When you machine aluminum alloy 6061 T6, always use sharp carbide tools and the right lubrication. Sharp tools and the right tool shape keep cuts clean. This helps stop the built-up edge from forming. Studies show that using the right tool angles and coatings, like TiN, controls heat and cutting forces. This makes machining more efficient and helps tools last longer for 6061-T6 aluminum. Coolant also helps keep things cool and makes the surface smoother. If you follow these tips, you get better results and your tools last longer when machining 6061-T6 aluminum.

Key Takeaways

- Use sharp carbide tools with the right shape and coatings. This helps you get clean cuts and makes tools last longer when machining 6061 T6 aluminum.

- Set the right speeds, feeds, and depths of cut. This will make the surface smoother, help tools last longer, and get more work done.

- Use good cooling and lubrication, like flood coolant or mist. This controls heat, stops tool damage, and keeps surfaces smooth.

- Hold your workpiece tightly with vises, clamps, or vacuum tables. This stops vibration and helps you make accurate cuts.

- Plan your toolpath and chip removal carefully. This stops chips from building up, lowers burrs, and keeps the area clean.

- Check and take care of your tools often. This helps you find wear early and stops sudden tool failures while machining.

- Do not make common mistakes like using the wrong tool shape, bad cooling, loose workholding, or skipping deburring. This will help you get better results.

- Work with skilled service providers like AFI Industrial Co., Ltd. They can give you expert machining, quality checks, and on-time delivery.

Table of Contents

Tool Selection

Picking the right tools is very important for CNC machining aluminum alloy 6061 T6. Good tool choices help you get a smoother finish and make your tools last longer. You also save time and work faster. Think about the cutting tool type, its shape, the coating, and how you care for your tools.

Cutting Tools

Carbide vs. HSS

Carbide tools are better than high-speed steel (HSS) tools for aluminum alloy 6061 T6. Carbide tools last longer and cut faster than HSS. They do not wear out as quickly. Carbide with less than 10% cobalt is best. This keeps the tool hard. It helps stop built-up edge and keeps the tool sharp. HSS tools get dull fast and do not handle heat well. Carbide tools give you steady results and less machine downtime.

Tool Geometry

The shape of your tool changes how chips move and how hot things get. For aluminum, you want:

- High positive rake angles (15°–20°) to lower cutting forces and heat.

- Large flute valleys to move soft, large chips away from the cut.

- Helix angles between 40° and 60°, with 50° being ideal for chip evacuation and smooth finishes.

- Sharp cutting edges with minimal edge prep to slice cleanly and prevent sticking.

- Polished flutes to reduce friction and help chips flow out.

- 2-3 flute tools for bigger chip channels and better chip removal.

Tip: A 12mm, 3-flute carbide tool with a 50° helix angle can give you a smoother surface and let you run 25% faster feed rates than standard tools.

Tool Coatings

Coating Types

The right coating helps your tools last longer and work better in CNC machining. Some coatings are better for aluminum:

- TiAlN and TiN/TiAlN coatings help tools last longer and improve surface finish at high speeds.

- PCD (polycrystalline diamond) coatings lower friction and stop aluminum from sticking to the tool.

- DLC (diamond-like carbon) coatings add hardness and reduce wear, especially in dry machining.

- ZrN (Zirconium Nitride) and TiB2 (Titanium Diboride) coatings reduce friction and gum-up, making them popular for aluminum.

Note: TiN coatings can work, but they may not be as effective as TiAlN or DLC for high-speed jobs.

Uncoated Tools

Uncoated carbide tools can work well, especially on small machines. They often give a better finish and let you cut more quickly. If you use a hobby CNC machine, uncoated tools might be best. For big jobs, coated tools last longer and cut smoother. Do not use coatings with aluminum, like AlTiN, because they can cause sticking and rough finishes.

Tool Maintenance

Inspection

Checking your tools often keeps them working well and saves time. You should:

- Check for dull edges, chips, or wear before each job.

- Replace tools that show signs of damage or excessive wear.

- Use sharp, coated tools to minimize material sticking and tool wear.

- Monitor tool performance and change tools as needed to avoid sudden failures.

Storage

Storing your tools the right way keeps them safe and ready to use. Keep tools in a clean, dry place. Use holders or racks so cutting edges do not touch. Label tools by type and size for easy picking. Keep coated and uncoated tools apart to stop damage.

AFI Industrial Co., Ltd. uses advanced CNC machines and skilled workers to pick the best tools and keep them in good shape for every job. Their team checks tools often and stores them well to make sure every project turns out great.

Machining Parameters

Setting the right machining parameters is key when you work with 6061-T6 aluminum. You need to choose the best speeds, feeds, and depths of cut to get a smooth finish and keep your tools in good shape. These choices help you avoid problems like built-up edge and tool wear. You also improve your productivity and part quality.

6061-T6 Aluminum Parameters

Speeds and Feeds

You should always start with the right cutting speed and feed rate for 6061-T6 aluminum. These values affect how fast you can machine and how good your surface finish will be. The table below shows the recommended values and their effects:

| Parameter | Recommended Value | Effect on Productivity and Quality |

|---|---|---|

| Cutting Speed | 600 m/min | Higher speed lowers cutting forces and improves surface roughness. |

| Feed Rate | 0.1 mm/rev | Higher feed rate increases material removal but may affect finish. |

| Depth of Cut | 1 mm | Deeper cuts remove more material but increase tool wear. |

| Rake Angle | 25° (positive) | Reduces cutting forces and improves tool life. |

| Lubrication | MQL | Lowers heat and improves tool life and finish. |

Tip: Faster cutting speeds help prevent built-up edge on your tools. When you increase the speed, the cutting forces drop. This makes it less likely for aluminum to stick to your tool. You get a cleaner cut and a better finish on your 6061-t6 aluminum parts.

Depth of Cut

Depth of cut is how deep your tool goes into the material with each pass. For 6061-T6 aluminum, a depth of cut around 1 mm works well for most jobs. If you need to remove a lot of material, you can use a deeper cut, but this will increase tool wear and may affect your surface finish. For finishing passes, use a shallower depth to get a smoother surface.

Chip Load

Chip load is the amount of material your tool removes with each tooth per revolution. Getting this right helps you avoid tool breakage and poor finishes.

Roughing vs. Finishing

When you rough out 6061-T6 aluminum, you want to remove material quickly. Use a higher chip load and a deeper cut. For example, a roughing pass might use a depth of cut of 0.04 inches and a feed rate of 35 IPM with a 3-flute cutter. This creates thick chips and stable cutting. For finishing, use a lower chip load and a shallower depth. Try a feed rate between 6 and 10 IPM and a depth of cut around 0.02 inches. This gives you a cleaner surface and reduces chatter.

Note: Always match your chip load to your tool size and spindle speed. Too high a chip load can break your tool. Too low a chip load can cause rubbing and poor surface quality.

Tool Alignment

Proper tool alignment is very important in the CNC machining of 6061-T6 aluminum. You need to make sure your tool is set up correctly to get accurate parts and a smooth finish.

Lathe Center Line

When you use a lathe, align your tool exactly with the center line of your 6061-T6 aluminum workpiece. Good alignment helps you hold tight tolerances, often as close as ±0.005 inches. It also helps you get a surface roughness as low as Ra 0.8 μm. If your tool is not aligned, you may see marks on your part, lose accuracy, or even damage your tool. Advanced CNC machining centers use special systems to check and adjust alignment, making it easier to get perfect results every time.

Tip: The high machinability and material properties of 6061-t6 aluminum make it easy to achieve great results with advanced milling techniques. When you combine precise tool alignment with the right parameters, you get parts with excellent dimensional accuracy and surface finish.

AFI Industrial Co., Ltd. uses advanced CNC machining and expert programming to set the best speeds, feeds, and alignment for every job. Their team checks each setup to make sure you get the highest quality and efficiency when machining aluminum. This approach helps you get consistent, high-quality results for all your 6061-T6 aluminum projects.

Lubrication & Cooling

Proper lubrication and cooling play a big role when you machine aluminum alloy 6061 T6. You need to control heat and remove chips to keep your parts accurate and your tools sharp. Let’s look at the best ways to do this.

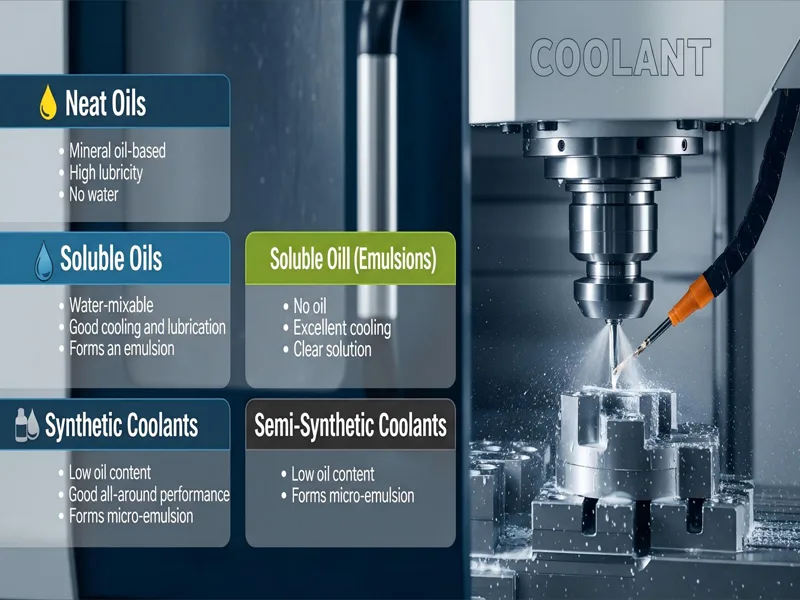

Coolant Types

Flood Coolant

Flood coolant uses a steady stream of liquid to cover the cutting area. Water-based emulsions work best for aluminum. These coolants lower the temperature and reduce friction between the tool and the workpiece. When you use flood coolant, you help prevent metal from deforming and stop your tool from breaking. Water-soluble coolants also help wash away chips, which keeps the cutting area clean. This method works well for high-speed machining. It helps you get a smooth surface and longer tool life.

Mist & Air Blast

Mist coolant sprays a fine mist of coolant onto the tool and workpiece. This method cools the cutting zone and helps with chip removal. Air blast uses compressed air to blow chips away from the cutting area. Air blast works well in dry machining. It keeps chips from sticking to the tool and reduces surface defects. High-pressure air at 6 bar can lower surface defects by up to 25%. You can use air blast with or without coolant, depending on your needs.

Tip: High-pressure coolant systems, especially those that send coolant through the tool, flush chips out of deep pockets. This reduces chip buildup by 40% compared to regular nozzles.

Chip Evacuation

Tool Path

You need to plan your tool path to help chips move away from the cutting area. Use chip breakers or inserts made for aluminum. These control chip length and stop long chips from clogging your tool. Some CNC machines have special cycles, like pecking or chip breaking, to help manage chip flow. Always avoid drilling without coolant. Chips can stick to the tool and cause clogging.

Air Blast

Air blast is a simple way to clear chips. Compressed air pushes chips away from the tool and workpiece. This keeps the cutting area clean and helps you get a better finish. Air blast also works well when you cannot use liquid coolant.

- Use chip breakers to control chip size.

- Plan tool paths that let chips fall away.

- Use an air blast for extra chip removal.

Heat Control

Preventing Distortion

Heat can cause aluminum to warp or change shape. You need to control the heat to keep your parts accurate. Water-based coolants remove heat quickly and lower the risk of distortion. When you keep the temperature low, you also lower residual stress in the part. This helps your finished parts stay the right size and shape.

| Aspect | 6061-T6 | 6061-T651 |

|---|---|---|

| Residual Stress | Higher due to quenching | Lower due to extra stretching step |

| Dimensional Stability | Good, but can distort under heat | Excellent, holds shape better during machining |

| Machinability | Can warp from heat and stress | More stable, better for precision machining |

Innovative tools with built-in cooling channels also help reduce heat. These tools keep the cutting area cool, lower tool wear, and improve your surface finish. When you control heat, you get more accurate parts and longer tool life.

Workholding

When you machine aluminum alloy 6061 T6, you need to hold your workpiece steady. Good workholding keeps your part from moving or vibrating. This helps you get accurate cuts and a smooth finish. Let’s look at the best ways to fix and support your parts.

Fixturing

Vises & Clamps

You can use vises and clamps to hold most aluminum parts. Vices work well for small parts or extrusions. They grip the workpiece tightly and keep it from shifting. Modular fixture systems let you adjust the setup for different shapes and sizes. For thicker aluminum plates, strap clamps on tables with tapped holes give strong support. Always place clamps above supports. This way, the force goes through the supports and does not bend your part.

- Use vises for small or regular-shaped parts.

- Strap clamps work best for thick plates.

- Modular fixtures help with odd shapes.

- Place clamps above supports to avoid bending.

Vacuum tables also help when you machine thin aluminum sheets. You can combine vacuum tables with mechanical fasteners or indexing pins. This stops the sheet from sliding during cutting. For extra stability, use hardened locators and supports. These parts do not wear out quickly and keep your setup accurate for many jobs.

Soft Jaws

Soft jaws are special inserts for your vise. You can machine them to match the shape of your part. This gives you a custom fit and spreads the clamping force. Soft jaws help prevent scratches and dents on aluminum. They also hold odd-shaped parts better than standard jaws.

Tip: Machine soft jaws from aluminum or plastic for the best grip on 6061 T6 parts.

Vibration Control

Support

Vibration can ruin your surface finish and cause tool marks. You need to support your workpiece well to stop it from shaking. Use fixed or adjustable supports under your part. These supports give stable contact points and stop the part from flexing. Fixture bodies like baseplates, angle plates, and tombstones add extra rigidity. When you clamp the above supports, you spread the force and keep the part flat.

- Fixed supports hold the part steady.

- Adjustable supports fit different part heights.

- Baseplates and angle plates add strength.

Power clamping systems, such as hydraulic or pneumatic clamps, give even pressure. They work fast and help reduce vibration. You get better repeatability and less setup time.

Damping

You can use vibration-dampening materials to cut down on chatter. MDF clamps and lead bricks absorb vibrations during machining. This makes your cuts smoother and protects your tools. Some shops use special pads or inserts under the part for extra damping.

Note: Always check that your supports and dampers are in good shape. Worn supports can cause your part to move or vibrate.

If you design your fixtures to allow multiple operations in one setup, you save time and keep your part stable. This reduces errors from moving the part between steps. Good workholding helps you get the best results when machining aluminum alloy 6061 T6.

Surface Finish

Achieving a smooth surface finish on aluminum alloy 6061 T6 takes careful planning and the right techniques. You want your parts to look clean and professional, with minimal burrs and a shiny finish. Let’s explore how you can reduce burrs and get the best results during the finishing pass.

Burr Reduction

Burrs are small, unwanted pieces of metal that stick out from the edges after machining. They can make your parts look rough and may cause problems during assembly. You can control burrs by adjusting your machining process.

Toolpath

You can reduce burrs by choosing the right toolpath and machining parameters. Here are some effective strategies:

- Adjust feed per tooth, depth of cut, spindle speed, and cutting speed to control burr size.

- Use lower spindle speeds to make burrs smaller.

- Select coated tools, which produce fewer burrs than uncoated ones.

- Choose tools with a small cutting-edge radius or tapered shape to limit burr formation.

- Plan your toolpath so the cutter exits the material in a way that reduces burrs, such as finishing on the up-milling side.

Recent studies show that burrs form mostly where the cutter meets the workpiece. You can also try cryogenic treatment on the workpiece surface to make the material harder and less likely to form burrs during micro-milling.

Deburring

Even with the best setup, you may still see some burrs. You should remove them to improve part quality. Here are some common deburring methods:

- Use a deburring tool or hand file to smooth sharp edges.

- Try abrasive pads or brushes for quick cleanup.

- For small or complex parts, use tumbling or vibratory finishing machines.

- Air blast or ultrasonic cleaning can help remove loose burrs after machining.

Tip: Reducing burrs during machining saves time and energy in post-processing. Always check your parts for burrs before moving to the next step.

Finishing Pass

The finishing pass is your last chance to improve the surface quality of your part. You want to use the right tools and settings to get a mirror-like finish.

Tool Choice

Pick sharp, high-quality carbide or HSS tools made for aluminum. Use a 2-flute endmill instead of a 4-flute cutter for a smoother finish. Keep your cutting speed high, between 800 and 1500 SFM, and use a moderate feed rate. Choose toolpaths like “Blend” or arc paths to avoid marks and get a more even surface. A good toolholder with minimal runout helps reduce vibration and tool marks.

- Use sharp, dedicated aluminum tools.

- Select a 2-flute endmill for finishing.

- Maintain high cutting speeds and moderate feeds.

- Optimize toolpaths for smooth movement.

Cleaning

After machining, clean your parts to remove any dust, chips, or coolant. Start with a soft brush or compressed air to clear away loose material. For a true mirror finish, polish the surface in stages. Begin with 400 grit abrasive paper, then move to 1200 grit, and finish with a diamond compound. Make sure you remove all scratches from each stage before moving to the next. Proper cleaning and polishing give your 6061 T6 aluminum parts a professional, flawless look.

A clean, polished part not only looks better but also performs better in its final application. Always finish strong for the best results.

Mistakes to Avoid

Tool Selection Errors

Picking the wrong tool can cause lots of trouble when you machine aluminum alloy 6061 T6. You must choose tools that fit the material and the job. Here are some mistakes you should not make:

- Improper flute count: Tools with too many flutes trap chips. Aluminum makes big chips, so use tools with 2 or 3 flutes. Too many flutes block chips and make rough surfaces.

- Incorrect helix angle: The helix angle changes how the tool cuts and moves chips. For roughing, use a 35°–40° helix angle. For finishing, a 45° angle is best. The wrong angle can make the tool chatter or cut weakly.

- Inadequate chip evacuation: If your tool’s flute shape or chipbreaker is wrong, chips get stuck. This causes heat and a bad surface.

- Tool deflection issues: If you forget about the tool’s core diameter, the tool can bend. This makes parts the wrong size and can break the tool or part.

Some machinists check the cutter diameter instead of the core diameter for deflection. Always keep the tool short from the holder to the tip. This gives you better accuracy and part quality.

Tip: Use tools made for aluminum with the right flute count and helix angle. This stops chip problems and keeps your parts looking good.

Parameter Mistakes

Wrong machining parameters can break tools or ruin your part’s finish. Always check your speeds, feeds, and depth of cut. The table below shows common mistakes and how to fix them:

| Parameter Mistake | Tool Failure Mode | Cause and Impact | Mitigation |

|---|---|---|---|

| Excessive loads and shock loading | Chipping | Nicks and flaking on cutting edges, poor finish, tool failure | Reduce vibration, adjust speeds and feeds, avoid repeated entries |

| Extreme temperature fluctuations | Thermal cracking | Cracks on cutting edge, early tool failure | Use proper coatings, spread heat with efficient toolpaths |

| Improper speeds, feeds, depth | Fracture | Sudden breakage from overload or deflection | Optimize parameters, ensure rigidity, use correct depth, secure tool holding |

| Poor tool holding | Fracture | Tool runout and pullout, broken tools, scrapped parts | Use hydraulic or shrink fit holders, check setup rigidity |

| Improper tool entry methods | Tool failure, poor finish | High stress on tool during plunge, early wear or breakage | Use ramping to reduce cutting forces and extend tool life |

Always check your tool and workholding setup. Hold your part tight to stop vibration and chatter. Pick the right toolpath to lower tool stress.

Cooling Issues

Cooling is very important when you machine 6061 T6 aluminum. If you do not control the heat, your tool can wear out fast, and your part can warp. Here are cooling mistakes to avoid:

- Not using enough coolant or lubricant. This can make the tool overheat and wear out fast.

- Using the wrong coolant type. Water-based coolants work best for aluminum. Oil-based coolants can make sticky chips.

- Poor chip removal. If chips stay in the cut, they trap heat and hurt the tool and part.

- Not aiming the coolant at the cutting zone. Coolant must reach the tool tip to work well.

Note: Always use lots of coolant and make sure it goes right where the tool meets the part. This keeps your tool cool and your parts accurate.

Workholding Problems

Workholding mistakes can ruin your machining results. If you do not secure your aluminum 6061 T6 part well, you may see chatter, poor surface finish, or even tool breakage. You need to check your setup before you start cutting.

- Loose clamps let the part move. This causes vibration and leaves marks on the surface.

- Using the wrong vice or fixture can bend or damage your part.

- Not supporting thin parts leads to flexing. This makes it hard to hold tight tolerances.

- Over-tightening clamps can crush soft aluminum. You may see dents or warping.

You should always match your workholding method to the size and shape of your part. For thin plates, use vacuum tables or soft jaws. For small parts, a precision vise works best. Add supports under the part to stop flexing. Check that all clamps and fixtures are clean and free from chips. A dirty setup can cause misalignment.

Tip: Place clamps close to the cutting area. This reduces vibration and keeps your part steady.

A good workholding setup helps you get accurate cuts and a smooth finish. Take time to plan your fixturing before you start the machine.

Maintenance Lapses

Skipping regular maintenance can lead to tool failure and lost production time. You must keep your tools and machines in top shape to get the best results with aluminum 6061 T6.

- Tools can fail from abrasive wear, chipping, or thermal cracking.

- Aggressive or weak cutting parameters speed up tool wear.

- Inconsistent coolant use shortens tool life.

- Poor process control leads to sudden tool breakage.

You should inspect your tools before each job. Look for dull edges, chips, or cracks. Replace worn tools right away. Keep your coolant system clean and filled. Monitor cutting parameters and adjust them if you see signs of trouble. Group similar parts together to make tool changes faster and reduce downtime.

| Maintenance Task | Why It Matters | What Can Go Wrong |

|---|---|---|

| Tool inspection | Stops sudden failures | Broken tools, bad parts |

| Coolant system check | Keeps tools cool and sharp | Overheating, tool wear |

| Process control | Maintains quality and efficiency | Scrap, lost time |

| Tool condition monitor | Prevents downtime | Machine stops, missed deadlines |

Regular maintenance keeps your shop running smoothly. You save money and avoid costly delays.

Skipping Deburring

If you skip deburring, your parts may have sharp edges or leftover metal. These burrs can cause injuries, make assembly hard, or damage other parts. You should always check for burrs after machining.

- Burrs can scratch or cut workers during handling.

- Sharp edges may not fit well in assemblies.

- Leftover metal can break off and cause problems in machines.

You can remove burrs with hand tools, abrasive pads, or tumbling machines. For small or complex parts, use brushes or ultrasonic cleaning. Always inspect your parts before shipping or assembly.

Note: Clean, burr-free parts look better and work better. Deburring is a simple step that makes a big difference.

By avoiding these common mistakes, you improve your machining results and keep your shop safe and efficient.

Service Providers

AFI Industrial Co., Ltd.

AFI Industrial Co., Ltd. gives precise machining for aluminum alloy 6061 T6. They make custom parts that match what you need. Many businesses trust AFI because they work fast and have high standards. Their team helps you finish projects on time with good results.

Precision Machining Services

You want the best aluminum for CNC machining. AFI uses advanced machines to meet strict rules. Their equipment includes CNC turning centers, five-axis CNC mills, welding stations, electroplating units, and die casting machines. You get parts with tight tolerances, like ±0.01mm for flute parts and ±0.02mm roundness in whistle head cavities. AFI controls internal thread tolerance at the H5 level for smooth assembly.

AFI uses special cutting methods, like 3D curved surface cutting and mirror polishing. These help lower airflow turbulence and make the sound clearer in parts. They also use low-temperature ion nitriding to make surfaces harder than HV800. This process makes parts three times more wear-resistant than regular silver plating. AFI checks air tightness with dynamic balance detection to meet a 0.02MPa leakage standard.

You benefit from real-time monitoring of key production steps. AFI uses advanced testing tools, like three-dimensional detectors, to inspect every part. Their team improves production to work faster and deliver sooner. You get your aluminum alloy 6061 T6 parts quickly and with high quality.

AFI Industrial Co., Ltd. gives you one-stop help. You can get support with design, drawing, programming, cutting, manufacturing, finishing, assembly, and packaging. This makes your job easier and saves you time.

Quality Control

AFI cares about quality control. You get parts that meet world standards. Their certifications and checks make them different from other companies.

| Certification/Standard | Description |

|---|---|

| ISO 9001:2015 | Certified quality management system for steady quality. |

| ITAR Compliance | Follows International Traffic in Arms Regulations for controlled materials. |

| CITES Material Specs | Meets Convention on International Trade in Endangered Species material rules. |

| Quality Control Measures | Description |

|---|---|

| 78 Process Quality Control Nodes | From material checks to finished product testing, for military-grade stability. |

| Material Selection | Only uses approved suppliers for aluminum alloy 6061 t6. |

| Accuracy and Tolerance | Keeps tight control within customer drawing limits. |

| Performance Index Control | Quality team checks to meet customer performance needs. |

| Durability | Surface treatment after processing to make parts last longer. |

| Compatibility Checks | Makes sure parts fit and work with other accessories as drawings show. |

| 100% Full Inspection | Coordinate Measuring Machine (CMM) checks before shipping for precision. |

You feel safe knowing AFI checks every part before shipping. Their team uses CMM inspection to make sure your parts are exact. You can trust AFI to give you quality and reliability for every order.

You can get great results when machining aluminum alloy 6061 T6 if you follow some important steps.

- Use sharp carbide tools to make clean cuts.

- Select the optimal speeds, feeds, and depths for consistent machining.

- Use good cooling and lubrication to keep things cool.

Research shows that changing cutting settings can save 14.41% energy and make surfaces over 360% smoother. You should look at your process and think about getting help from AFI Industrial Co., Ltd. for better quality and steady results.

FAQ

You should use sharp carbide tools with a high helix angle. These tools cut cleanly and last longer. Carbide tools also help you avoid built-up edge and get a smooth finish.

Apply plenty of coolant or lubricant. Use tools with polished flutes and the right coatings, like ZrN or DLC. These steps help you keep chips moving and stop aluminum from sticking.

You can start with a cutting speed of 600 meters per minute. Higher speeds help you get a better surface and reduce tool wear. Always check your machine’s limits before increasing speed.

Burrs form when the tool pushes metal out instead of cutting it cleanly. You can reduce burrs by using sharp tools, adjusting your feed rate, and planning your toolpath to exit cleanly.

Use vacuum tables or soft jaws. Add supports under the part to stop flexing. Clap gently to avoid dents. These methods help you keep thin parts flat and accurate.

You can machine it dry, but you may see more heat and tool wear. Using coolant or mist helps you control temperature and get a better finish.

Check your tools before each job and after long runs. Look for dull edges or chips. Replace worn tools right away to keep your parts accurate and your process smooth.

Use air blast or flood coolant to clear chips. Plan your toolpath so chips fall away from the cut. Good chip removal helps you avoid tool damage and keeps your surface clean.