The most common surface treatments for stainless steel in 2025 are electroplating, painting, powder coating, anodizing, galvanization, passivation, and plasma treatment. Manufacturers use these methods to make stainless steel stronger. These treatments help stop rust and make the surface look nicer. Data shows that finishing and hardening the surface can lower rust, especially for 316 stainless steel. The right surface treatment helps products last longer and look better.

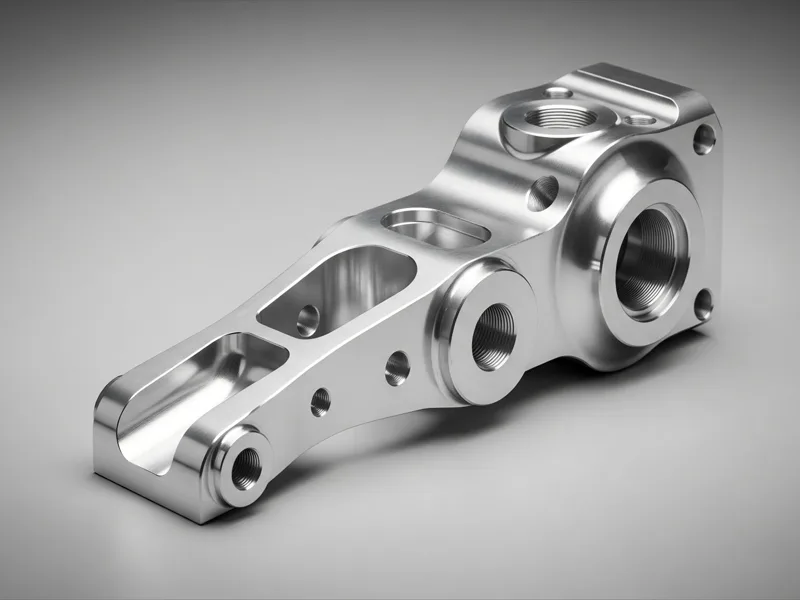

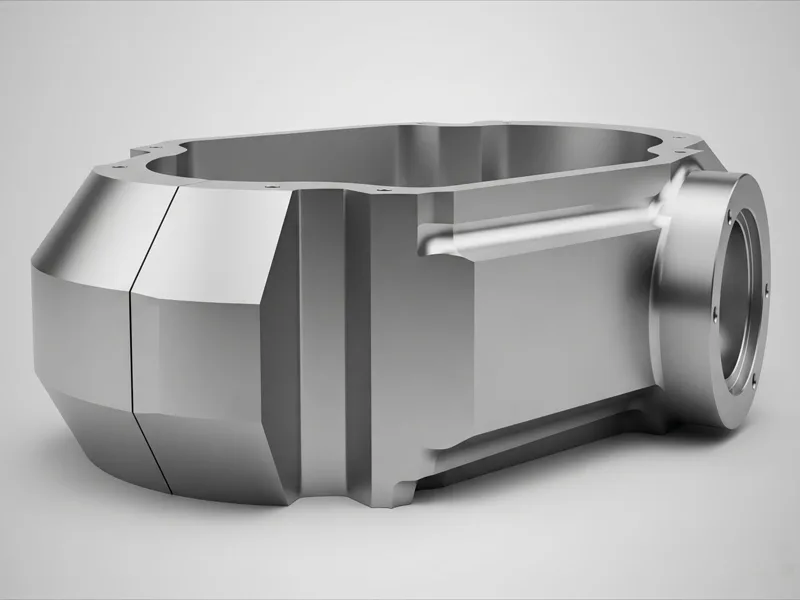

AFI Industrial Co., Ltd. offers careful machining and surface finishing for stainless steel. They work with 316 stainless steel to meet high industry standards.

Key Takeaways

- Surface treatments like polishing, passivation, and coating help stainless steel get stronger and stop rust. Mechanical polishing makes stainless steel smooth and shiny. This makes it easy to clean and ready for other finishes. Electropolishing gives a mirror-like surface that fights rust and keeps parts very clean. Passivation makes a shield that stops rust and fixes the metal after welding or cutting. Pickling cleans the metal by taking away dirt and gets it ready for more treatments. Sandblasting and bead blasting give stainless steel a dull look that hides marks and helps coatings stick better. Mirror polishing makes stainless steel very shiny, simple to clean, and good for places that need to be clean and look nice. Picking the best treatment depends on the metal type, how it will be used, the budget, and how it will be cleaned. Experts can help choose the right one.

Table of Contents

Surface Treatments for Stainless Steel

Mechanical Polishing

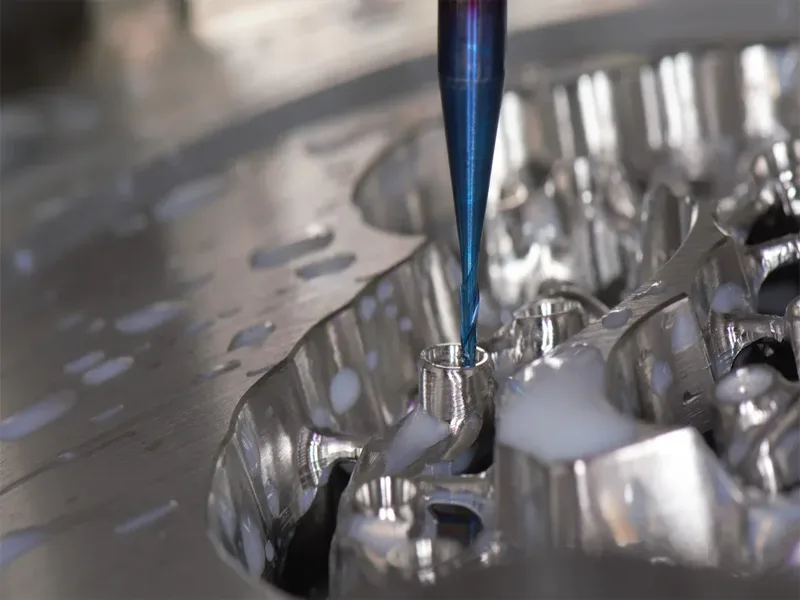

Mechanical polishing uses abrasives and buffing wheels to make stainless steel smooth and shiny. This process takes away scratches and rough spots from the metal. Workers use grinders, sanders, and polishing pads for this job. They do this to get the finish they want. Mechanical polishing is a popular way to treat stainless steel, especially 316 stainless steel parts.

Benefits

- Makes the surface smooth and easy to clean, so dirt and bacteria do not stick.

- Makes the metal look bright and even.

- Helps stop rust by removing flaws on the surface.

- Gets the metal ready for other finishes, like electropolishing or coating.

- Let’s you pick how rough or shiny you want the surface, from brushed to mirror.

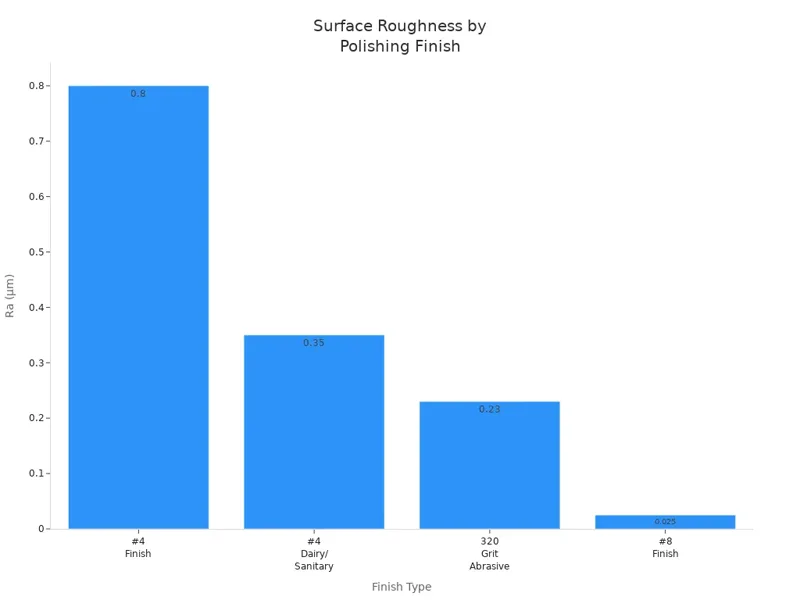

| Finish Type / Grit Size | Typical Ra Range (µm) | Description |

|---|---|---|

| #4 Finish | ~0.8 | Standard brushed finish |

| #4 Dairy/Sanitary | 0.3 – 0.4 | Smoother brushed finish |

| #8 Finish | ~0.025 | Highly buffed, nearly flawless |

| 320 Grit Abrasive | 0.21 – 0.25 | Fine grit mechanical polishing |

Applications

Mechanical polishing is used in many industries that need good looks and strong parts. Some examples are:

- Food processing equipment and kitchenware

- Medical devices and surgical tools

- Architectural panels and handrails

- Automotive trim and decorative parts

- Pharmaceutical machinery

AFI Industrial Co., Ltd. does mechanical polishing as part of its work. They make sure 316 stainless steel and other alloys look and work well.

Electropolishing

Electropolishing is a special electrochemical way to treat stainless steel. In this process, the stainless steel part is the anode in an acid bath. The bath usually has sulfuric and phosphoric acids. A direct current goes through the part and removes a thin layer of metal. This makes the surface smooth at a tiny level. Electropolishing is a top choice for a bright, clean, and rust-resistant finish.

Benefits

- Gives a mirror-like, smooth surface that is very clean.

- Makes the chromium oxide layer stronger, so it resists rust better.

- Takes away burrs and sharp edges, which helps stop contamination.

- Makes the surface less rough, so cleaning is easier and bacteria have less space to grow.

- Improves the passive film, which protects against rust and wear.

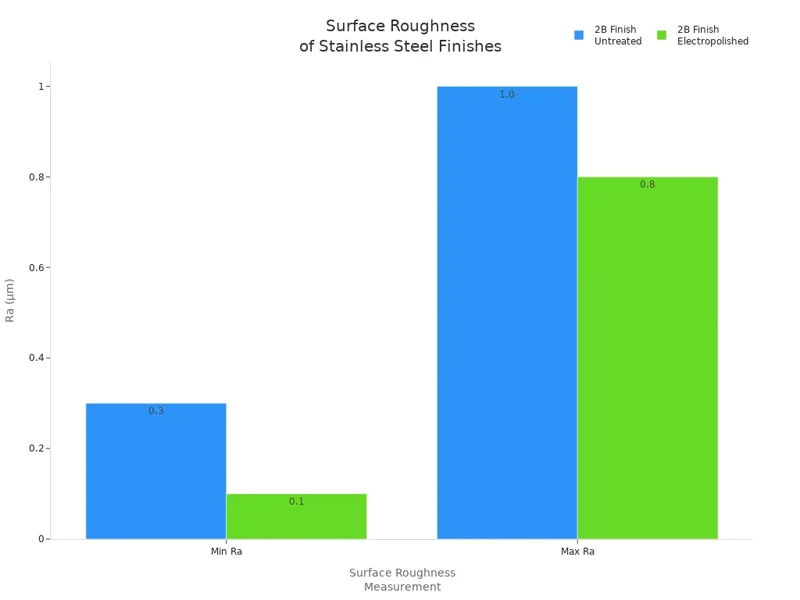

| Feature | 2B Finish (Untreated) | 2B Finish (Electropolished) |

|---|---|---|

| Surface Description | Semi-reflective | Mirror-like, smooth |

| Surface Roughness (Ra) | 0.3 – 1.0 µm | 0.1 – 0.8 µm |

| Corrosion Resistance | Moderate | Enhanced |

| Common Applications | Food, pharma | Injectable pharma, clean food |

Applications

Electropolishing is great for industries that need very clean and rust-resistant parts. Some common uses are:

- Pharmaceutical and biotechnology equipment

- Food and beverage processing machinery

- Medical implants and surgical instruments

- Semiconductor and electronics manufacturing

- Marine and chemical processing components

AFI Industrial Co., Ltd. uses electropolishing to give stainless steel the right surface. Their work meets strict rules for 316 stainless steel parts.

Passivation

Passivation is a chemical way to treat stainless steel. It removes free iron and dirt from the surface. The metal goes into an acid bath, like nitric or citric acid. This makes a protective chromium oxide layer. The layer keeps out water and chemicals. This helps the metal resist rust and last longer.

Benefits

- Makes the metal resist rust by forming a stable, self-healing oxide layer.

- Takes away dirt that can cause rust or stains.

- Brings back the protective layer after welding or machining.

- Meets rules like ASTM A967 and AMS 2700 for quality.

- Lowers the need for repairs and makes the part more reliable.

Passivation is very important for 316 stainless steel in tough places. It helps keep the surface strong and makes it last longer.

Applications

Passivation is needed in industries where rust resistance and cleanliness matter a lot. Some examples are:

- Medical devices and surgical implants

- Aerospace components and fasteners

- Food and beverage processing tanks and filters

- Automotive engine parts

- Electronics and semiconductor equipment

AFI Industrial Co., Ltd. offers passivation as part of its surface finishing. They make sure stainless steel parts meet high standards and last a long time.

Pickling

Pickling treatment is a chemical process that cleans stainless steel. Workers use pickling to take off unwanted layers. Acids are used to remove iron oxides and heat tint. This also gets rid of other things on the surface. Pickling makes the surface of 316 stainless steel clean and even.

Benefits

Pickling gives stainless steel many good things:

- Takes away iron oxides, scale, heat tint, and free iron.

- Helps a new oxide layer form to stop rust.

- Gets the metal ready for more finishing, like passivation.

- Makes 316 stainless steel parts look better and cleaner.

- Lowers the chance of rust, pitting, and other problems.

Good pickling helps stop rust and keeps out bad things like iron and sulfides. It also helps stop pitting and uneven surfaces.

The table below lists acids and other details for pickling:

| Aspect | Details |

|---|---|

| Acids Used | Hydrochloric acid (10-20%), Nitric acid, Citric acid |

| Temperature Range | 20-60°C |

| Immersion Time | 10 seconds to 5 minutes |

| Agitation Intensity | Gentle to strong, based on surface area |

| Contaminants Removed | Iron oxides, heat tint, scale, free iron, grease, oils, dirt, foreign deposits |

| Pre-treatment | Degreasing, brushing, abrasive blasting |

| Post-treatment | Rinsing, neutralizing, passivation or oiling |

Applications

Pickling is used for many stainless steel products. It is common in places that need clean and strong metal. Some uses are:

- 316 stainless steel tanks, pipes, and fittings in chemical plants

- Food equipment that must stay clean and not rust

- Pharmaceutical machines where hygiene is very important

- Marine hardware that touches saltwater

- Heat exchangers and welded parts

Pickling is often the first step before other finishes. AFI Industrial Co., Ltd. uses pickling to get 316 stainless steel ready for more treatments. Their work makes sure each part is high quality and works well in hard places.

Additional Stainless Steel Surface Treatments

Sandblasting

Sandblasting is a common way to finish stainless steel. Workers use strong air to shoot tiny, rough pieces at the metal. This knocks off rust, old paint, and rough spots. Sandblasting makes the metal feel even and gets it ready for paint or coating.

Benefits

Sandblasting gives stainless steel many good things:

- Makes a dull or soft shine that does not reflect much light.

- Hides small marks and keeps fingerprints away.

- Helps paint and coatings stick better.

- Let’s you pick how rough or smooth you want the surface.

- Cleans the metal well so it is ready for more work.

The kind of rough pieces used in sandblasting changes how the metal looks. The table below lists some types and what they do:

| Abrasive Type | Description | Effect on Stainless Steel Surface |

|---|---|---|

| Glass Beads | Rounded, lead-free soda-lime glass | Creates smooth, satin-like finish; less aggressive, ideal for cleaning and polishing |

| Ceramic Beads | Harder, sharper, often aluminum oxide based | Produces smooth, matte finish; suitable for polishing and etching |

| Steel Shot | Durable carbon steel particles | Provides smooth, glossy finish; used for peening, deburring, surface hardening |

| Aluminum Oxide | Angular particles, highly abrasive | Removes hard impurities; creates rougher texture |

Applications

Sandblasting is used in lots of jobs. People use it to clean, get ready, or finish stainless steel parts. Some examples are:

- Building panels and fancy surfaces

- Machines and factory tools

- Car parts and frames

- Boat parts and ship pieces

Sandblasting stainless steel has a few steps:

- Clean the metal and hold it in place.

- Pick the right rough pieces, like glass beads or aluminum oxide.

- Set the machine for the right pressure and nozzle.

- Move the nozzle over the metal in an even way.

- Clean the part again to get rid of any leftover bits.

Sandblasting gives a soft, dull look with a little texture. You can change the look by using different rough pieces or settings. This makes sandblasting a good choice for many finishing jobs.

Sandblasting makes a surface that does not shine and hides marks. It also keeps fingerprints away. This finish is good for both factories and decoration.

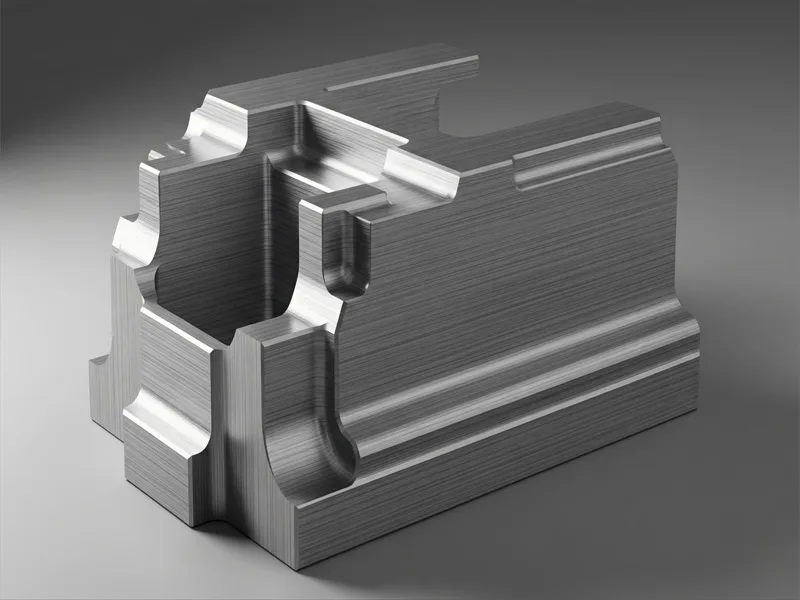

Brushing

Brushing gives stainless steel a special look. Workers use rough brushes to make thin, straight lines on the metal. This gives the metal a soft, lined texture. Many people like brushing because it looks modern and works well.

Benefits

Brushing has many good points:

- Makes a cool, lined pattern.

- Hides tiny scratches and marks.

- Helps stop new scratches.

- It is a cheap and quick way to finish metal.

- It is easier to clean than rougher finishes.

Brushing is used when something needs to look nice and work well. The finish lasts long and makes stainless steel look neat and tidy.

Applications

Brushing is used in many places. Some examples are:

- Kitchen sinks and appliances

- Elevator doors and wall covers

- Handrails and building trim

- Car parts inside and outside

- Cases for electronic devices

Brushing is great for things that need to look new and stylish. It also helps smooth out sharp edges while making.

Bead Blasting

Bead blasting is another way to finish stainless steel. Workers shoot small glass or ceramic beads at the metal very fast. This makes the metal look even and dull, with no lines.

Benefits

Bead blasting helps in many ways:

- Makes a smooth, soft, dull surface.

- Helps stop rust from forming.

- Hides fingerprints and small marks.

- Makes the metal last longer and look the same everywhere.

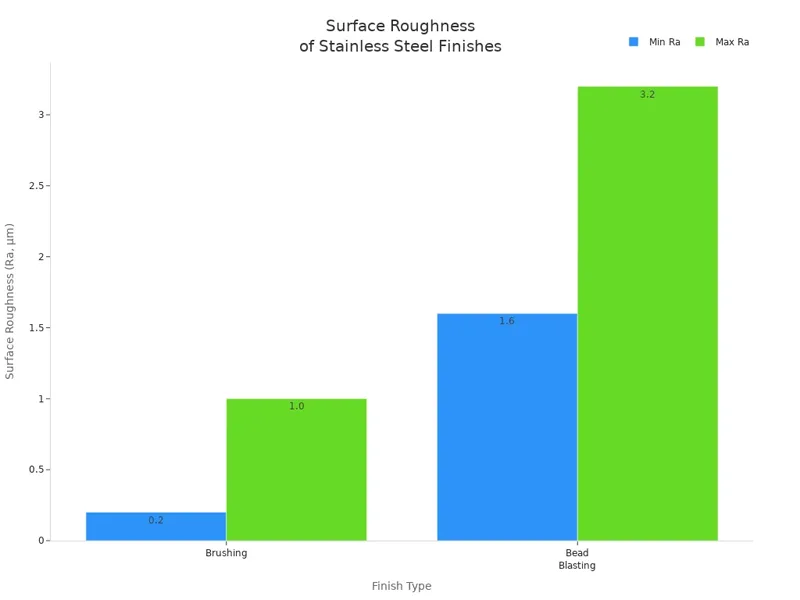

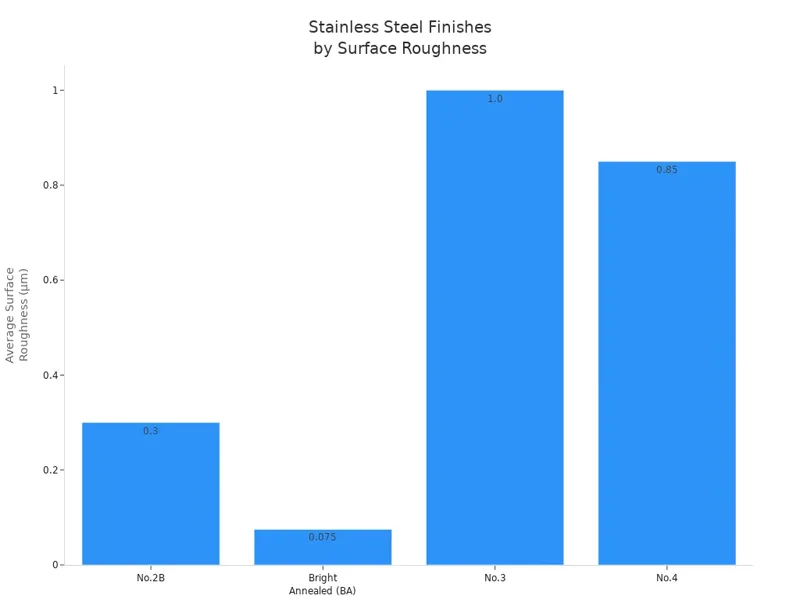

The chart below shows how rough brushing and bead blasting are:

Bead blasting makes tiny bumps on the metal. This keeps fingerprints away and helps the metal stay clean.

Applications

Bead blasting is used in many areas. Some examples are:

- Medical tools and surgical items

- Food machines and equipment

- Airplane and car parts

- Fancy panels and fixtures

Bead blasting is good for things that need to look even and nice. It also helps stainless steel parts work better and last longer.

Mirror Polishing

Mirror polishing makes stainless steel very shiny and smooth. Workers use special fine abrasives and buffing compounds. These tools take away all scratches and marks. The metal ends up looking like glass and shines a lot. Many companies pick mirror polishing for its clean look and helpful features.

Benefits

Mirror polishing has many good points:

- The surface gets very smooth, so cleaning is simple. Dirt and germs cannot hide anywhere.

- The shiny finish bounces light, making rooms look bigger and brighter.

- The process takes away tiny cracks and flaws, which helps stop rust.

- Mirror finish treatment helps the metal fight chemicals and water.

- The polished surface does not show fingerprints or smudges as much as rougher finishes.

- Products with a mirror surface often look fancy and nice.

Mirror polishing is a great choice for places that need to look good and stay clean. Hospitals, kitchens, and fancy buildings often use this finish.

Applications

Many companies use mirror polishing for style and function. The table below lists common uses in the building and medical fields:

| Industry | Common Applications of Mirror Polished Stainless Steel |

|---|---|

| Architectural | – Outside walls (building curtain walls) – Inside decoration (walls, columns, railings) – Furniture design (fancy furniture frames, decorative pieces) – Building parts (column covers, wall panels, signs) |

| Medical | – Ultra mirror finishes for medical equipment – Surfaces that need easy cleaning and strong rust protection |

Architects often pick mirror finishes for outside walls, wall panels, and trim. These surfaces reflect what is around them and look modern. Designers use mirror-polished stainless steel for furniture, signs, and even art. The famous “Bean” sculpture in Chicago uses this finish to look amazing.

In the medical field, mirror polishing helps keep tools clean. The smooth surface does not trap germs, so cleaning is quick and easy. Hospitals and labs use mirror-polished tables and tools to meet strict cleaning rules.

Some products mix mirror polishing with other finishes. For example, elevator doors may have both mirror and brushed spots for a cool look. This mix adds style and texture to public places.

Mirror polishing is special because it looks great, stays clean, and lasts a long time. Many fancy projects use this finish for both good looks and strong performance.

Chemical and Electrochemical Surface Treatment Methods

Chemical and electrochemical treatments change how stainless steel looks and works. These methods can add color or make the metal resist rust better. They can also give the surface special textures. Many companies use these treatments to meet design needs. They also help products last longer.

Etching

Etching uses chemicals or electricity to take away parts of the metal’s surface. This makes patterns, textures, or marks that can look nice or be useful. Workers use a photoresist to cover spots that should not be etched. Then, they put acids like ferric chloride or copper chloride on the open metal. The acid eats away the metal that is not covered. Etching works well for 304 and 316 stainless steel.

Benefits

- Makes detailed designs and logos on stainless steel.

- Adds texture so things are easier to hold.

- Gets the surface ready for more finishing steps.

- Let workers make the same pattern many times.

Etching gives a dull finish that hides fingerprints and small scratches.

Applications

- Decorative panels and signs

- Nameplates and control panels

- Medical tools with marks for measuring

- Non-slip floors and handles

Etching is used in electronics, buildings, and medical tools. It helps companies add logos or safety features to their products.

Coloring

Coloring changes the color of stainless steel without using paint. This can be done with lasers, chemical baths, or PVD. Lasers heat the metal to make thin oxide films. PVD puts a thin layer of special compounds on the metal in a vacuum. These ways make bright colors that last a long time.

| Coloring Technique | Description | Typical Colors |

|---|---|---|

| Laser Coloring | Uses heat to form oxide films | Blue, gold, purple |

| PVD | Deposits thin films in vacuum | Gold, black, blue |

| Chemical Bath | Forms oxide layers in acid | Bronze, rainbow |

Benefits

- Makes many colors, so designers have choices.

- Does not peel or chip like paint does.

- Makes the surface harder.

- Keeps the metal’s rust resistance.

Coloring gives products a special look but keeps them strong and easy to clean.

Applications

- Building panels and trim

- Watches, jewelry, and fashion items

- Kitchen tools and appliances

- Elevator doors and fancy hardware

Coloring is popular in industries that want style and strong products.

Coating

Coating puts a protective or pretty layer on stainless steel. Common coatings are nickel plating, chrome plating, and special ceramic or organic layers. These can be put on by electroplating or spraying. Coatings help the metal look better and protect it from damage.

Benefits

- Makes the metal resist rust and wear better.

- Adds a shiny or dull look for style.

- Helps parts last longer by reducing wear.

- Gives extra protection in tough places.

Coatings also make cleaning easier and help products meet rules.

Applications

- Car parts and trim

- Food processing machines

- Medical tools and devices

- Boat parts and outdoor fixtures

Many companies use coatings to make stainless steel look good and work better. Coatings are important for making parts last and look nice.

Stainless Steel Surface Finishes

2B Finish

The 2B finish is the most used finish for stainless steel. Factories make this finish by rolling the steel when it is cold. Then, they heat the steel and pickle it to clean off dirt. After that, polished rollers give the steel a smooth, gray look. The 2B finish is not shiny like a mirror, but it is smooth and a little shiny. This finish looks nice and works well for many jobs.

Benefits

- The 2B finish is smooth and even, so it is easy to clean.

- It helps stainless steel fight rust, so parts last longer.

- This finish does not cost much and fits many uses.

- The 2B finish meets ASTM and ISO rules, so it is of high quality.

- It is tough and does not scratch easily.

The 2B finish is a smart pick for many jobs because it is simple to keep clean and always looks neat.

Applications

Many businesses use the 2B finish because it works in lots of ways. Some common uses are:

- Kitchen sinks and appliances

- Food and drink machines

- Building panels and trim

- Medical tools and hospital equipment

- Car parts and factory machines

The 2B finish is good for places that need to be clean and strong. People also like it where things should look nice but do not need to shine like a mirror.

| Finish Name | Description & Characteristics | Typical Applications | Industry Standard Reference | Surface Roughness (Ra) |

|---|---|---|---|---|

| No.2B | Cold rolled, annealed, pickled, final pass with polished rollers; smooth, moderately reflective | Chemical, food processing, architectural uses | ASTM A480, EN standards | 0.1 – 0.5 μm |

Patterned and Embossed Finishes

Patterned and embossed finishes give stainless steel a cool texture and design. Factories use special machines to press shapes into the metal. These shapes can be waves, squares, or water ripples. The process makes a pattern you can see and feel.

Benefits

- Patterned and embossed finishes make stainless steel look fun and stylish.

- The texture hides fingerprints and small scratches.

- Some patterns help stop people from slipping, so it is safer.

- These finishes add depth and can make panels stronger.

- There are many designs, so designers have lots of choices.

Patterned and embossed finishes look good and work well, so they are used in new buildings and busy places.

Applications

Many businesses use patterned and embossed finishes for style and safety. Some common uses are:

- Wall covers and ceilings in buildings

- Elevator walls and doors

- Kitchen counters and equipment

- Car trim and panels

- Fancy panels and signs

To make these finishes, workers pick the right steel and design the pattern. They clean the metal and press the pattern into the surface. After embossing, they clean and polish the sheets to make them look great.

| Finish Designation | Description & Processing | Typical Applications | Surface Appearance / Roughness |

|---|---|---|---|

| Embossed/Patterned | Created by die or roller stamping; raised or depressed designs | Architecture, elevators, kitchen equipment | Textured, anti-slip, decorative |

Patterned and embossed finishes help stainless steel look special and work better.

Choosing the Right Stainless Steel Surface Treatment

Factors to Consider

Picking the best stainless steel surface treatment is important. Each industry needs something different. Food and drink companies care about cleanliness and long-lasting tools. They must clean the metal first to get rid of dirt. Passivation helps bring back the protective layer. Polishing makes the surface smooth so bacteria cannot stick. These steps help meet tough rules for clean and strong equipment.

When you pick a surface treatment, think about these things:

- What you want, like stopping rust, smoothness, or easy cleaning

- The type of stainless steel, such as 316 stainless steel, which fights rust well

- Safety and the environment, especially if you use chemicals

- How much money you can spend

- How fast you need the job done

- What the part will be used for, like food safety or looking nice in buildings

- If the treatment is right for the job

Looking at all these points helps you make the best choice for your project.

Comparison Table

The table below shows common ways to finish stainless steel. It lists their main good points, best uses, and how they fit different jobs.

| Surface Treatment Option | Main Benefit | Best For | Typical Use Cases | 316 Stainless Steel Suitability |

|---|---|---|---|---|

| Mechanical Polishing | Smooth, clean surface | Hygiene, easy cleaning | Food, pharma, medical | Excellent |

| Electropolishing | Mirror finish, high corrosion resistance | Ultra-clean, smooth finish | Medical, biotech, marine | Excellent |

| Passivation | Enhanced corrosion resistance | Restoring protective layer | Aerospace, food, pharma | Essential |

| Pickling | Removes scale, prepares surface | Pre-treatment, weld cleaning | Chemical, marine, fabrication | Very Good |

| Sandblasting | Matte texture, hides flaws | Decorative, prep for coating | Architecture, automotive | Good |

| Brushing | Modern look, hides scratches | Appliances, interiors | Kitchen, elevators, electronics | Good |

| Bead Blasting | Uniform matte finish | Non-reflective, clean look | Medical, food, aerospace | Very Good |

| Mirror Polishing | High shine, easy cleaning | Decorative, hygiene | Architecture, medical | Excellent |

Decision Guide

To pick the right surface treatment, follow these steps:

- Decide what you want most. Does the part need to stop rust, be smooth, or look special?

- Check what kind of stainless steel you have. For tough places, 316 stainless steel is best.

- Think about where the part will be used. Will it touch chemicals, water, or get hot?

- Look at your budget and how much time you have. Some finishes cost more or take longer.

- Match the treatment to the job. For food or medical use, pick smooth, easy-to-clean finishes.

- Check if there are any rules or standards you must follow. Some jobs need special tests or certified finishes.

Tip: If your project is hard or you are not sure, ask experts like AFI Industrial Co., Ltd. Their team can help you pick the best stainless steel surface treatment for your needs.

Picking the best surface finishing for stainless steel helps it last longer and look nicer. The table below shows how each method helps 316 stainless steel:

| Surface Treatment | Key Benefits |

|---|---|

| Mechanical Polishing | Makes the surface smooth, takes away flaws, and helps stop rust. |

| Electropolishing | Gives a clean, smooth finish and helps keep things safe for food and medical use. |

| Passivation | Builds a shield that stops rust and helps equipment last longer. |

| Pickling | Cleans off flaws and gets the surface ready for more work. |

| Sandblasting | Makes the surface even and dull, and helps coatings stick better. |

| Brushing | Gives a special look and hides small scratches. |

| Mirror Finish | Makes the surface shiny and fancy, and makes cleaning simple. |

| Coloring | Adds color for style and helps stop rust and wear. |

Getting help from experts makes it easier to pick the right surface finishing for each job. AFI Industrial Co., Ltd. provides skilled machining and finishing for 316 stainless steel. Think about where the part will be used, how it should look, and how tough it needs to be before you choose a surface treatment.

FAQ

Food-grade stainless steel often gets mechanical polishing or electropolishing. These treatments make the surface very smooth. Smooth surfaces help stop bacteria from sticking. They are also easy to clean. Many companies pick these finishes for food safety.

Passivation takes away free iron from the metal’s surface. This step makes a special chromium oxide layer. The layer helps stop rust and keeps the metal strong. It helps stainless steel last longer in tough places.

Yes, AFI Industrial Co., Ltd. can make custom surface finishes. Their team matches the finish to what each customer wants. They offer polishing, passivation, and coating. They check every part to make sure it meets high standards.

Mirror polishing makes stainless steel very smooth and shiny. Dirt and germs cannot stick well to this finish. Hospitals and kitchens use mirror polishing for easy cleaning. It also makes things look bright.

Sandblasting does not hurt stainless steel if done right. It takes off flaws and gives a soft, even look. Sandblasting also gets parts ready for paint or coating.

Bead blasting uses tiny beads to make a soft, even surface. Brushing uses rough brushes to make straight lines and texture. Both ways help the metal look better and hide small marks.

Think about how you will use the part and how it should look. Check if it needs to fight rust or be easy to clean. Ask experts like AFI Industrial Co., Ltd. for help picking the best treatment.

Colored finishes like PVD or chemical coloring last a long time. They do not fade, chip, or rust easily. Many designers use these finishes for style and strength.