to meet their particular quality requirements.

Powder metallurgy products can enhance their hardness, strength, mechanical properties, etc. through heat treatment processes. The commonly used heat treatment methods in our company include quenching, tempering, etc. According to the nature of the product, we can customize the appropriate heat treatment method for customers to meet their quality requirements for the product.

Powder metallurgy products can enhance their surface properties, such as hardness, wear resistance, and fatigue resistance, through chemical heat treatment processes. It is applicable to a variety of metal materials and parts. The commonly used types of chemical heat treatment in our company include carburizing, nitriding and metal carburizing, etc. Engineers can select different infiltration elements and process parameters according to customer demands to meet the quality requirements of customers for the products.

Sandblasting is a process for surface treatment of workpieces. The compressed air is used as the power to form a high-speed jet beam to spray the spray material (copper ore, quartz sand, emery, iron sand, sea sand) to the surface of the workpiece to be treated at high speed so that the appearance or shape of the workpiece surface is changed.

Polishing refers to the use of mechanical, chemical or electrochemical action to reduce the surface roughness of the workpiece in order to obtain a bright, flat surface processing method. Is the use of polishing tools and abrasive particles or other polishing media to modify the surface of the workpiece.

Mass Production

AFI Industrial Co., Ltd. has a variety of specifications of automatic forming and finishing equipment more than 100 sets, mesh belt sintering equipment and vacuum sintering equipment, mold manufacturing and processing equipment, can customize a large number of powder metallurgy parts of the same quality, our business personnel will fully understand the customer’s product time requirements, and effectively arrange the production schedule, to ensure timely delivery. Working with us, you’ll get reliable products, quality service, and efficient production solutions to help your business thrive.

How to Start Your Order

Send your drawings

Process discussion, quotation

Make a sample

Volume produce

Shipment & Payment

Shipping

Checkout

AFI Industrial Co., Ltd. has established a quality management system for CNC parts, equipped with professional testing equipment and a senior quality inspection team. We conduct all-around inspections at every stage in accordance with the customer’s drawings and technical standards to ensure that all products meet 100% of the customer’s quality requirements and industry standards.

Shipment

AFI Industrial Co., Ltd. collaborates with many well-known logistics partners worldwide. We will carefully package your products based on their characteristics and requirements, and then select the most cost-effective and fastest transportation plan for you to ensure the safe and punctual delivery of your goods.

Our Promise

With our services, you will get a trusted supplier. In the coming days, we will continue to improve our professional degree, expand our credibility, and let you get the following harvest!

Quality Guarantee

We provide a full range of checks to ensure that the dimensions are accurate and the appearance meets customer specifications during the powder metallurgy.

Quick Response

After receiving the order, we respond quickly within 2 hours, quote within 4 hours, and deliver according to quantity within 3-15 days.

Custom Material

We will according to the needs of customers, carefully select high-quality raw materials, customized to meet customer needs for all kinds of products.

Custom Surface Treatment

We can apply a variety of surface treatments to manufactured products according to customer requirements, including electroplating, anodizing, etc.

Arbitrary Size

We can produce products strictly in accordance with the dimensions on the drawings provided by customers, ensuring that every dimension is precise and error-free, fully meeting the quality standards.

Unlimited Quantity

Whether you need samples or mass production, we can precisely manufacture according to your requirements, ensuring that the quality of each product remains consistent.

Brand We Cooperated with

AFI Industrial Co., Ltd. has specialized in precision parts processing for 15 years and possesses multiple high-precision five-axis turning centers. We have passed the ISO9001 quality system certification. We have long been providing key components for the automotive and home appliance industries. We have rich mass production experience in products such as transmission valve bodies and heat dissipation components. Our product quality is stable and reliable, with a defect rate controlled below 0.05%.

Frequent Asked Questions

Powder metallurgy can replace most complex-shaped and mass-produced parts, such as gears and bearings. Its advantages lie in saving materials (close to zero waste), requiring less processing (direct molding), and its cost is usually 30% to 50% lower than that of machining. It is especially suitable for orders with an annual output of over 10,000 pieces.

Powder metallurgy is a technology that involves pressing and sintering metal powders to form complex-shaped and high-precision parts. It is used in the automotive, electronic and mechanical industries.

Its main steps include powder preparation → mixing → pressing and forming → sintering → post-treatment (such as finishing, heat treatment), and some products also require oil immersion or surface coating.

Post-treatment methods for powder metallurgy include oil immersion lubrication, heat treatment strengthening, surface anti-corrosion and finishing processing. They can be used alone or in combination to enhance performance.