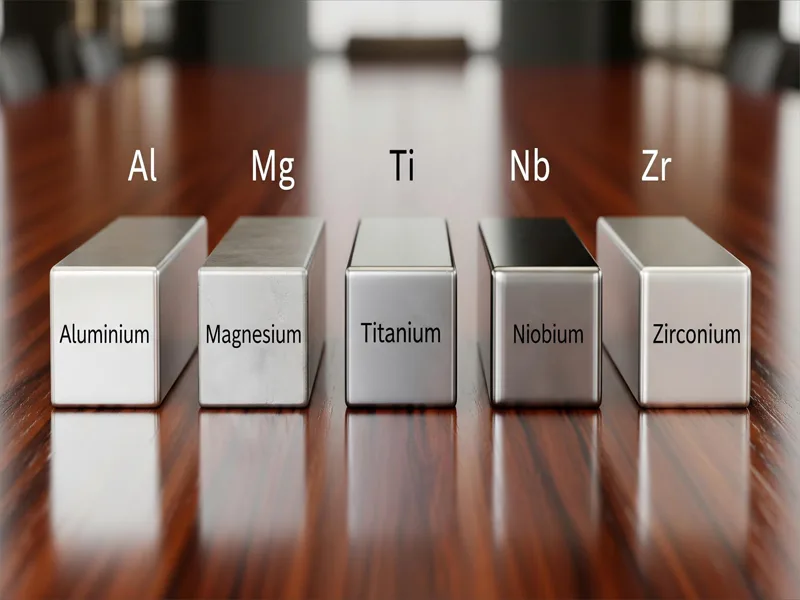

If you’re wondering what metals can be anodized, the primary options include aluminum, titanium, magnesium, and a few others. The choice of metal significantly affects the effectiveness of anodizing and the final quality of your product. For instance, aluminum is the most commonly anodized metal in industrial applications due to its cost-effectiveness and excellent anodizing properties. The table below highlights the usage distribution of these metals in anodized products:

| Metal | Percentage of Industrially Anodized Products |

|---|---|

| Aluminum | 67.2% |

| Titanium | Growing market |

| Magnesium | Small but increasing |

Understanding what metals can be anodized is crucial for selecting the right material to meet your requirements for durability, appearance, and specific engineering applications.

Key Takeaways

- Aluminum, titanium, magnesium, niobium, and zirconium can be anodized well. Anodizing makes a tough oxide layer. This layer keeps metals safe from rust and damage. It also lets you change the metal’s color. Aluminum is the most common metal for anodizing. It is strong, light, and comes in many colors. Titanium anodizing gives special colors without using dyes. It is good for medical and special uses. Magnesium needs careful work and extra steps to anodize. This helps it last longer and stay safe. Steel, stainless steel, copper, and some alloys do not anodize well. They need other ways to protect them, like painting or plating. Anodized metals are used in planes, cars, electronics, buildings, and medicine. They are chosen for their strength and good looks. Picking the right metal and anodizing process is important. It helps your product be strong, look good, and not cost too much.

Table of Contents

What Is Anodizing

Anodizing is a process that uses electricity to change metal surfaces. This process makes metals like aluminum and titanium stronger. It also helps protect them from getting damaged. To anodize, you put the metal in a special liquid called an electrolyte. Then, you connect the metal to electricity. This makes the surface react and form a protective oxide layer. How thick and strong this layer is depends on the voltage, the type of electrolyte, and how long you run the process. For example, anodizing aluminum can make a thin or thick layer. Anodizing titanium can even create nanotube shapes on the surface.

Anodizing Process Steps

Here are the main steps in the anodizing process:

- Cleaning: First, you clean the metal part. This step removes dirt, grease, and old oxide layers.

- Acid Pickling: Next, you dip the part in acid. This gets rid of any leftover dirt and gets the surface ready.

- Anodizing: Then, you put the clean metal in an electrolyte solution, like sulfuric acid. You connect it to a power source so it acts as the anode. The electric current makes oxygen ions react with the metal. This forms a new oxide layer.

- Coloring (Optional): If you want color, you can add dye to the anodized surface. The porous layer soaks up the dye, so you get many color choices.

- Sealing: Last, you seal the surface. This closes the pores in the oxide layer. It makes the metal more resistant to corrosion and wear.

Tip: The steps and chemicals can change depending on the metal you want to anodize. For example, anodizing titanium uses different voltages and electrolytes than aluminum.

Benefits of Anodizing

Anodizing gives metals several important benefits:

- Corrosion Resistance: The oxide layer keeps the metal safe from rust and chemicals. A thicker, even anodized layer helps aluminum stand up to acid rain and tough weather.

- Wear Resistance: Anodized metals last longer. The hard oxide layer lowers friction and wear. Tests show anodized aluminum loses less material over time than untreated metal.

- Color Options: You can pick from many colors by adding dyes. This makes anodized parts good for products where looks matter.

- Customizable Properties: You can change the process to control the oxide layer’s thickness and structure. This lets you choose the right type of anodizing for your needs, like more protection, a certain look, or special surface features.

Anodizing helps you make strong metal parts, last a long time, and look nice. You can use different types of anodizing to fit your project’s needs.

What Metals Can Be Anodized

Aluminum

Aluminum is the top metal for anodizing. You can find it in cars and phones. It is used a lot because it works well with anodizing. When you anodize aluminum, you make a strong, clear oxide layer. This layer keeps the metal safe from rust and damage. It also helps the metal last longer.

There are many kinds of aluminum alloys. The 6XXX and 5XXX series are best for anodizing. These alloys make a clear and tough oxide layer. The anodized layer is not just on top. It becomes part of the metal. This means it will not peel or chip off. That is why aluminum is good for things that must look nice and stay strong.

Here is a table that shows how aluminum compares to other metals in anodizing:

| Metal | Market Share / Industry Position | Key Applications |

|---|---|---|

| Aluminum | Largest market share; dominates anodizing | Automotive, construction, aerospace, electronics, consumer goods |

| Titanium | Smaller segment | Specialty applications |

| Magnesium | Smaller segment | Limited anodizing applications |

Note: Aluminum has a natural oxide layer that stops rust. Anodizing makes this layer thicker and stronger. You can also add color to anodized aluminum. That is why you see many colorful aluminum items.

Aluminum is light but strong. You can shape it in many ways. Anodizing does not change its size much. This is important for parts that must fit together. Anodizing also helps paint and glue stick better. If you want a metal that is easy to use and looks good, aluminum is a great pick.

Titanium

Titanium is another metal you can anodize. You might see anodized titanium in medical tools, jewelry, or fancy bike parts. Anodizing titanium makes a thin but strong oxide layer. This layer can be very thin or a bit thicker. The thickness changes the color you see. A thin layer can look blue. A thicker layer can look purple or bronze.

Anodized titanium is not just pretty. The oxide layer keeps the metal safe from rust. This is important for medical tools and implants. The layer also stops bad ions from leaving the metal. This makes it safer for the body.

| Anodizing Type | Thickness Range (Micrometers) | Corrosion Resistance | Hardness | Color Characteristics |

|---|---|---|---|---|

| Type 1 | 0.5 to 2.5 | Good | Low | Dull silver, dull color |

| Type 2 | 2.5 to 25 | Better | High | Gray, dull color |

| Type 3 | 25 to 100 | Best | Highest | Vibrant colors (green, blue, violet, purple, golden) |

📝 The color of anodized titanium depends on how thick the oxide layer is. You can get many colors without using dyes.

If you need a metal that is strong, light, and colorful, titanium is a smart choice. Anodizing makes it even better for special jobs.

Magnesium

Magnesium is a light metal that can be anodized, too. It is not as common as aluminum or titanium. But it is used in planes and electronics. Magnesium reacts a lot, so anodizing it is harder. You must control the heat, chemicals, and electricity very carefully.

Anodizing magnesium makes a hard layer that protects it. This layer helps stop rust, but it can have tiny holes. To make it stronger, you often add more treatments after anodizing. These steps help close the holes and make the metal last longer.

Tip: Magnesium parts must be very clean before anodizing. Dirt or old oxide can mess up the coating.

Magnesium is very light but still strong. It is good for parts that must not be heavy. If you work in planes or electronics, you might pick magnesium for its special features. Anodizing helps you get the best from this metal.

Niobium and Zirconium

When you think about what metals can be anodized, niobium and zirconium are special. These metals are not as common as aluminum. But they are very important in medicine and technology.

Zirconium is very helpful after anodizing. You can find anodized zirconium in many medical devices. Doctors use it for dental implants and joint replacements. It is also used in heart stents and surgery tools. The anodized layer does more than protect the metal. It makes the surface harder and helps the body accept the implant. This layer also stops bacteria from sticking. That lowers the chance of infection.

Some main benefits of anodized zirconium are:

- It resists corrosion, even inside the body.

- It lasts longer because it wears down less.

- The body accepts it well, so it is safe to use.

- You can make different colors for easy device ID.

- The oxide layer is hard, with a Mohs scale of 5-7.

Note: Anodizing zirconium can make many colors. This helps doctors and nurses tell devices apart during surgery.

Niobium is another metal that can be anodized. You do not see it much in daily life. But it is used for special things. The anodized layer gives niobium bright colors and protects it. People use anodized niobium for jewelry and decorations. It looks nice and has a strong surface.

If you work in medicine or high-tech design, think about these metals. Anodizing gives them special features that aluminum and other metals do not have.

Metals Unsuitable for Anodizing

Steel and Stainless Steel

You may think about anodizing steel or stainless steel. But this does not work well. Steel is made mostly of iron. When iron meets oxygen, it makes iron oxide. This is called rust. Rust is weak and falls off the metal. It does not protect steel at all. When rust falls off, new metal is exposed. That metal then rusts again. This keeps happening over and over. So, anodizing does not help steel.

Stainless steel is different from regular steel. It has chromium in it. Chromium makes a thin, invisible layer on the surface. This layer is called chromium oxide. It protects the metal from rust. If the layer gets scratched, it can fix itself. But anodizing does not make this layer thicker. The natural layer is already strong and stable. Anodizing does not make it better. Sometimes, anodizing can even make stainless steel rust more.

Note: Some special ways can make a thin oxide layer on steel or stainless steel. These use hot, strong chemicals. But these are not real anodizing. They are hard to do and cost a lot. Most companies do not use them.

Copper and Iron

Copper and iron are also not good for anodizing. If you try to anodize iron, it makes iron oxide. This is not stable and flakes off. The metal does not get real protection. Rust forms fast, and the surface stays weak.

Copper has its issues. It does not make a strong oxide layer when anodized. The layer that forms is patchy and can flake off. This leaves copper open to rust. Old copper turns green, but this is not a protective anodized layer.

- Iron oxide is weak and does not protect the metal.

- Rust on iron and steel makes holes and weak spots.

- Copper does not have a strong, natural oxide layer.

- Anodizing copper is rare and does not work well.

Other Metals

Some other metals are not good for anodizing either. Brass, carbon steel, and many alloys do not make the right kind of oxide layer. Instead of getting stronger, these metals can rust faster if you try to anodize them.

| Metal | Why Anodizing Fails |

|---|---|

| Steel | Makes weak, flaky rust; no protection |

| Copper | Makes patchy, weak oxide; poor rust defense |

| Stainless Steel | Already has a strong oxide layer; anodizing not needed |

| Brass | Does not make a smooth oxide layer |

| Carbon Steel | Rusts fast; oxide does not protect |

If you want to protect these metals, try painting, plating, or galvanizing. Anodizing works best for aluminum, titanium, magnesium, niobium, and zirconium.

Comparing Anodized Metals

Durability and Corrosion Resistance

When you look at anodized metals, you notice they look different. Some metals are much better at fighting rust and damage. Tests in labs show anodized aluminum is the best for protection. It makes a tough oxide layer that blocks water and chemicals. In a salt spray test, anodized aluminum stayed safe for 96 hours. Only the edges had a little rust, but the rest was fine.

Anodized titanium also fights rust, but not as well as aluminum. Its protection lasts from 8 to 24 hours. This depends on how many tiny holes are in the surface. If there are lots of holes, salt can get in and make pits. You must control the process to get the best results.

Magnesium is very light, but it does not stop rust well. Its oxide layer has more holes and is not as strong. Without extra coatings, magnesium can rust fast. You often need to add more layers to help it last longer.

| Material/Coating | Corrosion Resistance (Salt Spray Test) | Durability/Observations |

|---|---|---|

| Anodized Aluminum | Up to 96 hours | Minor corrosion at edges; strong, dense oxide layer |

| Anodized Titanium | 8-24 hours | High porosity can lead to pitting; needs careful process control |

| Anodized Magnesium | Low | Porous oxide layer; needs extra coatings for better protection |

Tip: For the best rust protection, pick anodized aluminum. Titanium is good for special jobs if you control the process.

Appearance and Color Options

Anodizing changes how metals look and feel. You can choose from many colors and finishes, but it depends on the metal.

| Metal Type | Appearance Characteristics | Color Options and Notes |

|---|---|---|

| Anodized Aluminum | Metallic look, smooth finish | Many colors: clear, black, blue, red, green, gold, and custom shades. Best color variety. |

| Anodized Titanium | Silver-gray, shiny, biocompatible | Unique colors: silver, bronze, purple, blue, gold, green, and more. Colors depend on oxide thickness. |

| Anodized Magnesium | Silvery-white, less shiny | Fewer color options. Surface can be improved with extra coatings. Natural color is silvery-white. |

Aluminum gives you the most color choices. You can match almost any design. Titanium has special colors that change with the oxide layer’s thickness. These colors do not need dyes. Magnesium looks bright and clean, but you get fewer colors. You can make it look better with extra treatments.

Note: The oxide layer’s thickness and shape change how the metal takes color. Aluminum soaks up dyes best, so its colors are brighter and more even.

Cost and Industry Use

You should think about price and where each metal works best. Aluminum is the top choice because it is cheap and easy to use. It makes up about 70% of the market. You see anodized aluminum in cars, buildings, and electronics.

- Titanium costs more to anodize, so it is about 15% of the market. You find it in medical tools and airplane parts where special features are needed.

- Magnesium is lighter but not used as much, with about 10% of the market. It is found in electronics and some car parts.

- Zinc and other metals are used less.

The aerospace industry uses anodizing the most, about 35% of all uses. Building and computer hardware also use a lot of anodized parts. Companies like anodizing because it is safe for the environment and meets strict rules in North America and Europe.

If you want a strong, colorful, and low-cost finish, pick aluminum. For high-tech or medical jobs, titanium or magnesium may be better, but they cost more.

Applications of Anodizing

Aerospace and Automotive

Anodized metals are used a lot in planes and cars. Engineers pick anodized aluminum because it does not rust easily. It can handle rough weather and hard use. You see it in airplane panels and strong parts. Even space stations use anodized aluminum for trusses and handrails. These parts help control heat and reflect light. The gold color on the handrails makes them easy to see. This keeps astronauts safe.

In cars, anodized aluminum is in trim, wheels, and engine covers. These parts look nice and last a long time. The anodized layer stops scratches and damage from salt or rain. Because it is light, it helps cars and planes use less fuel. This saves money and makes them work better. Car makers use anodized parts for style and strength.

- Airplane panels and strong frames

- Space station handrails and anchors

- Car trim, wheels, and engine covers

- Name plates and control panels

Anodized aluminum keeps its color and shine for years, even in tough places.

Electronics and Consumer Goods

You use anodized products every day. Anodizing makes electronics and home items stronger. The process makes the metal surface hard. This helps your devices resist scratches and damage. The oxide layer does not peel off like paint. You do not need to fix it often.

Anodized surfaces keep out water and salt. Your devices last longer, even in wet places. The color stays bright because it is inside the oxide layer. You can get phones, laptops, and kitchen tools in many colors. The finish looks smooth and feels nice.

- Strong phone and laptop cases

- Colorful kitchen tools

- Camera bodies that do not wear out fast

- Audio equipment that lasts a long time

Anodizing also helps spread heat in electronics. The oxide layer moves heat away. This keeps your devices cool and safe.

Construction and Architecture

Modern buildings use a lot of anodized aluminum. Architects like it because it looks clean and is strong. The metal shines in rain, sun, or salty air. You see it on building walls, windows, and doors. The anodized layer stops rust and damage. Buildings look new for a long time.

Anodized aluminum comes in many finishes. You can pick satin, matte, or shiny looks. There are many colors to match any style. Builders use it for new buildings and upgrades. The metal is light but strong. It adds style without making things heavy.

- Building walls and outside panels

- Window and door frames

- Decorative panels and railings

- Custom laser-cut designs

Anodized aluminum is easy to clean and needs little care. It is also good for the environment because it can be recycled.

Medical Devices

When you look at medical devices, safety is very important. These devices must also work well every time. Anodized metals help make sure of this. You often see anodized aluminum and titanium in hospital tools and implants. These metals are used for many reasons.

Why do medical device makers use anodized metals?

- Enhanced Durability and Wear Resistance

Anodizing makes a hard layer on the metal. This layer keeps tools safe from scratches and dents. It helps them stay strong after many uses. - Corrosion Resistance

Medical devices get cleaned with strong chemicals. The anodized layer stops rust and corrosion. This means your tools last longer and stay safe. - Biocompatibility

Anodized aluminum and titanium are safe for the body. They do not react with skin or tissue. This is why they are good for implants and tools. - Customization and Aesthetic Appeal

You can add color to anodized surfaces. This helps doctors find the right tool fast. Color coding also helps stop mistakes in busy hospitals. - Hygiene and Sterilization

The smooth surface of anodized metals does not let stains or germs stick. You can clean and sterilize these tools easily. This helps stop infections in hospitals. - Lightweight yet Strong

Anodized aluminum is light but still strong. This makes it easy to move and use medical devices. It helps hospital staff do their jobs better.

Tip: Anodized coatings help meet FDA rules. You can mark tools with numbers or colors for tracking.

You see anodized metals in many medical items:

- Surgical tools

- Implants for bones

- Dental tools

- Hospital beds and carts

- Machines for tests

AFI Industrial Co., Ltd. uses special anodizing methods for medical devices. Their process gives each tool a strong and even finish. You get products that last longer and look good. They also help keep patients safe.

When you pick anodized metals for medical devices, you choose safety and strength. These features help you give better care and meet high standards in healthcare.

Choosing the Right Metal

Performance Considerations

When you pick a metal for anodizing, think about how it will work. Each metal and alloy reacts in its own way to anodizing. You want your choice to fit your product’s needs for strength, toughness, and looks.

- Alloy Selection: Some aluminum alloys, like 7075, 7050, and 7049, are best for strong parts. These alloys make tough surfaces after anodizing. If your part must handle heavy use or rough places, pick a strong alloy.

- Corrosion and Wear Resistance: Anodizing makes a hard layer that helps stop rust and wear. This is important for planes, military gear, and outdoor things. You can make this layer better by picking the right sealing. Boiling water sealing is easy and cheap. Dichromate sealing protects well but may hurt the environment. Nickel acetate and cold nickel fluoride sealings keep color and work well outside.

- Coating Thickness: Thicker coatings protect more but cost extra. You should balance how much protection you need with your budget.

- Dimensional Changes: Anodizing makes the surface thicker and can make holes smaller. You need to plan for these changes when you design your part.

- Electrical Conductivity: The anodized layer stops electricity. If you need some spots to conduct, you must cover them before anodizing.

- Color and Appearance: The alloy, anodizing type, and dyeing method change your color choices. You can pick natural, black, gold, or special colors.

Tip: Always match the sealing and coating thickness to where your product will be used. Outdoor parts need strong sealing to last longer.

Design and Manufacturing Factors

Your design and how you make your part also help you pick the right metal for anodizing. Different anodizing types give different results. You need to choose the best process for your product.

| Anodizing Type | Best For | Key Benefits |

|---|---|---|

| Chromic Acid | Aerospace, bonding | Thin layer, good for adhesives |

| Sulfuric Acid | General use, consumer products | Cost-effective, strong, versatile |

| Hardcoat Anodizing | Heavy wear, insulation | Thick, durable, electrical barrier |

- Alloy Series: Some alloys, like the 6xxx series, anodize well and look clear and strong. Others, like the 2xxx or 4xxx series, may need special care or are not the best for anodizing.

- Surface Preparation: Clean, smooth parts give the best results. Handle parts gently and do not touch them with tape or fingers before anodizing.

- Part Size and Complexity: Big or tricky parts may need special tools or extra steps. This can change the price and how long it takes.

- Industry Standards: Some jobs, like planes and military, have strict rules like MIL-A-8625. Aluminum meets these rules and is used a lot for this reason.

If you want the best results, talk to experts like AFI Industrial Co., Ltd. Their team can help you pick the right metal, alloy, and anodizing process for your project. They know how to match your needs for performance, looks, and cost.

Picking the right metal for anodizing helps your product last longer, look better, and meet your industry’s needs. Always think about both how it works and how you make it before you decide.

Picking the right metal for anodizing changes how your product works, lasts, and looks. You make your product better when you pick the right metal for what you need.

- Think about how the size may change and design your part so the coating is even.

- Pick the anodizing type and color that fits how tough and good-looking you want your product to be.

- Talk to anodizing experts so you do not make expensive mistakes and your project goes well.

Knowing which metals work for anodizing helps you make products that follow industry rules and do well in real life.

FAQ

Aluminum, titanium, and magnesium are the easiest to anodize. These metals make strong oxide layers during the process. Aluminum is used the most. It gives great color, strength, and protection.

Steel and copper do not make stable oxide layers when anodized. Steel makes rust that falls off. Copper makes a weak and uneven layer. These metals do not get good protection like aluminum or titanium.

You can anodize small aluminum parts at home if you have the right safety gear and chemicals. Always follow safety steps. For the best results, it is better to use a professional service like AFI Industrial Co., Ltd.

Anodizing puts a thin oxide layer on the surface. This layer is about 5 to 25 micrometers thick. The part may get a little bigger, but the change is very small. Most of the time, it does not change how parts fit.

Anodized metal can last for many years. The oxide layer keeps out rust, scratches, and fading. Even if you use it outside or in rough places, it keeps its color and strength for a long time.

Yes, you can add lots of colors to anodized aluminum and titanium. The color comes from dyes or changes in the oxide layer. You get bright colors that do not peel or fade.

Anodized aluminum and titanium are safe for food and medical tools. The oxide layer does not react with food or skin. Many kitchen and medical items use anodized surfaces because they are safe and easy to clean.

Aerospace, automotive, electronics, construction, and medical fields use anodized metals the most. These industries pick anodized parts because they are strong, light, and keep their color.