To understand how to prevent CNC machined copper rust parts, there are several effective methods to keep copper components safe from corrosion. Common surface treatments include nickel plating, electroless nickel, chrome plating, passivation, lacquering, anodizing, and polishing. These treatments play a crucial role in stopping corrosion. Additionally, controlling the environment and performing regular maintenance are essential steps to protect copper. Factors like moisture, salty water, heat, and UV rays can damage the patina layer and cause copper to oxidize. Choosing the right surface treatment tailored to your copper CNC machining project is key to preventing rust and ensuring durability.

Key Takeaways

- Pick the best surface treatment, like nickel plating or electroless nickel. This helps protect copper parts from corrosion and makes them last longer. Keep copper parts clean and dry by washing and polishing them often. This stops dirt and water from causing harm. Think about where you will use the copper parts. Tough places like saltwater or heat need stronger coatings for more protection. Check copper parts often for corrosion or damage. Store them in cool, dry places to stop rust and wear. Use coatings like lacquering or polyurethane on outdoor copper parts. These coatings protect them from the sun, rain, and oxidation.

Table of Contents

Copper Rust Basics

Why Copper Rust

Copper is often used for CNC-machined custom copper parts. It does not rust as fast as iron. But copper can still corrode in many places. When copper comes into contact with air and water, it reacts with oxygen. This makes copper oxide, which looks green on the surface. The main reaction is:

2Cu + O2 → 2CuO

You can see this green color on old statues or roofs. In factories, other chemicals can make corrosion happen faster. For example:

- Acids like sulfuric acid or hydrochloric acid hurt copper.

- Alkalis such as ammonia or sodium hydroxide also cause harm.

- Salts, especially chlorides and sulfates, speed up corrosion.

If copper is next to other metals and water is present, galvanic corrosion can happen. Here, copper acts as the anode and corrodes more quickly. High heat, pollution, and saltwater make these reactions go faster.

Tip: Keep copper cnc machining parts dry and clean to slow down corrosion.

Effects on CNC-Machined Custom Copper Parts

Corrosion can damage CNC-machined custom copper parts in many ways. Water and dirt can get stuck in small cracks or grooves. These places are where corrosion starts. Pollutants like acidic vapors and chloride ions make things worse. Over time, you may see pits, color changes, or even holes in your CNC-machined metal parts.

If you do not protect your custom CNC-machined copper components, they can get weak. This damage makes them last less time and work worse. You might also see that electrical conductivity drops, which is a big problem for copper CNC machining.

To keep your CNC-machined metal parts safe, use surface treatments like coatings or lacquers. These layers block water and dirt from reaching the copper. Cleaning and checking your parts often helps you find corrosion early before it gets bad.

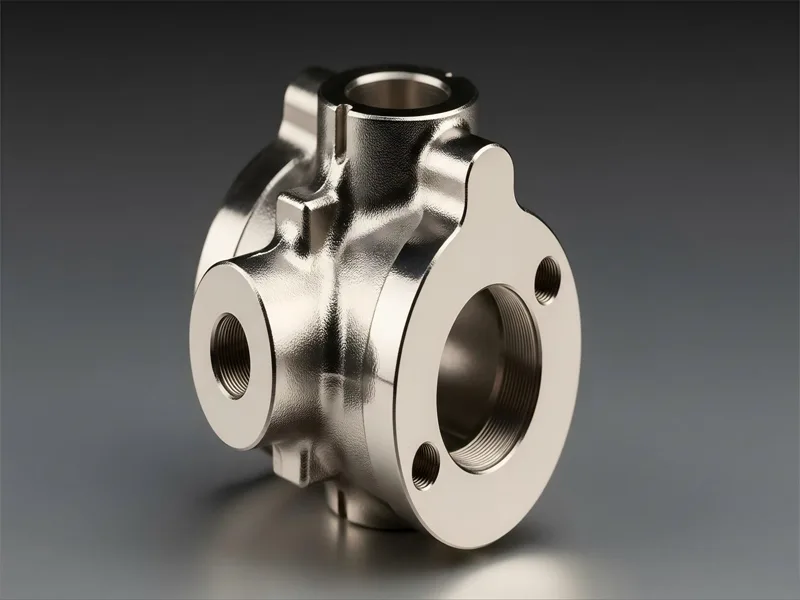

Surface Treatments for Corrosion Resistance

If you want to stop corrosion on CNC-machined copper parts, you need to pick the right surface treatment. Each treatment helps in different ways. Some make copper last longer. Others make it look better. Let’s check out the best ways to treat copper surfaces.

Nickel and Chrome Plating

Nickel plating and chrome plating are good for stopping corrosion. These coatings go on the copper using electroplating. Nickel plating makes a strong layer. This layer keeps out water and salt. It is great for CNC parts in tough places. Chrome plating gives a shiny look and makes copper stronger. If you use both nickel and chrome, you get good protection and a nice finish.

Here is a table that shows how much these coatings cost and how well they work:

| Plating Type | Cost Range (per sq. ft.) | Corrosion Resistance & Effectiveness |

|---|---|---|

| Electroless Nickel | $7 – $20 | Superior corrosion resistance, uniform coating, durable |

| Nickel Chrome Plating | $20 – $50 | Combines nickel’s corrosion resistance with chrome’s finish; more expensive but adds durability and aesthetic appeal |

| Chrome Plating | N/A | Provides corrosion resistance and decorative finish; specific cost not detailed |

Nickel plating is strong and not too expensive. It works for most CNC copper parts. Chrome plating, when put over nickel, gives even better protection and a shiny look. Use chrome plating if you want your part to look good and last long.

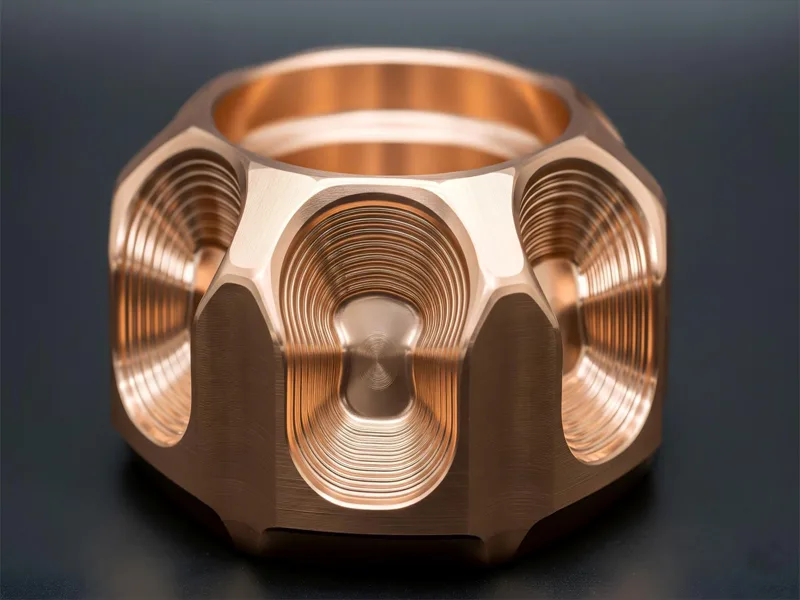

Electroless Nickel and Tin Coatings

Electroless nickel coating does not need electricity. It uses a chemical bath to cover the copper. This method works well for small or tricky shapes. The coating is usually 0.001″ to 0.002″ thick. This even layer helps stop corrosion and makes copper harder.

Tin coating is another choice. It is used for electronics and food-safe parts. Tin is safe to touch food. Tin does not protect as well as nickel, but it still helps. You often see tin on wires and connectors.

Tip: Pick electroless nickel if your cnc part has a complex shape and needs strong protection.

Passivation and Anodizing

The passivation process is to form a thin film on the copper surface. This film slows down corrosion. It works best where there is a lot of moisture. Some new passivation methods use lasers. These can help copper resist heat and last longer. But normal passivation is better for stainless steel. It may not work as well for copper in very wet places.

Anodizing is common for metals like aluminum. But it does not work for copper. Copper cannot be anodized. Do not use this method for copper parts.

Lacquering and Polishing

Lacquering is an easy way to protect copper. You put a clear coat on the surface. This keeps out air, water, and dirt. Lacquering makes copper shiny. But lacquer does not last long outside. Sun and rain can make it crack in a few months. Temperature changes make lacquer break easily. It is not good for long-term outdoor use.

Polishing cleans off dirt and old layers from copper. It makes copper look bright and smooth. Polishing is good for regular care. But it does not protect copper for a long time. For best results, polish first and then add a coating.

Note: For outdoor copper, use polyurethane instead of lacquer. Polyurethane stays strong and protects copper for many years.

Summary Table: Surface Treatments for CNC Machined Copper Parts

| Surface Treatment | Main Benefit | Best Use Case |

|---|---|---|

| Nickel Plating | Exceptional corrosion resistance | Harsh environments, complex cnc parts |

| Chrome Plating | Decorative and durable finish | Visible parts needing both looks and protection |

| Electroless Nickel | Uniform coating, high durability | Small or complex CNC-machined copper parts |

| Tin Coating | Food-safe, basic protection | Electronics, food industry |

| Passivation | Reduces oxidation | Indoor parts, moderate humidity |

| Lacquering | Easy, clear protection | Indoor decorative copper, short-term outdoor |

| Polishing | Shiny, clean surface | Maintenance, combined with other treatments |

Each surface treatment has its good points. Pick the one that fits your CNC-machined copper part and where you will use it. This will help your copper parts last longer and stay strong.

How to Prevent CNC Machined Copper Rust Parts

Choosing the Right Treatment

To stop CNC-machined copper rust parts, pick the best surface treatment. The right choice depends on your copper part’s grade, shape, and use. Some copper grades are easier to machine and conduct electricity better. This can change how well a coating sticks and how long it lasts. If your CNC part has a tricky shape, electroless nickel or e-coating is a good choice. These coatings cover every part of the surface evenly.

Tip: Make sure your cnc copper part is smooth before you add any coating. A smooth surface helps the coating stick and gives better rust protection.

Think about what your copper part needs to do. If you need it to carry electricity well, silver or gold plating is helpful. For most jobs, nickel plating is strong against corrosion and keeps rust away. If you want to stop oxidation and keep copper shiny, passivation or lacquering can help. But these do not work as well in very tough places.

Application and Environment Factors

Where you use your CNC-machined copper part matters a lot. In places near the ocean, there is more humidity and salt. This makes corrosion and oxidation happen faster. You need a coating that can handle these hard conditions.

- The copper grade changes how well it fights corrosion.

- Humidity and salt in marine areas need strong coatings like nickel or gold plating.

- Thick and even coatings last longer and protect better.

- For hot places, special passivation layers like Si–Cu–O film can stop oxidation above 400°C and keep copper strong.

- In acidic or alkaline places, e-coating gives full protection and works well for tricky CNC shapes.

Here is a table to help you pick the right treatment for your environment:

| Environment | Best Surface Treatment | Key Benefit |

|---|---|---|

| Marine (Salt, Humidity) | Nickel/Gold Plating | Strong corrosion and oxidation resistance |

| High Temperature | Si–Cu–O Passivation Layer | Prevents oxidation, keeps conductivity |

| Acidic/Alkaline | E-Coating | Full chemical barrier, rust proof |

| Indoor/Low Stress | Lacquering, Passivation | Keeps appearance, easy to apply |

If you use these tips for stopping CNC-machined copper rust parts, your CNC copper parts will last longer, stay strong, and look good.

Maintenance for CNC-Machined Custom Copper Parts

Cleaning and Handling

You need to keep CNC-machined custom copper parts clean to prevent corrosion and keep them working well. Dust, grease, and fingerprints can speed up tarnishing on copper. Start by washing your copper parts with warm, soapy water. This removes most dirt and oil. For tougher stains, you can make a cleaning paste with lemon juice and salt. Lemon juice breaks down tarnish, and salt acts as a gentle scrub. Rub the paste on the copper in small circles. If stains remain, let the paste sit for a few minutes before scrubbing again. Rinse the part with warm water and dry it right away with a lint-free towel. This stops water spots from forming.

Specialized cleaners like AquaVantage® 815 GD work well for copper alloys. These cleaners use a safe pH and low temperature to avoid damaging the surface. Always rinse with cool water after using these cleaners. This helps prevent flash tarnish and keeps your CNC parts looking bright. You can also use homemade polishes, such as lemon juice mixed with cream of tartar, for gentle cleaning. For valuable or very dirty parts, consider professional cleaning.

Tip: Always polish copper in the direction of the grain. This keeps the surface smooth and shiny.

Inspection and Storage

Regular inspection is a key part of maintenance for CNC-machined custom copper parts. Look for signs of corrosion, such as green spots, pits, or dull areas. If you see any, clean the part right away. Untreated copper parts need more frequent checks because they form an oxide layer that can lower conductivity. You may need to use physical or chemical cleaning to remove this layer.

Surface-treated copper parts, like those with nickel or tin plating, need less maintenance. These coatings protect against oxidation and wear, so you do not have to clean them as often. Still, check them for scratches or damage that could let moisture reach the copper.

Store your CNC parts in a dry, cool place. Use airtight containers or bags with silica gel to keep out moisture. Avoid stacking heavy items on top of copper parts to prevent dents or scratches.

- For bare copper, inspect and clean before each use.

- For treated parts, check for coating damage and clean only when needed.

Note: Good storage and regular inspection help your cnc machined custom copper parts last longer and work better.

You can keep your CNC-machined copper parts safe from corrosion by picking the right surface treatment and taking care of them. Surface treatments like electroplating and polishing help stop corrosion and make copper look nice. Experts say silver and nickel plating work best for copper. Cleaning and checking your parts often helps them last longer. Do not use finishes that do not fit your environment, or your parts may get damaged fast. If you follow these steps, you can save money and keep your copper parts strong.

- Key strategies include:

- Picking a surface treatment that fits how you use your copper part

- Adding protective coatings to help stop corrosion

- Cleaning and checking your parts often

Remember, making good choices now can help you avoid expensive corrosion problems later.

FAQ

You should use a surface treatment like nickel plating or electroless nickel. These coatings create a barrier that keeps out moisture and air. This helps your copper parts last longer and look better.

You should clean copper parts every few months. If you see dirt or fingerprints, clean them right away. Regular cleaning keeps the surface shiny and helps you spot problems early.

Yes, you can use copper parts outdoors. You need to add a strong coating, like polyurethane or nickel plating. This protects the copper from rain, sun, and corrosion.

Avoid damp places and direct sunlight. Store copper parts in a dry, cool area. Use airtight containers or bags with silica gel to keep out moisture.