Nylon Materials made a big difference when scientists first used them in toothbrush bristles and women’s stockings in the 1930s. Today, factories and designers pick nylon because it is strong, bends easily, and does not get damaged by many chemicals. Many industries use nylon because it works well under pressure. One nylon fiber can stretch up to 25% of its length and not break. Knowing what makes nylon special helps engineers and buyers make good choices.

Table of Contents

Key Takeaways

- Nylon is a strong and bendy material. People use it in cars, clothes, and electronics. It is also used in many other things.

- There are different kinds of nylon. Each type has special features. Some can handle heat. Some are very strong. Others keep water out.

- If you add glass or carbon fibers, nylon gets even stronger. It also becomes stiffer. This helps nylon work well for hard jobs.

- Nylon can soak up water from the air. So, it must be dried before use. It also needs to be stored the right way.

- Nylon does not get ruined by most chemicals. But strong acids and halogens can hurt it.

- Nylon parts last a long time. They do not wear out fast. They can take hits and heat better than many other plastics.

- Recycling nylon helps the planet. New smart nylons are also better for the earth. These changes make nylon more eco-friendly.

- Good design is important for nylon parts. Careful work stops problems like bending or breaking.

Nylon Materials Overview

Definition

Nylon Materials are man-made polymers called polyamides. Scientists make them by joining small molecules into long chains. These chains help nylon stay strong and bend easily. Factories use nylon in lots of things because it does not wear out fast and can handle heavy use. Nylon Materials often take the place of metals and natural fibers in many products for factories and people.

History

The story of nylon started when people wanted new man-made fibers. DuPont researchers began working on polymers in 1927. Wallace Carothers led the team and looked for materials that could be used in factories.

Key milestones in nylon’s development:

- DuPont started polymer research in 1927, beginning the search for new fibers.

- Wallace Carothers joined DuPont to lead the research group.

- On February 28, 1935, Carothers made the first nylon polymer, called nylon 6,6.

- Paul Schlack at IG Farben made nylon 6 in 1938.

- DuPont told the public about nylon in 1938, before the 1939 New York World’s Fair.

- The first time nylon was sold was in toothbrush bristles in 1938.

- Nylon stockings went on sale in 1940, with 64 million pairs sold in the first year.

- The first nylon factory opened in Seaford, Delaware, in 1939.

- Another factory started in Martinsville, Virginia, in 1941.

- During World War II, factories used nylon mostly for military things like parachutes and cords.

Nylon Materials soon became important for everyday life and work. Their strength and many uses made them a favorite for new products.

Types

Nylon comes in different types, and each one has special features. The way their molecules are put together changes how they work in different places.

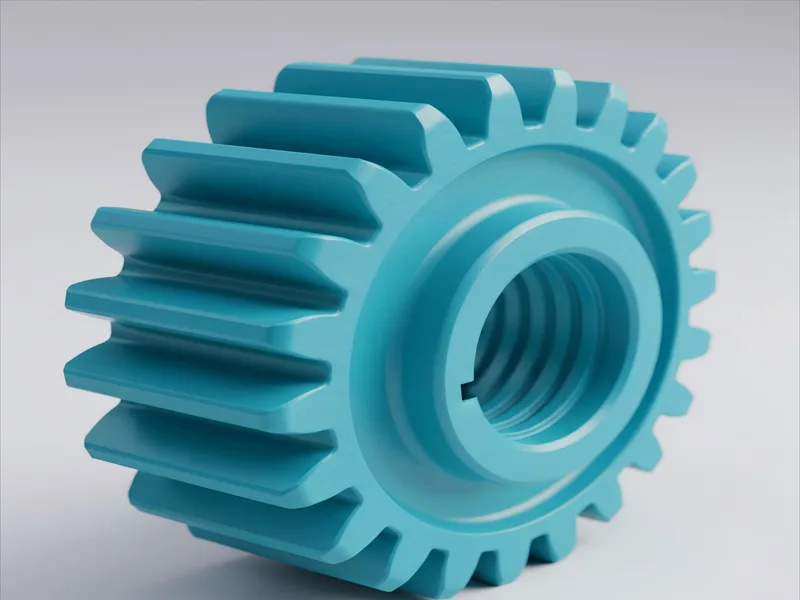

PA6

PA6, or Nylon 6, is made from caprolactam monomers. It has a structure that mixes strength, bending, and soaking up water. Factories use PA6 for gears, clothes, and car parts because it is strong and easy to shape.

PA66

PA66, or Nylon 6/6, is made from adipic acid and hexamethylenediamine. Its even and packed structure makes it stronger, stiffer, and better with heat than PA6. PA66 is good for things that need to last, like engine parts and electric connectors.

PA12

PA12 uses dodecanedioic acid, which gives it longer chains. This makes it great at keeping out water and holding its shape. PA12 is used in car fuel lines, air tubes, and cable covers.

PPA

PPA means polyphthalamide. It is a strong nylon with special rings in its structure. PPA can handle high heat and chemicals very well. Engineers pick PPA for tough jobs like car engine parts and electronics.

Modified Nylons

Modified nylons are blends or types with extra stuff added. Makers mix in glass fibers, minerals, or other polymers to make them stronger, stiffer, or harder to break. These new kinds let Nylon Materials be used in even more things for factories and people.

Tip: Pick the nylon type that fits what you need, like strength, bending, or keeping out water and chemicals.

Properties

Strength

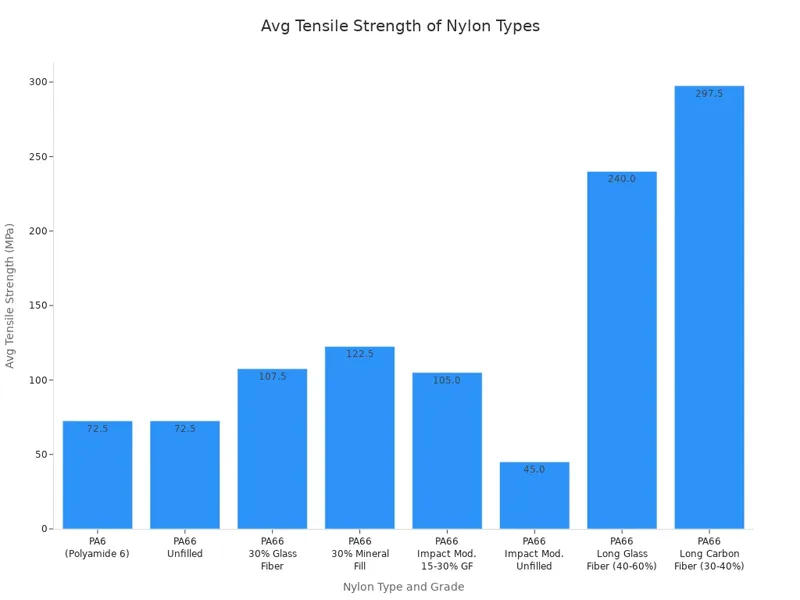

Strength is one of the most important things about Nylon Materials. Many engineers pick nylon because it can hold heavy things without breaking. The strength depends on the type of nylon and what is mixed in. PA6 and PA66 are both strong and can stretch without snapping. If glass fibers or minerals are added, nylon gets even stronger.

Here is a table that shows how strong different nylon types and grades are:

| Nylon Type and Grade | Tensile Strength Range (MPa) |

|---|---|

| PA6 (Polyamide 6) | 50.0 – 95.0 |

| PA66 (Polyamide 6-6) Unfilled | 50.0 – 95.0 |

| PA66 with 30% Glass Fiber | 90.0 – 125.0 |

| PA66 with 30% Mineral Fill | 45.0 – 200.0 |

| PA66 Impact Modified with 15-30% Glass Fiber | 90.0 – 120.0 |

| PA66 Impact Modified Unfilled | 40.0 – 50.0 |

| PA66 with Long Glass Fiber (40-60% filler) | 210.0 – 270.0 |

| PA66 with Long Carbon Fiber (30-40% filler) | 290.0 – 305.0 |

Note: When glass or carbon fibers are mixed into nylon, it gets much stronger than normal nylon. This helps make parts that last longer or hold more weight.

Stiffness

Stiffness means how hard it is to bend or stretch something. Nylon Materials are stiff, so they work well for gears and car parts. The type of nylon and what is added can change how stiff it is. Glass fibers make nylon even stiffer and harder to bend.

When you compare nylon to other plastics, it is stronger and handles heat better than ABS. Nylon bends more easily, but ABS is harder and not as strong. Polycarbonate can be even stiffer and stronger than nylon, depending on the kind.

| Property/Feature | Nylon | ABS |

|---|---|---|

| Tensile Strength (MPa) | 70 – 100 | 30 – 45 |

| Flexibility | More flexible | More rigid |

| Heat Resistance | Higher heat deflection temp | Lower heat deflection temp |

| Strength & Wear | Superior strength and wear resistance | Good overall strength and toughness |

Tip: If you need a part to keep its shape under pressure, engineers often use nylon with glass fibers.

Impact Resistance

Impact resistance shows how well a material can take a hit or shock without breaking. Nylon Materials are good at this, especially compared to many other plastics. This makes nylon a smart pick for things that might get dropped or bumped.

Tests like ISO 180 and ASTM D256 are used to check impact resistance. For example, regular PA6/6 nylon usually gets about 5.5 kJ/m² in the ISO 180 test and about 1.0 ft-lb/in in the ASTM D256 test.

| Material | Test Method | Typical Impact Resistance Value |

|---|---|---|

| Nylon PA6/6 (unfilled) | ISO 180 (notched) | Approximately 5.5 kJ/m² |

| Nylon PA6/6 (unfilled) | ASTM D256 (notched) | Approximately 1.0 ft-lb/in |

Note: Impact resistance can change if the temperature or humidity changes, or if the nylon is made in a different way. Nylon with special impact modifiers or fibers can handle even tougher situations.

Chemical Resistance

Nylon Materials can handle many chemicals, but not every kind. The type and strength of a chemical can change how nylon acts. Nylon does well with many bases and organic solvents. Strong acids, halogens, and some organic acids can hurt nylon fast. The table below shows how nylon reacts to different chemicals:

| Chemical Type | Specific Chemicals / Conditions | Resistance Summary |

|---|---|---|

| Acids | Concentrated hydrochloric, nitric, phosphoric, sulfuric acids; organic acids | Poor resistance; nylon dissolves or partially dissolves; not recommended |

| Bases | Potassium hydroxide (5-10%), sodium hydroxide (1-10%) at room temperature | Good to excellent resistance; higher temperatures can cause some damage |

| Halogens | Bromine, chlorine | Strong attack; not recommended |

| Organic Solvents | Alcohols, hydrocarbons, ketones, esters | Mostly good to excellent resistance; some temporary loss of stiffness in alcohols |

| Phenol Compounds | Phenol, chlorophenols, cresol, xylenols | Dissolves nylon; not recommended |

Note: Always check what chemicals are around before picking nylon for a part. Some chemicals can make nylon weak or break it, especially if they are strong or hot.

Thermal Stability

Nylon can take more heat than most other plastics. Most regular nylon types work from about 210°F to 250°F for a long time. The exact heat it can take depends on the nylon type and if it has glass fibers. Some special nylons can handle even hotter places. The table below shows the highest temperatures for common nylon types:

| Nylon Type | Max Continuous Use Temperature (°C) | Max Continuous Use Temperature (°F) |

|---|---|---|

| PA 6 | 80–120 | 176–248 |

| PA 66 | 80–150 | 176–302 |

| PA 46 | 110–160 | 230–320 |

Nylons with glass fibers can take more heat than plain nylon. Designers use these numbers to make sure nylon parts last in hot places.

Moisture Absorption

Nylon takes in water from the air. This is called hygroscopicity. At room temperature, nylon can soak up about 1.5% to 2% of its weight in water. If nylon sits in water or very wet air, it can take in up to 5% to 8%. When nylon gets wet, it swells and grows about 0.5% to 0.6% bigger. This can change how parts fit together.

Water changes nylon’s properties. Dry nylon is strong and stiff but can snap easily. Wet nylon is tougher and less likely to break, but it gets softer and bends more. The glass transition temperature drops from about 65–70°C to around 10°C when nylon is wet. This means nylon feels softer and bends easier.

Tip: Glass fibers help nylon take in less water. Still, all nylon types change size and strength when wet. Engineers must think about this when making parts that need to stay the same size or shape.

Nylon Materials must be dried before molding. If nylon is too wet, bubbles or weak spots can show up in the finished part. Different nylons soak up different amounts of water. For example, PA12 takes in less water than PA6, so it stays more stable when wet.

Electrical Insulation

Nylon Materials are good at stopping electricity from passing through. Engineers use nylon in many electrical parts for this reason. Dielectric strength tells us how much voltage a material can take before it fails. Most plastics, like nylon, have dielectric strengths from 10 to 30 kV/mm. This means nylon can block electricity in normal situations.

| Polymer Variant | Dielectric Strength Range (kV/mm) |

|---|---|

| Nylon (PA 66) | 11.8 – 30 |

| Nylon (PA 66) with 30% Glass Fiber | 25 |

| Nylon (PA 66) with 30% Mineral Fill | 25 – 30 |

| Nylon (PA 66) Impact Modified | 18 – 90 |

| Nylon (PA 66) with Carbon Fiber | 1.3 |

The type of nylon and what is added can change its dielectric strength. Glass fibers help nylon keep its insulating power. Carbon fibers make nylon less able to block electricity. Heat, stress, and how the part is made also matter. Nylon does not insulate as well as some special plastics. Still, it works for most electrical jobs.

Note: Nylon insulates well in many devices. But if the part gets very hot or faces strong forces, it may not block electricity as well.

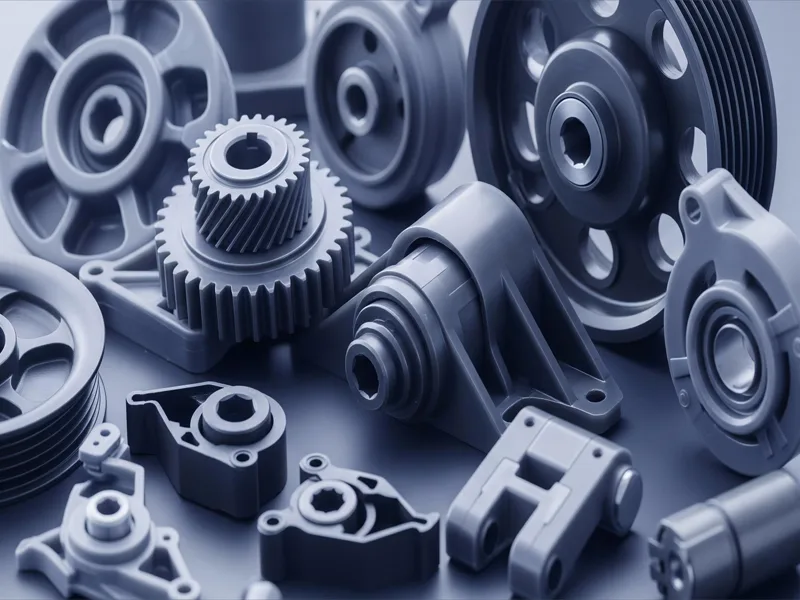

Wear Resistance

Wear resistance means how well something stands up to rubbing or sliding. Nylon Materials are great at this. That is why many moving parts are made from nylon. Factories use nylon for gears, bushings, and bearings because it lasts a long time.

| Material | Specific Wear Rate (m³/N·m × 10⁻¹⁵) |

|---|---|

| Acetal | 2.0 |

| Nylon 6/6 | 3.0 |

Nylon has a low wear rate, almost like acetal. Both work well when they touch metal. Nylon has a smooth surface, so it slides easily and does not need much oil.

- Nylon can act as a self-lubricating material.

- It helps machines make less noise.

- Nylon parts do not need much care.

- It keeps working well after many uses.

Nylon’s wear resistance is helpful in cars, machines, and home items. It can take heavy loads and keeps its shape. Metals may last longer sometimes, but nylon is lighter and quieter for many uses.

Tip: Pick nylon for parts that move or rub together. It helps machines work better and last longer.

Nylon Materials Comparison

PA6 vs PA66

PA6 and PA66 are two popular types of nylon. Both are strong, but they are not the same. PA66 melts at a higher temperature and handles heat better. It is also stiffer and stronger than PA6. PA6 takes in more water and can handle hits better. This makes PA6 good for parts that might get bumped or dropped.

The table below shows how PA6 and PA66 are different:

| Property | PA6 | PA66 |

|---|---|---|

| Density (g/cm³) | 1.13 | 1.15 |

| Melting Point (°C) | 215-220 | 255-265 |

| Tensile Strength (MPa) | 70-80 | 80-90 |

| Flexural Strength (MPa) | 90-100 | 100-120 |

| Impact Strength (kg/m²) | 60 | 22 |

| Heat Deflection Temp (°C) | 68 | 75 |

| Elongation (%) | 15-25 | 20-30 |

| Water Absorption (%) | 1.2-1.5 | 0.7-0.9 |

| Shrinkage (%) | 1.0-1.5 | 0.5-1.2 |

PA66 is great for car and electric parts that get hot or need to be strong. PA6 costs less and lasts longer when heated over time. Both are part of the Nylon Materials group, but engineers pick one based on what the part needs to do.

Tip: Use PA66 if you need more heat and strength. Pick PA6 if you want better impact strength and a lower price.

PA12 Features

PA12 is known for being bendy and tough. Many companies use PA12 for hoses and tubes because it bends without breaking. Some main features are:

- Very flexible and strong, so it bends easily.

- Tough and can take hits without breaking.

- Stands up well to oil, acids, solvents, rubbing, and sunlight.

- Does not catch fire easily and puts out flames by itself.

- Works in cold and hot places, from -50°C to 100°C, and short times up to 150°C.

- Takes in little water, so it keeps its shape even when wet.

- Light and simple to put in, with good sealing and stops shaking.

PA12 tubes are used in big machines, electric cars, and places that need to keep out water and dust. Its mix of softness, toughness, and chemical resistance makes it a top pick for flexible tubes.

PPA Advantages

PPA, or polyphthalamide, has some big pluses over other nylons. It works well in hot places and stays strong even after a long time in heat. The table below shows how PPA is different from other nylons:

| Property | PPA | Nylon 6 (PA6) | Nylon 6/6 (PA66) |

|---|---|---|---|

| Heat Resistance | >280°C | Moderate | High |

| Mechanical Strength | High stiffness, excellent creep resistance | Good strength | High strength |

| Chemical Resistance | Excellent | Good | Excellent |

| Moisture Absorption | Very low (0.1-0.3%) | Higher | Higher |

| Dimensional Stability | Excellent | Moderate | High |

PPA does not break down or rust in heat, especially with special stabilizers. This makes it perfect for car engines, electric connectors, and machine parts that get hot. PPA also takes in much less water than other nylons, so it keeps its size and shape better.

Note: PPA is the best pick for tough jobs where regular nylon might not work because of heat or chemicals.

Reinforced Nylons

Engineers pick reinforced nylons when they want parts that are stronger and tougher. Reinforced nylons are made by mixing nylon polymers with glass fibers or carbon fibers. These fibers change how the nylon acts and make it better for hard jobs.

Glass fiber reinforced nylon is used a lot. Adding glass fibers makes nylon much stiffer and stronger. This kind of nylon is good for car engine covers, gears, and electrical housings. Glass fibers help nylon keep its shape when pressed or heated. They also help nylon take hits without breaking.

But if there are too many glass fibers, the nylon can get brittle and hard to shape. Carbon fiber reinforced nylon is even stronger. Carbon fibers give nylon more strength and stiffness than glass fibers. Studies show carbon fiber reinforced nylon can be up to 6.3 times stronger than regular nylon. It can also be up to five times stiffer.

Carbon fiber makes nylon lighter, which is good for cars and airplanes. But carbon fiber can make nylon more brittle, so it may not take hits as well as glass fiber reinforced nylon. The way fibers are placed in nylon matters too. If fibers go the same way as the force, nylon gets much stronger and stiffer. This is called fiber orientation. A 0° fiber orientation gives the most strength and stiffness. If fibers are not lined up, nylon is not as strong.

| Feature | Glass Fiber Reinforced Nylon | Carbon Fiber Reinforced Nylon |

|---|---|---|

| Tensile Strength | High | Very High |

| Flexural Strength | High | Very High |

| Stiffness | High | Very High |

| Impact Resistance | Very Good | Moderate |

| Weight | Moderate | Low (lighter) |

| Brittleness | Moderate | Higher |

Reinforced nylons help Nylon Materials work in places where regular nylon is not strong enough. Car makers use them for parts under the hood. Electronics companies use them for connectors and housings. Even 3D printing uses reinforced nylons to make strong and light parts. The best choice depends on if the part needs to be strong, stiff, light, or able to take a hit.

Tip: When choosing reinforced nylons, think about what the part must do. Glass fiber helps with impact resistance. Carbon fiber gives more strength and stiffness.

Applications

Automotive

Nylon is very important in making cars. In 2024, car companies make up 35.6% of the nylon fiber market. This means nylon is used a lot for car parts. Car makers like nylon because it is light and strong. It also stands up to heat and chemicals. These things help cars be safer and cheaper to build.

Engine Parts

Engine parts get hot and move a lot. Nylon works well in these hard places. Factories use nylon for engine covers, intake manifolds, gears, and bearings. They pick nylon instead of metal for many reasons:

- Nylon lasts a long time and does not wear out fast.

- It is strong but does not weigh much.

- Nylon does not rust or corrode like metal.

- It has low friction, so moving parts last longer.

- Nylon can take heat found in engines.

Nylon washers work well in hot engine areas. They do not get damaged by oils and fluids. Nylon also absorbs shock and noise better than metal. This makes cars quieter. Nylon is easy to shape into many forms. High-temperature nylon with glass fiber is 20% stronger than regular nylon. It can take heat up to 280°C, which is more than normal nylon. This makes it great for engine parts that need to be exact.

Tip: Nylon Materials help make cars lighter. This helps cars use less fuel and pollute less.

Battery Housings

Electric and hybrid cars need safe battery housings. Nylon is a top pick for these parts. It keeps batteries safe from heat, chemicals, and bumps. Nylon is light, so cars are not too heavy. Its chemical resistance keeps batteries safe from leaks. Nylon battery housings can be made into tight shapes. This keeps batteries safe and saves space.

Aerospace

The aerospace industry needs materials that are light and strong. Nylon is good for this. Engineers use nylon in many airplane parts to make planes lighter and save fuel.

Structural Parts

Nylon is used for fasteners, brackets, engine mounts, and panels. Sometimes, nylon is mixed with carbon fiber or glass fiber. This makes the parts even stronger and stiffer. The table below shows how nylon helps in airplanes:

| Aspect | Description |

|---|---|

| Applications | Fasteners, brackets, engine mounts, fuselage panels, wing skins, control surfaces |

| Composite Materials | Mixed with carbon or glass fiber for more strength |

| Performance Benefits | High strength-to-weight ratio, resists fatigue, handles chemicals, stands up to high heat |

| Manufacturing Innovations | Allows 3D printing for quick, accurate parts |

| Overall Impact | Lighter, more fuel-efficient planes; better safety and comfort |

Nylon is used in 3D printing to make custom airplane parts fast. This saves time and money. Lighter planes use less fuel and can carry more people or cargo.

Cable Insulation

Planes have lots of wires and cables. Nylon covers these cables to keep them safe from heat and chemicals. It also stops cables from wearing out. Nylon keeps electric signals safe and stops shorts. It is flexible, so cables can fit in small spaces. Nylon also stands up to shaking and movement during flights.

Consumer Goods

Nylon is found in many things we use every day. It is strong, bends easily, and does not wear out fast. This makes it a favorite for designers and buyers.

Toys

Toy makers use nylon for gears, wheels, and moving parts. Nylon is tough, so toys last longer even if played with roughly. It does not break or lose shape easily. Nylon is safe for kids because it does not splinter or crack.

Sports Equipment

Nylon is used in tennis racket strings, fishing lines, and safety gear. Its strength and flexibility help sports gear work better. Nylon does not wear out fast, even with lots of use. It can handle sweat and water without getting weak.

Home Appliances

Many home appliances have nylon parts like gears, handles, and covers. Nylon is strong and does not get damaged by chemicals. It can take heat and does not bend out of shape. The table below lists common things made from nylon and why it is good for them:

| Common Consumer Goods Made from Nylon | Relevant Properties Making Nylon Suitable |

|---|---|

| Toothbrushes, combs, utensils | Strong, does not get damaged by chemicals |

| Luggage, backpacks, footwear | Tough, flexible, looks nice |

| Sporting equipment, power tools | Strong, does not wear out fast |

| Zippers, buckles, handles | Strong, does not wear out fast |

| Personal care products | Strong, does not wear out fast |

| 3D printed parts | Handles hits, bends easily, resists chemicals |

Nylon’s structure makes it strong and flexible. It stands up to oils, greases, and solvents. Nylon does not wear out fast and can stretch or bend. Nylon Materials help make products that last longer and work better every day.

Electronics

Connectors

Nylon is important in electrical connectors. Factories use nylon because it is tough and insulates electricity. Nylon connectors are hard to break. They can handle plugging and unplugging many times. These connectors work in hot places up to 105°C. Nylon also stands up to many oils and chemicals. This helps connectors last longer and keeps devices safe.

Factories shape nylon connectors with injection molding. This makes strong and exact parts. Nylon connectors stay strong after lots of use. Nylon keeps wires apart, so it helps stop electrical shorts.

Cables

Nylon is used as a cover over cable insulation. This cover makes cables stronger and helps them last longer. Nylon protects wires from cuts and scrapes during setup. It also keeps out damage from oils, greases, and chemicals. This keeps cables safe in tough places.

Nylon coatings help cables slide through tight spots. This makes putting in cables faster and easier. The nylon cover blocks some water, which helps stop shorts. Nylon does not block all water, but it still helps protect.

Some reasons for using nylon in cables are:

- Nylon covers protect wires from damage.

- They fight chemicals, so cables last longer.

- The nylon layer helps keep out water.

- Cables with nylon can take sunlight and hits better.

- Nylon makes it easier to pull cables through pipes.

- The cover adds a safety layer against electrical trouble.

- Nylon helps cables last longer, which saves money.

| Property | Description |

|---|---|

| Material | Nylon (Polyamide, PA) |

| Appearance | Milky white |

| Mechanical Toughness | Good toughness |

| Abrasion Resistance | Good abrasion resistance |

| Odor | Odorless |

| Processing Methods | Drilling, cutting, planing, injection molding |

| Creep Resistance | Good (KB600) |

| Moisture Absorption | Present |

| Heat Resistance | Up to 105°C |

Tip: Nylon coatings help cables and connectors last longer and work better in many places.

Industrial

Gears

Nylon gears are used in many machines. They often take the place of metal gears. Nylon gears are lighter and make less noise. They do not wear out fast and need little oil. This helps machines run well and need fewer repairs. Factories use nylon gears in belts, printers, and packing machines.

Bearings

Nylon bearings help machines move with less rubbing. These bearings are strong and can hold heavy things. They do not rust and work in wet or dirty places. Nylon bearings last a long time and help save on repairs. Many factories use nylon bearings in pumps, fans, and other moving parts.

Packaging Machinery

Nylon is used in many parts of packing machines. It is used for rollers, guides, and bushings. Nylon can handle fast moves and pressure in these machines. It also stands up to cleaning chemicals and packing stuff. Using nylon helps factories work faster and have fewer problems.

| Property / Feature | Industrial Application Areas | How It Improves Operational Efficiency |

|---|---|---|

| High Strength & Durability | Automotive parts, industrial machine components | Makes parts last longer and need less fixing |

| Lightweight & Flexible | Automotive and aerospace components | Helps make lighter parts, saving fuel and working better |

| Heat Resistance | Automotive, electrical components | Keeps working in heat, so parts last longer |

| Chemical Resistance | Automotive, industrial environments | Fights damage from oils and solvents, so parts last longer |

| Low Friction & Self-Lubricating | Bushings, bearings, gears in vehicles | Less rubbing and wear, so machines work better and need less care |

| Versatility in Manufacturing | Injection molding, extrusion, 3D printing | Makes it easy to create many shapes, saving time and money |

Note: Nylon Materials help factories save money by making machines that last longer and need less care.

Textiles

Yarns

Nylon yarns are strong and stretch well. Factories spin nylon into thin threads for many things. These yarns make light, smooth, and tough fabrics. People use nylon yarns in stockings, ropes, and sports clothes. The yarns do not break easily and can take pulling and twisting.

Apparel

Nylon is liked for clothing because it feels soft and dries fast. Nylon clothes are light and comfy. They keep their shape after washing and do not wrinkle much. Nylon is used in jackets, swimwear, and sports gear. The fabric fights stains and does not fade in sunlight. Designers mix nylon with other fibers to make clothes even stronger.

Nylon Materials have changed the textile world. They help make clothes and fabrics that last longer and look better.

Best Practices

Preparation

Drying

Nylon takes in water from the air very fast. This water can make problems when making parts, like bubbles or weak spots. To stop this, factories dry nylon pellets before using them. Most nylon types need drying at 80–100°C for 4–8 hours. The goal is to get the water level below 0.2%. Some companies use vacuum drying at 80–120°C for up to 48 hours if the pellets are very wet. After drying, pellets should cool below 70°C in a vacuum so they do not change color.

Tip: Always check how much water is in nylon before using it. Dry nylon well to stop surface problems and make strong, good parts.

Storage

Good storage keeps nylon pellets dry and ready to use. Factories keep pellets in sealed bags that block water. After opening, they use all the pellets fast or close the bag tight again. Nylon should not sit out in the hopper for a long time. In wet air, only leave it out for 30–60 minutes. In dry air, 3–4 hours is okay. Storage rooms with climate control help stop water from getting in. Workers handle bags with care and do not put them in wet places.

Best storage practices:

- Use sealed bags or metal cans.

- Keep storage cool and dry.

- Do not let pellets touch air for long.

- Only keep what you need near machines.

Processing

Injection Molding

Injection molding is a common way to shape nylon. Pellets must be dry before molding. Factories set the heat by the nylon type: 230–280°C for PA6, 250–300°C for glass-filled PA66. If the heat is over 300°C, nylon can get ruined. Injection pressure is between 55–138 MPa to fill the mold. Workers control speed to stop flow lines and damage. Cooling time depends on how thick the part is and the mold shape. Good mold design, like where the gate and vents are, helps make strong, smooth parts.

Extrusion

Extrusion shapes nylon into rods, tubes, and threads. The heat settings are like injection molding. After shaping, nylon cools in water or on cold rollers. This step helps nylon keep its shape and strength.

3D Printing

3D printing with nylon needs dry filament. Wet filament can make bad prints. People keep nylon spools in closed boxes with drying packs. Printers use nozzle heat between 240–260°C for most nylon. Heated beds and covers help stop warping and help layers stick together.

Post-Processing

After shaping, nylon parts may need more work. Workers cut, drill, or polish parts to get the right size and look. Sometimes, they heat parts gently to lower stress and make them more stable. Good post-processing makes nylon parts look nice and work well in their final job.

Note: Careful prep, processing, and finishing help nylon parts work their best in any use.

Challenges

Warping

Warping is a big problem with nylon materials. It happens a lot in 3D printing and molding. Warping starts when parts cool at different speeds. The outside cools faster than the inside. This makes the material shrink in some places more than others. Because of this, the part can bend or lift up from the print bed. Warping can mess up the shape and use of nylon parts.

Some things make warping worse:

- If the part cools unevenly, it gets stressed inside.

- Nylon shrinks more than many other plastics as it cools.

- Wet nylon filament can make bubbles and weak spots, which cause more warping.

People use different ways to stop warping:

- Heated beds and chambers keep the temperature steady.

- Good bed adhesion helps the part stay flat while printing.

- Controlling airflow and room heat stops quick cooling.

- Drying nylon filament before use takes out extra water.

- Storing filament in airtight bags with drying packs keeps it dry.

- Changing print settings, like slowing the first layer and using brims or rafts, helps parts stick better.

Tip: Always watch the temperature and humidity in your workspace. Even small changes can make warping better or worse.

Moisture Issues

Nylon soaks up water from the air very fast. This is called hygroscopicity. When nylon filament or pellets get wet, problems happen during printing or molding. Wet nylon can make bubbles, weak layers, and soft spots in finished parts. Water also makes nylon harder to print or mold because it changes how it moves.

You can spot moisture problems if you see:

- Popping or hissing sounds when printing.

- Rough or bumpy surfaces on printed parts.

- Weaker parts and poor sticking between layers.

To stop moisture problems, people:

- Dry nylon filament or pellets before use, usually at 80–100°C for a few hours.

- Store nylon in closed containers with drying packs.

- Use filament dryers or dry boxes while printing.

Note: Even a little water can cause big problems in nylon parts. Always keep nylon as dry as you can for the best results.

Surface Finish

Surface finish means how smooth or rough a nylon part feels and looks. Many people want a smooth, shiny finish for looks and for parts to work well. But nylon can be hard to finish nicely. Problems like warping and moisture can make the surface rough or bumpy. Bad print settings or dirty molds also make the part look worse.

You can get a better surface finish by:

- Using dry, good-quality nylon.

- Setting the right print or mold temperature.

- Slowing down the print speed for better layers.

- Polishing or sanding the finished part.

- Adding coatings or paint for a smoother look.

A good surface finish helps nylon parts fit together better and last longer. It also makes products look nicer and more professional.

Mechanical Failures

Mechanical failures happen when nylon parts break, crack, or lose their strength during use. These failures can cause machines to stop working or products to break. Understanding why nylon fails helps engineers make better and safer products.

Common Types of Mechanical Failures in Nylon:

- Cracking: Nylon can crack if it faces too much force or if it gets hit suddenly. Small cracks can grow over time, leading to bigger breaks.

- Fatigue: When nylon bends or moves back and forth many times, it can get weak. This is called fatigue. Parts like gears or hinges often face this problem.

- Creep: If nylon holds a heavy load for a long time, it can slowly change shape. This slow change is called creep. Creep can make parts fit poorly or stop working.

- Brittleness: Nylon can become brittle if it dries out too much or gets too cold. Brittle nylon breaks more easily.

- Stress Concentration: Sharp corners or notches in a part can focus stress in one spot. These spots are more likely to crack or break.

Tip: Engineers can lower the risk of failure by using smooth shapes and avoiding sharp corners in their designs.

Main Causes of Mechanical Failures:

| Cause | Description | Example |

|---|---|---|

| Overloading | Too much weight or force on the part | Gear teeth breaking |

| Poor Design | Sharp corners, thin walls, or bad shapes | Cracks at notches |

| Environmental Stress | Heat, cold, or chemicals weaken the nylon | Brittle parts in cold weather |

| Moisture Changes | Wet or dry nylon changes size and strength | Warped or cracked housings |

| Aging | Nylon gets weaker over time | Old parts snapping |

How to Prevent Mechanical Failures:

- Choose the right type of nylon for the job. Some nylons handle heat, cold, or chemicals better than others.

- Add glass or carbon fibers to make nylon stronger and stiffer.

- Design parts with smooth curves and even thickness. Avoid sharp corners.

- Dry nylon before making parts. Wet nylon can lead to weak spots.

- Test parts under real-life conditions to find weak points early.

Note: Regular checks and good design help nylon parts last longer and work better.

Mechanical failures can cost time and money. By understanding these problems, engineers can make nylon products that are safer and more reliable.

Future Trends

Sustainability

Sustainability is now very important for Nylon Materials. Companies want to make nylon in cleaner and better ways. Toray Industries made a new recycling process for nylon 66. This process uses special water to break nylon into its basic parts in just minutes. It can lower carbon emissions by up to half compared to old ways. Toray wants to use this process in big factories by 2030. The plan is to reuse old nylon to make new things, like airbags and tire cords for cars.

Other companies also try to make nylon better for the planet. Some use plants to make biobased nylons, like Pebax® Rnew®. These nylons come from plants and can be recycled. Factories now collect waste from making and using nylon to recycle it. There are rules, like the Global Textile Recycling Standard, to help track and support these actions. ECONYL® is a famous recycled nylon made from old fishing nets and sea trash. BASF has a process called ChemCycling™ that turns mixed plastic waste into new nylon 6. Many companies now design products with only one material to make recycling easier. They also want to use more recycled and plant-based nylon in their products.

But recycling nylon still has some problems. There are not enough ways to collect old nylon from people. This makes it hard to get enough nylon to recycle. Experts think plant-based nylons could soon take the place of fossil-based ones. They can use the same machines and recycling steps.

♻️ The future of nylon depends on better recycling, cleaner ways to make it, and smart design choices.

Advanced Composites

Advanced composites are changing how people use Nylon Materials. These materials mix nylon with glass or carbon fibers. This makes them much stronger and lighter than regular nylon. Car makers use these composites to build lighter cars that use less fuel. Airplane makers also pick advanced composites to make planes safer and better.

Factories can shape advanced composites into many forms. This lets engineers make parts that fit well and last longer. Some composites can even take high heat and strong chemicals. These features make them good for engines and tough machines.

Advanced composites help industries meet new needs for strength, weight, and lasting power.

Smart Nylons

Smart nylons are a new step in material science. These nylons can change how they act based on their surroundings. For example, some smart nylons can sense heat or wetness. Others can fix small cracks by themselves. Scientists add special chemicals or change the nylon’s structure to give these powers.

Smart nylons can help make safer cars, better medical tools, and stronger electronics. They can also cut down on waste because they last longer and need fewer repairs. As scientists keep working, smart nylons may be used in many products.

Smart nylons show how new ideas can make materials more helpful and flexible for the future.

Recycling

Recycling is now very important for companies that use nylon. Many people throw away nylon products after using them. This makes a lot of trash. Factories and scientists want to recycle nylon and use it again. They hope to save resources and help the planet.

There are two main ways to recycle nylon. The first way is called mechanical recycling. Workers collect old nylon, clean it, and melt it. Then they shape the melted nylon into new things. This works best if the nylon is clean and sorted. The second way is chemical recycling. Factories break nylon into its basic parts using heat, water, or chemicals. After that, they build the nylon back into new material. Chemical recycling can work with dirty or mixed nylon waste.

Some companies use recycled nylon to make new things. For example, they turn old fishing nets into carpet or clothes. ECONYL is a famous brand that makes nylon yarn from waste found in oceans and landfills. This helps stop pollution and saves energy.

Recycling nylon has many good points:

- It means we need less new material.

- It cuts down on trash in landfills.

- It uses less energy than making new nylon from oil.

- It helps lower greenhouse gas emissions.

But recycling nylon also has some problems. Sorting and cleaning nylon waste is not easy. Some products mix nylon with other materials, which makes recycling harder. Not all places have the right tools to collect and process nylon waste.

Here is a table that shows the main steps in nylon recycling:

| Step | Description |

|---|---|

| Collection | Gather used nylon products |

| Sorting | Separate nylon from other materials |

| Cleaning | Remove dirt and unwanted substances |

| Processing | Melt or break down nylon |

| Remanufacturing | Shape recycled nylon into new products |

♻️ Recycling gives nylon another chance to be used and keeps trash out of nature.

Many experts think better recycling will help Nylon Materials be more eco-friendly. New technology and better ways to collect nylon will make recycling easier soon.

Nylon materials are still very important in many industries. They are strong, bend easily, and last a long time. If people know about nylon’s properties, they can pick the right type for each job. New ideas and eco-friendly ways will change how nylon is used in the future.

Key Takeaways:

- Nylon works for many things, like cars and clothes.

- New inventions and recycling keep nylon useful.

Engineers and designers should keep learning about nylon. This helps them make better products that are good for the planet.

FAQ

Nylon stands out because it is strong, flexible, and resists wear. Many plastics break or crack under stress. Nylon can bend and return to shape. Factories use nylon for parts that need to last a long time.

Yes, companies can recycle nylon. They collect, clean, and melt old nylon to make new products. Some brands use recycled nylon from fishing nets or carpets. Recycling nylon helps reduce waste and saves resources.

Nylon absorbs water from the air. This can change its size and strength. Some types, like PA12, take in less water. Engineers often dry nylon before making parts to keep them strong and stable.

Many types of nylon are safe for food contact. Factories use food-grade nylon for kitchen tools and packaging. Always check if the product says “food safe” before using it with food.

Glass or carbon fibers make nylon much stronger and stiffer. These fibers help nylon parts hold heavy loads and keep their shape. Engineers use reinforced nylon in cars, airplanes, and machines.

People find nylon in clothes, toothbrushes, zippers, and sports gear. Factories use nylon for car parts, gears, and electrical connectors. Nylon’s strength and flexibility make it useful in many products.

Keep nylon in sealed bags or containers. Store it in a cool, dry place. This stops nylon from absorbing water, which can cause problems during processing or printing.

Yes, nylon works well in 3D printing. It makes strong, flexible parts. Users must keep nylon filament dry for the best results. Nylon prints are popular for tools, gears, and custom parts.