Sheet metal fabrication changes flat metal sheets into useful things. It does this by cutting, bending, forming, and putting pieces together. This method is important for making things we use every day. It helps make cars and home appliances. Sheet metal fabrication uses many different materials. The table below lists some common ones. These are used in construction, engineering, and electronics:

| Material Category | Description / Examples |

|---|---|

| Stainless Steel | Does not attract magnets, resists rust, looks nice, can be made harder |

| Cold Rolled Steel | Has a smooth surface, can be shaped very exactly |

| Pre-Plated Steel | Has a zinc layer to stop rust, bends easily |

| Aluminum | Comes in many types for strength, resists rust, easy to work with |

| Copper/Brass | Good for welding, makes a layer that protects it |

| Various Steels | Has low, medium, or high carbon for different strengths |

Sheet metal fabrication is the basis for metal work in many areas.

Key Takeaways

- Sheet metal fabrication changes flat metal sheets into useful things. These products are strong and light. Workers cut, bend, and join the metal to make them.

- Steel, aluminum, copper, and brass are common materials. People pick them for their strength and weight. They also look at corrosion resistance and cost.

- Modern tools help make fabrication fast and exact. CNC machines, laser cutters, and press brakes do this work. These tools also help save money.

- CAD software helps with design and planning. It stops mistakes and makes sure parts fit well. This helps parts work as they should.

- There are different ways to cut metal. Shearing makes straight cuts. Laser cutting is good for detail. Plasma cutting works for thick metals. Waterjet cutting is best for heat-sensitive materials.

- Bending and forming make 3D shapes from metal sheets. V-bending and roll bending are two methods. Each method works for different parts.

- Joining puts parts together in a strong way. Welding, riveting, or fasteners are used. Design features can add strength and make assembly easier.

- Finishing protects metal parts and makes them look better. Powder coating, painting, and anodizing are common finishing steps. These help metal last longer.

Table of Contents

Overview of Sheet Metal Fabrication

What is Sheet Metal Fabrication

Sheet metal fabrication means changing flat metal sheets into different things. The metal sheets are thin and flat. For steel, they are thinner than 3/16 inch. For aluminum, they are thinner than 1/4 inch. This process uses these sheets as the main material. Workers cut, bend, and join the sheets to make useful products. The main idea is to start with a flat sheet and shape it by forming. This method is special because it makes custom parts for many jobs. Other methods use blocks or rods, but this one always starts with a flat sheet.

| Core Concept | Description |

|---|---|

| Raw Material | Sheet metal: flat, thin, malleable metal sheets (e.g., aluminum, steel, copper) |

| Fabrication Processes | Cutting, bending, welding, punching, stamping |

| Tools and Machinery | Welders, CNC machines, shears, press brakes |

| Nature of Process | Manipulates flat sheet metal to create complex, customized, precise products |

| Product Characteristics | Versatile, durable, cost-effective, sustainable, high precision and customization |

| Industry Applications | Automotive, construction, electronics, aerospace, and more |

| Technological Integration | Use of CNC machining, laser cutting, automation, smart manufacturing |

| Design Flexibility | High level of customization and ability to produce intricate designs |

| Distinction from Others | Focuses on sheet metal as base, not bulk or other forms |

Key Features

Sheet metal forming has many good points for making things. It changes the shape of metal sheets without taking away much material. Workers use steps like bending, stamping, and rolling. These steps make parts that are strong and light. Sheet metal forming is very exact and can be done the same way every time. Modern machines like CNC cutters and press brakes help with this. The process works with many metals, like steel, aluminum, and copper. This makes it useful for many needs.

Some important features are:

- Versatility: It can make simple or hard shapes.

- Speed and efficiency: Machines help make things fast and cheaply.

- Material conservation: Most of the sheet gets used, so there is little waste.

- Strength: The parts stay strong but are not heavy.

- Corrosion resistance: Many metals do not rust or wear out fast.

- Precision: CNC machines help make parts very exact.

- Customization: You can make special shapes and sizes.

- Surface finishing: Workers can add coatings or polish to make things look better and last longer.

| Feature/Aspect | Description/Methodology | Importance in Sheet Metal Fabrication |

|---|---|---|

| Forming Features Extraction | Identified via 3-D component graphs and subgraphs using vector normal method and vertex fusion methodology. | Enables geometric and topological characterization of sheet metal parts for manufacturing and inspection. |

| Plane Identification | Various planes and their adjacency relationships are determined within the component graph. | Helps in understanding the part geometry and supports feature recognition and process planning. |

| Cross Bend Features | Extracted by identifying common edges between planes. | Critical for accurate bend allowance calculation and flat pattern development. |

| Shearing Features Recognition | Identified as part of the forming features. | Important for defining cutting operations in manufacturing. |

| Flat Pattern Development | Unfolding or unrolling 3-D surfaces onto a plane to create 2-D layouts. | Essential for nesting, material utilization, and process planning. |

| Use of Graph Theory & Pattern Recognition | Application of isomorphism principles to classify and extract features automatically from CAD models. | Facilitates automatic transformation of design data into manufacturing information, improving integration and efficiency. |

| Manufacturing Integration | Recognized features support Computer Aided Process Planning (CAPP), tool mapping, and inspection. | Ensures seamless transition from design to manufacturing, enhancing productivity and accuracy. |

Tip: Sheet metal forming uses special software and machines. These help plan and control each step. This makes the work more exact and faster.

Common Uses

Sheet metal forming is used in many things people see every day. It helps make car bodies, airplane parts, and ship hulls. In building, workers use it for roofs, walls, and air ducts. It also shapes parts for fridges and washing machines. Cabinets, shelves, and machine parts are made this way, too. Many electronic devices and medical tools use sheet metal forming for their cases and frames.

- Automotive: It shapes the outside and parts of cars, trucks, and buses.

- Aerospace: Airplanes and spacecraft use it for light, strong parts.

- Shipbuilding: Steel and brass are formed for hulls and fittings.

- Construction: It makes roofs, wall covers, and building signs.

- HVAC: Ducts and vents are made of steel and aluminum, formed this way.

- Appliances: It makes the shells and parts of home appliances.

- Storage: Cabinets, shelves, and lockers are strong and last long.

- Machinery: Many machine parts are made from sheet metal forming.

- Electronics: Cases and frames for computers and devices are used.

- Medical: Surgical tools and equipment often use stainless steel formed this way.

- Transportation: Cars, trains, and buses use it for hoods, roofs, and seats.

- Construction: It makes balconies, stairs, and support beams.

- Plumbing: Galvanized sheet metal makes strong pipes.

- Art and Decoration: It shapes playground equipment, sculptures, and home decor.

Sheet metal fabrication helps many industries, like farming, aerospace, electronics, and food service. It lets companies make products that are strong, light, and not too expensive.

Sheet Metal Fabrication Process

Design and Planning

Every sheet metal project starts with design and planning. Engineers and designers use CAD software to make drawings and 3D models. These files show the size, shape, and features of each part. Cloud-based CAD tools help teams work together and make changes fast. The software checks for mistakes and helps pick the right thickness, bend, and hole size. Flat layouts and gauge tables in CAD help make sure the design will work.

Key steps in design and planning are:

- Set the project goal and make a clear design.

- Check the shop’s tools and quality checks.

- Figure out all costs, like labor and finishing.

- Work with the team to fix problems early.

- Choose the best material for strength and finish.

Online services now let customers upload CAD files right away. The system checks the design, gives quick prices, and looks for problems. This makes the process faster and cuts down on mistakes. Users can upload 3D files like.STEP or.SLDPRT. The platform checks the design, suggests fixes, and helps plan the work.

Tip: Uploading CAD files online gives fast feedback. This helps stop costly mistakes before work starts.

Cutting

Cutting shapes the flat metal into the right size and form. There are many ways to cut, and each has its own use. Shearing uses a straight blade for quick, straight cuts. Laser cutting uses a strong beam for detailed shapes. Plasma cutting works well for thick metals that carry electricity. Waterjet cutting uses high-pressure water and sand to cut without heat. This is good for metals that can’t take heat. Saw cutting and chiseling are used for special jobs.

| Cutting Technique | Description | Best Use |

|---|---|---|

| Shearing | Straight blade for fast, straight cuts | High-volume, straight lines |

| Laser Cutting | Focused laser for detailed shapes | Thin metals, complex parts |

| Plasma Cutting | Ionized gas jet for thick metals | Steel, aluminum |

| Waterjet Cutting | High-pressure water with abrasives | Heat-sensitive, thick materials |

| Saw Cutting | Mechanical saws for simple cuts | Small shops, basic shapes |

Laser and waterjet cutting both give very exact cuts. Laser cutting is best for thin metals but can cause heat damage. Waterjet cutting does not use heat, so it is good for thick or soft metals. Many online services offer laser and waterjet cutting. This makes the work faster and more exact.

Bending and Sheet Metal Forming

Bending and forming turn flat sheets into 3D shapes. Press brakes, rollers, and special dies help bend the metal at the right angle. V-bending uses a V-shaped die for sharp bends. Roll bending makes curves and round shapes. Rotary bending and edge bending shape long edges or thick parts. Air bending and bottoming control the angle and stop springback. Wipe bending and coining make smooth or detailed bends.

| Forming Technique | Description | Common Use |

|---|---|---|

| V-Bending | V-shaped die for angles | Most common bends |

| Roll Bending | Rollers for curves | Pipes, tanks |

| Rotary Bending | Rotating punch for long bends | Heavy parts |

| Edge Bending | Bends only the edge | Roofing, trim |

| Air Bending | Partial press for flexible angles | Adjustable bends |

| Bottoming | Full press for accuracy | Precise angles |

Forming changes how strong and flexible the part is. Soft metals like aluminum and copper bend easily. The grain, thickness, and heat treatment also change how the metal bends. Good planning and the right method help stop cracks or warping.

Note: Online tools can check bend settings and suggest changes. This helps get better results.

Assembling

Assembling puts together all the metal parts to make one product. This step comes after cutting and shaping each piece. Each part is made ready to be joined with others. The goal is to make sure the final product is strong and fits well.

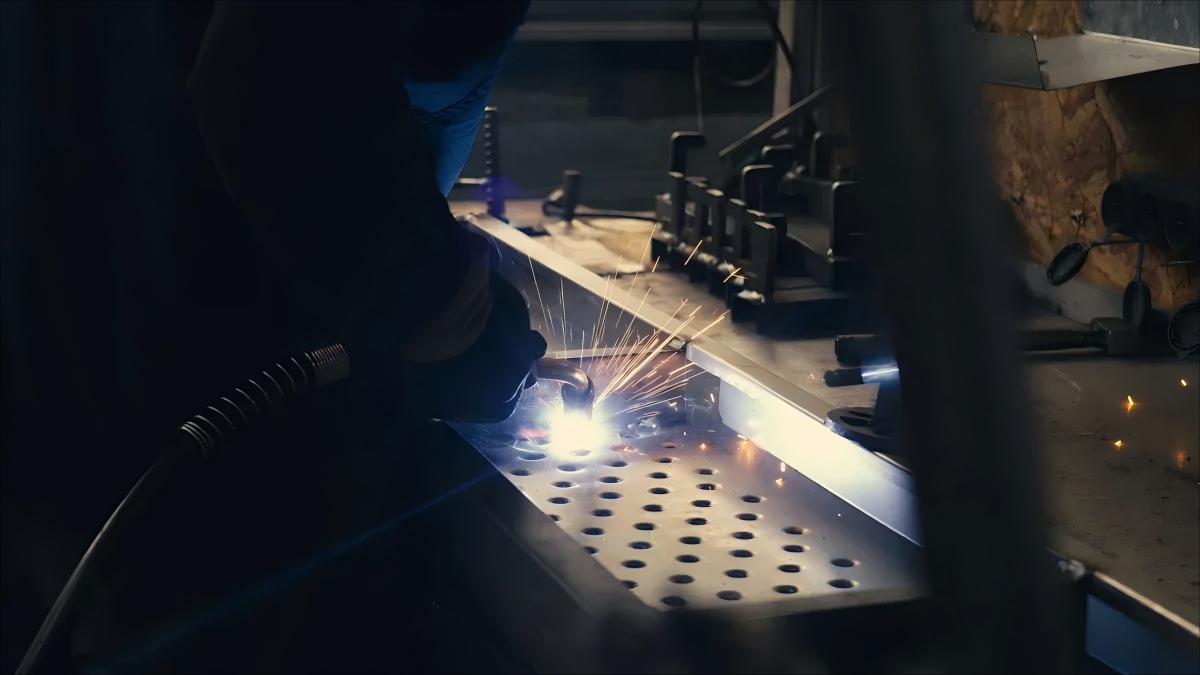

Many things need assembling to join different sheet metal parts. People or machines use welding, riveting, bolting, or hardware to connect them. Welding melts metal pieces together with heat. This makes a strong, lasting bond. Riveting uses metal pins to hold parts together. Bolting lets you take things apart later if needed. Screws and clips are also used to join pieces.

Designers try to use fewer parts to make assembly easier. This helps stop mistakes and saves time. Some parts can do more than one job. This makes building faster and cheaper. Using the same parts and fasteners keeps costs low. It also means workers do not need special tools. People or robots need enough space to use tools and put parts in place.

Poke-Yoke is a way to stop mistakes during assembly. Special shapes or connectors help put parts in the right spot. Quality checks happen before and after assembly. This makes sure every part is made right. Machines and robots help keep the joining steps exact every time.

How strong the product is depends on how it is joined and designed. Ribs, flanges, hems, and gussets make parts stronger. Ribs make things stiff. Flanges make edges tough. Hems make borders smooth and safe. Gussets help at corners and joints. Holes in the right spots can make things lighter but still strong.

| Assembly Technique / Feature | Description | Pros | Cons |

|---|---|---|---|

| Welding | Melts metal parts together | Very strong, smooth look | Needs skill, can bend parts |

| Riveting | Uses metal pins | No heat, works for many metals | Not as strong, needs both sides open |

| Bolting | Uses bolts and nuts | Can take apart later | Might get loose, needs exact holes |

| Hardware Integration | Uses screws, clips | Easy, can take apart | Needs hardware, needs exact holes |

| Ribs, Flanges, Hems, Gussets | Make parts stronger | Stops bending, keeps shape | Too many can cause stress |

Assembling in sheet metal forming uses smart design, careful joining, and checks for quality. This step makes sure the product is strong, safe, and ready for the next step.

Finishing

Finishing gives sheet metal products their final look and protects them. After assembly, finishing makes things look better and last longer. There are many ways to finish metal, and each has its own good points.

Powder coating and painting are two common ways to finish metal. Powder coating puts a tough, colorful layer on the metal. This stops rust and scratches. It is better for the earth and lasts longer than paint. Painting adds color and some protection, but it can scratch more easily.

Other ways to finish metal are brushing, polishing, and clear coating. Brushing makes the surface look dull and smooth. Polishing makes it shiny and bright. Clear coating adds a layer that stops rust and keeps the metal looking nice. Lacquering stops metal from turning color. Antiquing gives metal an old look. Electroplating and electroless plating add a thin metal layer for more shine and strength.

Some finishes work best for certain metals. Anodizing is great for aluminum. It makes a hard layer that stops rust and makes the surface tougher. Galvanizing covers steel with zinc to stop rust. Passivation takes away iron from stainless steel to help it resist rust.

Finishing keeps out water, chemicals, and dirt. This helps products last longer and look good. The finish you pick depends on the metal, where it will be used, and how you want it to look.

| Finishing Technique | Corrosion Resistance Impact | Notes |

|---|---|---|

| Powder Coating | Strong shield, stops rust and wear | Tough, looks nice, good for the earth |

| Painting | Basic shield, adds color | Scratches easily |

| Anodizing | Hard layer, great for aluminum | Makes surface tougher |

| Galvanizing | Zinc layer, stops rust well | Best for steel |

| Passivation | Takes away iron, helps stainless steel resist rust | Used for stainless steel |

| Electroplating | Adds metal layer, makes it stronger and shiny | Gold, silver, zinc can be used |

| Polishing | Smooth, shiny finish, helps welding | Often done before other finishes |

Finishing is the last step before people use the product. It makes sure each item looks good and can handle daily use and tough places.

Techniques in Metal Fabrication

Sheet metal forming uses many techniques to shape, cut, and join metal sheets. These methods help create strong, precise, and useful products for many industries. Understanding the main types of sheet metal forming helps people choose the right process for their needs.

Cutting Methods

Cutting changes flat metal sheets into the right size and shape. Each method has special features.

Shearing

Shearing uses a straight blade to cut metal sheets. This method works best for straight lines and simple shapes. Shearing is fast and cost-effective for high-volume jobs. It needs less skilled labor and has lower maintenance costs. However, it cannot make complex shapes and may leave rough edges.

Laser Cutting

Laser cutting uses a focused beam of light to melt or burn through metal. This method creates very precise cuts and can handle complex shapes. Laser cutting works well for thin materials and gives a clean finish. It needs skilled operators and has higher equipment costs, but it reduces waste and post-processing.

Plasma Cutting

Plasma cutting uses a jet of ionized gas to cut through metal. This method works well for thick and conductive metals like steel and aluminum. Plasma cutting is fast and can handle different thicknesses. It needs more energy and skilled workers, but it offers good speed and flexibility.

Waterjet Cutting

Waterjet cutting uses high-pressure water mixed with abrasives to slice metal. This method does not use heat, so it works well for metals that can warp or change with heat. Waterjet cutting can handle thick or soft metals and creates smooth edges. It is slower and more costly but gives high precision.

Note: Shearing is best for simple, straight cuts in large batches. Laser, plasma, and waterjet cutting work better for complex shapes and lower waste.

Sheet Metal Forming Techniques

Sheet metal forming changes flat sheets into 3D shapes. There are many types of sheet metal forming, each with its own use.

Bending

Bending metal sheets by pressing them into angles or curves. Press brakes and dies help control the angle and shape. Bending is fast, uses little energy, and creates strong parts. It works best for thin sheets and may have limits with thick or hard metals.

Stamping

Stamping presses a die into the metal sheet to make shapes, holes, or patterns. This forming method is fast and good for making many parts that look the same. Stamping works well for large runs but needs special tools, which can cost more.

Rolling

Rolling passes metal sheets through rollers to make them thinner or to create curves. This forming method is good for making pipes, tanks, and long shapes. Rolling works for many metals and thicknesses but needs expensive machines.

Deep Drawing

Deep drawing pulls a metal sheet into a die to make deep, hollow shapes like cans or sinks. This forming method creates smooth, strong parts with little waste. Deep drawing works best with flexible metals and may need special tools.

Tip: Sheet metal forming uses automation, CNC machines, and advanced materials to improve speed, safety, and quality.

Joining Methods

Joining connects metal parts to make a finished product. The right joining method depends on strength, look, and how the product will be used.

Welding

Welding melts metal parts together to form a strong joint. Types include MIG, TIG, spot, and laser welding. Welding creates joints as strong as the base metal. It works well for high-strength assemblies in cars and machines.

Riveting

Riveting uses metal pins to join sheets. This method does not use heat and works for many metals. Riveting is good for parts that need to stay together but may not be as strong as welding.

Fastening

Fastening uses bolts, screws, or clips to join metal sheets. This method allows parts to be taken apart if needed. Fastening is easy and quick, but may need exact holes and extra hardware.

| Joining Method | Strength | Best Use |

|---|---|---|

| Welding | Very strong | Cars, machines, strong frames |

| Riveting | Medium | Airplanes, metal panels |

| Fastening | Removable | Cabinets, electronics, repairs |

Sheet metal forming uses many joining methods to make sure products are strong, safe, and ready for use.

Materials for Sheet Metal Fabrication

Steel

Steel is the most used material in sheet metal work. It is strong, tough, and can bend without breaking. Many companies pick steel because it is easy to shape and connect. There are many kinds of steel, and each one is different.

Mild steel has little carbon. It bends and welds without much trouble. People use mild steel for frames, beams, and other basic parts. Stainless steel has chromium in it. This helps stop rust and stains. Stainless steel is tough and lasts a long time. It is used for kitchen tools, medical gear, and lab equipment. Galvanized steel is mild steel with a zinc layer. The zinc keeps it from rusting. Builders use galvanized steel for roofs and car parts.

Structural steel is made for building strong frames. It holds up heavy things and keeps buildings safe. Making structural steel means cutting, shaping, and joining beams and columns. Hot-rolled steel is another kind. It is bendy and strong. People use hot-rolled steel for car frames and wheels.

Tip: Steel is heavy but very strong. It can take hits and lots of weight. Many steel types can be used again, so they are good for the planet.

Here is a table that shows steel types and what they are used for:

| Steel Type | Description & Properties | Applications |

|---|---|---|

| Mild Steel | Low carbon, easy to weld, flexible, cost-effective | Beams, frames, industrial frameworks |

| Stainless Steel | High chromium, rust-resistant, durable, good for moisture exposure | Kitchen appliances, medical tools, equipment |

| Galvanized Steel | Zinc-coated, rust protection | Roofing, car components, exterior parts |

| Hot Rolled Steel | Flexible, tough, lower cost | Structural parts, automotive frames, wheels |

| Structural Steel | High strength, supports heavy loads | Building frameworks, bridges, towers |

Steel is still the best pick for many sheet metal jobs. Its strength and many types make it fit for lots of uses.

Aluminum

Aluminum is light and simple to shape. It does not rust because it forms a hard layer on top. Many companies use aluminum for things that must be light but strong. Aluminum bends and forms without breaking. It also moves heat well.

Aluminum is used for car parts, airplane pieces, and boat gear. It does not make sparks, so it is safe for some jobs. Aluminum can be used again, which saves resources. Some problems are that it is hard to weld and melts at low heat. Aluminum can get bigger when hot and scratches easily.

The table below shows what aluminum can do and where it is used:

| Material | Properties & Advantages | Disadvantages & Limitations | Common Applications |

|---|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, ductile, recyclable | Welding challenges, low melting point | Automotive, aircraft, marine equipment |

Aluminum is a smart pick for things that need to be light and not rust.

Copper and Brass

Copper and brass are special in sheet metal work. Copper moves electricity and heat very well. It also kills germs, so it is good for health. Copper makes a green layer over time that keeps it from rusting. People use copper for wires, heaters, and pretty things.

Brass is made from copper and zinc. It looks gold and is easy to shape. Brass does not rust and is used for fancy and building parts. Both copper and brass are soft and can scratch. They also cost more than steel or aluminum.

Here is a table that shows what copper can do and where it is used:

| Material | Properties & Advantages | Disadvantages & Limitations | Common Uses |

|---|---|---|---|

| Copper | Antimicrobial, conducts electricity and heat | Higher cost, soft, limited strength | Wiring, heat exchangers, decoration |

| Brass | Corrosion-resistant, easy to shape, gold color | Soft, scratches, higher cost | Decorative, architectural, plumbing |

Copper and brass are good for special sheet metal jobs. They are picked for electric, fancy, and health uses.

Material Selection Factors

Picking the best material is very important in sheet metal forming. The material you choose changes how the product looks, works, and costs. Engineers and designers think about many things before they decide. Each thing they look at changes the final result in its way.

The properties of a material matter a lot in sheet metal forming. Weight is important if the product needs to be light, like airplane parts. Aluminum is used for these because it is light and easy to shape. Steel is picked when something needs to be strong and last a long time. Stainless steel is good for things that should not rust and must look nice. Galvanized steel is chosen for things outside because it can handle rain.

Corrosion resistance is also important in sheet metal forming. Some metals, like stainless steel and aluminum, do not rust fast. This makes them good for things that go outside or get wet. Galvanized steel has a zinc layer that keeps it from rusting. Copper and brass also do not rust much, but they cost more and are softer.

Cost is a big thing to think about in sheet metal forming. Different metals have different prices. Steel is usually cheaper than stainless steel or copper. Aluminum costs more than steel but less than brass. The price also depends on how easy the metal is to work with. Harder metals need stronger machines and take more time, so they cost more. Thicker sheets are harder to cut and bend, so labor and machine costs go up.

How the product looks is important in sheet metal forming. Some jobs need a shiny or smooth finish. Stainless steel and polished aluminum look nice and last long. Brass gives a gold color to fancy things. Designers pick materials based on how they want the product to look after forming.

How easy it is to get the metal also matters in sheet metal forming. Some metals are easy to find, but others are rare or cost a lot. Steel is easy to get and comes in many types. Aluminum is common but can cost more in some places. Copper and brass are harder to find and are used for special things.

How the parts are put together helps decide which metal to use in sheet metal forming. Some metals are easier to weld or rivet. Steel is easy to weld and join. Aluminum can be hard to weld, but it works with other joining methods. Brass and copper are soft, so they need special care when forming and putting them together.

Sheet thickness is another thing to think about in sheet metal forming. Thick sheets are strong but hard to shape. Thin sheets are easy to bend and cut, but may not be strong enough. The properties of the metal help decide what thickness is best for the job.

The table below shows how different things change what material is picked in sheet metal forming:

| Factor | Impact on Sheet Metal Forming | Example Material Choices |

|---|---|---|

| Weight | Affects product mobility and ease of forming | Aluminum, steel |

| Corrosion Resistance | Extends product life, reduces maintenance | Stainless steel, galvanized steel |

| Cost | Determines project budget and forming complexity | Steel, aluminum, brass |

| Aesthetic Quality | Influences appearance after forming | Stainless steel, brass |

| Availability | Ensures timely sheet metal forming and delivery | Steel, aluminum |

| Assembly Process | Guides joining and forming methods | Steel, aluminum, copper |

| Sheet Thickness | Impacts strength and forming difficulty | Steel, aluminum |

Picking the right material for sheet metal forming means thinking about how it works, what it costs, and how it looks. Each job needs careful planning to match the material to the work. The best choice makes better products and saves money.

Tip: Always think about how the material will change forming, joining, and finishing in sheet metal forming. This helps stop problems and keeps costs low.

Equipment and Tools

Cutting Machines

Cutting machines are very important in sheet metal fabrication. They help turn flat metal sheets into the right shapes and sizes. Each machine cuts metal in its way. Some use heat, while others use sharp blades or strong force. There are many types of cutting machines. Plasma cutting tables use hot gas to cut metal fast. Laser cutters use a strong light beam for very exact shapes. Bandsaws have a blade with teeth that moves in a loop. This blade can cut straight or curved lines. Throatless shears let workers cut both straight and curved lines easily.

The table below shows some cutting machines and what they do:

| Machine Type | Description and Use |

|---|---|

| Plasma Cutting Table | Uses thermal energy for fast, thick metal cutting |

| Laser Cutter | Provides high precision for detailed shapes |

| Bandsaw | Cuts straight or curved lines with a toothed blade |

| Throatless Shear | Makes complex straight and curved cuts easily |

| Angle Grinder | Cuts, grinds, and polishes metal edges |

Cutting machines help workers get metal ready for the next steps. They make work faster and more accurately. This helps make better products.

Forming Machines

Forming machines change flat metal sheets into 3D shapes. These machines bend, stretch, or press the metal to make different parts. The press brake is the most common forming machine. It bends metal sheets by pressing them between a punch and a die. Other tools, like hand seamers and benders, help workers make small bends by hand. Folding tools help make neat folds in the metal. Stretchers and planishing hammers help make smooth curves and finish the surface.

Forming machines are used in many steps of fabrication. They help workers make strong and light parts for many jobs. The table below lists some forming machines and what they do:

| Forming Machine | Description and Use |

|---|---|

| Press Brake | Bends sheet metal into angles and shapes |

| Hand Seamer | Makes small, precise bends by hand |

| Bender/Folding Tool | Forms edges and folds in sheet metal |

| Stretcher | Forms smooth radius curves |

| Planishing Hammer | Smooths and finishes formed surfaces |

Forming machines help make both simple and hard parts. They make sure each part has the right shape and strength.

Tip: Picking the right forming machine makes products better and saves material.

Welding and Assembly Tools

Welding and assembly tools join metal parts together. Welding tools use heat to melt and stick metal pieces. Arc welders, MIG welders, TIG welders, and spot welders are common types. Each welder works best for certain metals and thicknesses. Welding makes strong joints that last a long time.

Assembly tools include rivet guns, bolts, screws, and fasteners. These tools join parts without heat. Workers use drills to make holes for fasteners. Marking tools like scribers and calipers help line up holes and joints. Personal protective equipment (PPE) like helmets, gloves, and safety glasses keeps workers safe.

The table below shows some welding and assembly tools:

| Tool Type | Description and Use |

|---|---|

| Arc Welder | Joins metal parts using electric current |

| MIG/TIG Welder | Provides precise welding for different metals |

| Rivet Gun | Fastens parts with metal pins |

| Drill | Makes holes for fasteners and assembly |

| PPE | Protects eyes, hands, and body during fabrication |

Welding and assembly tools help make products strong and safe. They are needed for every step in making metal parts.

Finishing Equipment

Finishing equipment gives sheet metal products their final look and protection. Workers use these machines to clean, smooth, and coat metal. Each tool does a special job in finishing.

What is Finishing Equipment?

Finishing equipment means machines and tools that change metal surfaces. These tools take away sharp edges and polish the metal. They also add layers to protect the metal. Workers use finishing equipment after cutting, shaping, and putting the metal together.

Types of Finishing Equipment

- Deburring Machines

Deburring machines take off rough edges and tiny bits left after cutting. They use brushes, belts, or tumblers. Workers use them to make edges safe and smooth. - Grinders and Sanders

Grinders and sanders make flat or curved surfaces smooth. They use rough wheels or belts. These tools get metal ready for painting or coating. - Polishing Machines

Polishing machines make metal shiny and bright. They use soft wheels and special creams. These machines help make stainless steel or aluminum look like a mirror. - Blasting Equipment

Blasting equipment cleans metal with sand or glass beads. Workers use sandblasters or bead blasters to take off rust, paint, or dirt. This step gets metal ready for coating. - Coating and Painting Systems

Coating systems spray paint or powder onto metal. Spray booths keep dust away and clean the air. Ovens bake powder coatings so they stick to the metal. - Anodizing and Plating Equipment

Anodizing machines put a hard layer on aluminum. Plating equipment covers metal with a thin layer of another metal, like zinc or chrome. These machines use electricity and special baths.

| Equipment Type | What It Does | Common Use |

|---|---|---|

| Deburring Machine | Takes off sharp edges | Safety, smooth finish |

| Grinder/Sander | Makes surfaces smooth | Gets ready for coating |

| Polishing Machine | Makes surfaces shiny | Decorative parts |

| Blasting Equipment | Cleans and roughens surfaces | Gets ready for painting |

| Coating System | Puts on paint or powder | Adds color, protects metal |

| Anodizing/Plating | Adds a hard or shiny layer | Aluminum, jewelry, hardware |

Tip: Workers choose finishing equipment based on the metal and the look they want.

Finishing equipment helps products last longer and look better. Each tool helps make sure sheet metal parts are safe, smooth, and ready to use.

Benefits and Applications

Advantages

Sheet metal fabrication has many good points for companies and designers. It helps save money and time. Machines like CNC cutters and lasers help workers make parts very exact. Sheet metal parts can be made fast, so companies finish work on time. The materials are easy to recycle, which is good for the earth. Sheet metal is strong and lasts a long time, so it is great for things that need to be tough.

The table below lists the main good points of sheet metal forming:

| Benefit | Explanation |

|---|---|

| Cost-Effective | Steel and aluminum sheets cost less than solid blocks; automated machines lower labor costs. |

| High Accuracy & Precision | CNC and CAD tools help workers make parts with tight tolerances. |

| Rapid Prototyping | Computer-controlled machines allow fast production of prototypes and small batches. |

| Short Lead Times | Full-service shops handle all steps, so products are ready faster. |

| Recyclable & Sustainable | Sheet metal parts can be recycled, which helps the environment. |

| High Strength | Metals like steel provide strong support for heavy loads and tough conditions. |

| Malleable | Easy to shape into many forms while staying strong. |

| Durable | Resists rust, pressure, and damage from the environment. |

| Lightweight | Lighter than solid metal, useful for cars and planes. |

| Versatility in Design | Can be cut, bent, and shaped into complex and custom designs. |

These good points help companies make products that are strong, light, and not too expensive.

Industry Applications

Sheet metal fabrication is used in many jobs. New machines and tools help these areas grow fast.

HVAC

Sheet metal is used to make heating and air systems. Workers use it for ducts, vents, and covers. These parts must be strong and fit well. Sheet metal helps air move the right way in buildings.

Automotive

Car companies use sheet metal for car bodies, frames, and engine parts. People want cars that are light and strong. New laser cutters and welding machines help make these parts faster and better. Sheet metal forming lets car makers build safer and better cars.

Construction

Builders use sheet metal for roofs, wall panels, and beams. Cities and new buildings need strong and bendy materials. Sheet metal parts help builders make safe and lasting buildings.

Electronics

Electronics companies use sheet metal for cases, brackets, and heat sinks. New laser cutters help make these parts very exact. Sheet metal forming lets designers make special shapes for computers and phones.

Appliances

Appliance makers use sheet metal for washing machines, fridges, and ovens. The process helps make shells and frames that are strong and look nice. Sheet metal forming lets companies change designs quickly.

Note: Car and electronics companies use more sheet metal now. New machines help them make better parts faster.

Cost Considerations

Sheet metal fabrication helps companies save money. Steel and aluminum sheets cost less than big metal blocks. Machines do much of the work, so less time and money are needed. Fast work means products get to customers sooner. The process uses materials that can be recycled, so there is less waste and lower costs. Companies can pick from many metals and thicknesses to fit their budget.

The good points of sheet metal forming are saving money, making things fast, and having many design choices. These make it a smart pick for many jobs.

Quality and Design Considerations

Common Defects

Sheet metal forming makes strong products, but problems can happen. These problems change how good the part is. Workers and engineers look for these issues to keep things safe.

Warping

Warping happens when the heat or bending is uneven. The metal can twist or bend the wrong way. Warping makes the part not fit with others. Engineers use careful steps and cooling to stop warping.

Cracking

Cracking means the metal breaks or splits. This happens if too much force is used or the metal is too hard. Cracks make the part weak. Picking the right metal and using gentle steps helps stop cracks.

Burrs

Burrs are sharp edges or tiny pieces left after cutting. Burrs can hurt workers and damage other parts. Taking off burrs keeps things safe and smooth. Machines and careful steps help remove burrs.

Inaccurate Dimensions

Inaccurate dimensions mean the part is not the right size or shape. This can happen if machines are not set up right or the metal moves. Parts that are not accurate may not fit or work. Checking sizes during sheet metal forming helps keep quality high.

Tip: Checking often during sheet metal forming finds problems early and keeps quality good.

Quality Control

Quality control means checking each step to meet standards. Workers use tools to measure thickness, angles, and size. They look for warping, cracking, and burrs. Teams test samples from each batch. They use their eyes and machines to check results. Good records help fix problems and make future steps better.

A simple table shows what quality control checks:

| Check Type | What It Looks For |

|---|---|

| Visual Inspection | Surface defects, burrs |

| Measurement | Size, thickness, angles |

| Fit Testing | Part alignment, assembly |

| Strength Testing | Cracks, warping, durability |

Quality control keeps products safe and helps companies trust their sheet metal forming work.

Design Tips

Good design helps make better parts with sheet metal forming. Designers pick the right metal and thickness for each job. They plan bends and cuts to stop warping and cracking. Simple shapes make forming easier and better. Designers add ribs and flanges to make parts strong. They use CAD software to check steps before making real parts.

Designers follow these tips for better quality:

- Pick metals that fit the job and the forming steps.

- Use simple shapes for easy forming and fewer problems.

- Plan bends and cuts to stop stress and warping.

- Add support features for strength and quality.

- Check designs with software before starting forming.

Note: Careful design and planning in sheet metal forming makes better parts and fewer problems.

Sheet metal fabrication turns flat metal into things people use in many jobs. Workers cut, bend, and join the metal to make strong parts. These steps help make parts that fit just right. Learning about materials, tools, and uses helps people pick what they need. Good design and quality are important for every project. Many people go to a shop or use websites to order custom parts that work for them.

FAQ

Sheet metal fabrication changes flat sheets by cutting and bending. Workers also join pieces together. Machining starts with solid blocks or rods. It takes away material using drills or mills. Fabrication uses sheets, but machining uses blocks or rods.

Steel, aluminum, stainless steel, copper, and brass are used a lot. Each one has its own strength, weight, and rust resistance. People pick the material based on what the product needs and how much it costs.

Workers use plasma cutters, laser cutters, shears, and bandsaws. Each tool is best for certain thicknesses and shapes. Laser cutters make very exact cuts for small, detailed parts.

Many industries need sheet metal fabrication. Car makers, builders, electronics, HVAC, and appliance companies use it. They make strong, light, and special parts for their products.

Some problems are warping, cracking, burrs, and wrong sizes. These can make parts weak or not fit right. Checking quality helps stop these problems and keeps products safe.

Powder coating, painting, anodizing, galvanizing, and polishing are used. These finishes stop rust, make things look better, and help products last longer.

CAD software helps designers make plans and 3D models. It finds mistakes, gives ideas to fix them, and helps machines work right. CAD makes the work faster and more exact.

Tip: Picking the best material and finish makes products stronger and last longer.