You need more precise machining parts teflon material because industries like cars and electronics are growing fast. PTFE is special because it does not react with chemicals and can handle heat well. This makes it a great choice for these industries. Quality control is very important at every step. Workers check the material first and then check the finished parts with special tools like CMMs. If you work with trusted companies like AFI Industrial Co., Ltd., you get skilled workers and modern CNC machines. These help you make parts that fit exactly right and work well every time.

Table of Contents

Key Takeaways

- PTFE (Teflon) is very slippery and can handle heat. It does not react with most chemicals. This makes it great for parts that need to last and stay strong.

- Use sharp carbide or diamond tools when cutting PTFE. Set the right speed and feed rate. This helps you cut PTFE well and keeps it from getting hurt.

- Keep PTFE parts cool while you work on them. Use air or mist cooling. Do not use oil-based lubricants. Oil can hurt the surface.

- Hold PTFE parts gently with soft jaws or a vacuum. This stops bending or marks. It also keeps the size of the part correct.

- Pick virgin PTFE if you need it pure or safe for food. Use filled PTFE with glass or carbon if you want it stronger. This also helps it last longer.

- Plan your work to make less waste. Design simple parts. Use CNC machines. Set normal tolerances if you can.

- To get a smooth finish, use sharp tools and low feed rates. Polish or buff the part after cutting. This makes the part smooth and strong.

- PTFE parts are used in many places. You can find them in planes, hospitals, cars, food factories, and machines. They are chosen because they last long and work well.

Teflon (PTFE) Properties

Physical Traits

When you pick Teflon (PTFE) for machining, you get special physical traits. PTFE is very slippery. Water does not stick to it. Scientists use something called water contact angle to measure this. Clean PTFE has a contact angle of about 142°. This means water forms beads and rolls off fast. Because of this, PTFE is great for things that need to be non-stick and easy to clean.

PTFE can handle very hot and very cold places. It works in cold as low as -198°C and heat up to 200°C. Its shape stays the same even if you squeeze it hard or stretch it a lot. PTFE does not break easily when pressed. You can see these facts in the table below:

| Property/Parameter | Values/Range | Description/Notes |

|---|---|---|

| Water Contact Angle | ~142° | High hydrophobicity |

| Temperature Range | -198°C to 200°C | Maintains properties across wide temperature range |

| True Strain Values | Up to 50% | Withstands large deformation without failure |

| Poisson Ratio | Measured via gauges | Shows flexibility and shape retention |

Tip: If you want a part that does not stick, can take heat, and keeps its shape, PTFE is a good pick.

Chemical Resistance

You want your parts to last in tough places. PTFE gives great chemical resistance. It does not react with most acids, bases, or solvents. This makes it good for chemical plants, food work, and medical tools. PTFE does not soak up water, so it will not swell or break down in wet places.

Here is a quick look at PTFE’s chemical resistance:

| Property | Rating/Range |

|---|---|

| Chemical Resistance | Excellent |

| Temperature Resistance | -200°C to +260°C |

| Water Absorption | None |

PTFE has strong carbon-fluorine bonds. These bonds help it resist chemicals. Even in fire, PTFE stays stable until it gets very hot. When it does break down, it makes gases like hydrogen fluoride, but only at very high heat. This means you can trust PTFE in hard jobs.

Comparison with Plastics

If you compare PTFE to other plastics, you see big differences. PTFE can take more heat and more chemicals than plastics like HDPE. But PTFE is not as strong when you pull or hit it. It also costs more and is harder to recycle.

| Property | Teflon (PTFE) | HDPE |

|---|---|---|

| Chemical Resistance | Superior | Good |

| Temperature Range | -200°C to +260°C | -50°C to +80°C |

| Tensile Strength | Lower | Higher |

| Impact Resistance | Lower | Better |

| Friction Coefficient | Very low (non-stick) | Higher |

| Cost | Higher | More cost-effective |

| Recycling | Difficult | Widely recycled |

If you need a part for high heat or strong chemicals, pick PTFE. If you want something cheaper and stronger, HDPE or other plastics might be better. Always choose the right material for your job.

Machining Parts Teflon Material

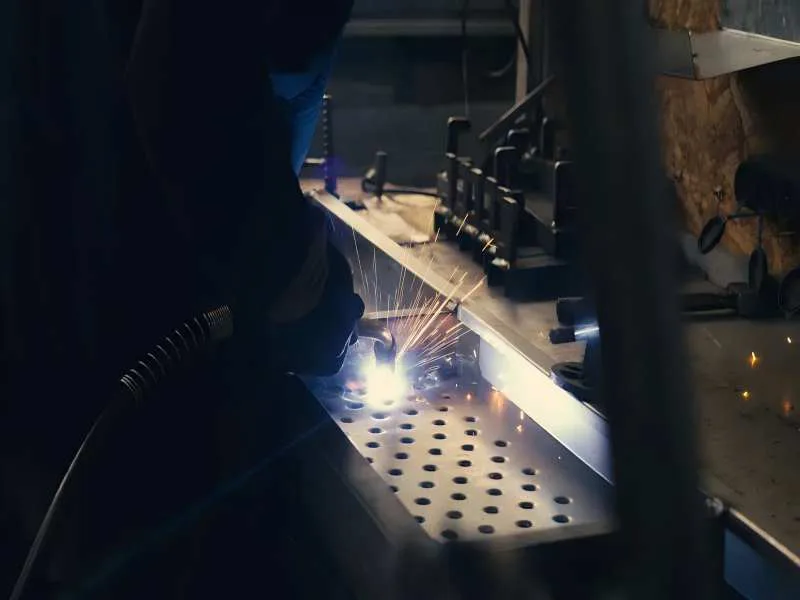

CNC Milling

CNC milling helps you make very exact parts from teflon material. PTFE is soft and slippery, so it is easy to cut. You need to pick the right tools and settings. Use sharp carbide or stellite-tipped tools. These tools stay sharp longer and make smooth cuts. Pick a positive rake angle between 0 and 15 degrees. This makes cutting easier and keeps the shape right.

AFI Industrial Co., Ltd. uses 5-axis CNC milling machines. These machines can make hard shapes with fewer steps. This saves time and makes parts more accurate. Keep the cutting speed between 200 and 500 surface feet per minute. Use a slow feed rate, about 0.002 to 0.010 inches per turn. This keeps the part cool and steady.

Tip: Always check your tools and keep them sharp. Dull tools can make rough parts and bad sizes.

Use air or mist cooling to stop the part from getting too hot. Do not use oil-based lubricants because they can change the surface. Clamp the PTFE gently. Too much pressure can bend the part.

| Parameter | Best Practice / Benchmark |

|---|---|

| Cutting Speed | 200–500 surface feet per minute |

| Feed Rate | 0.002–0.010 inches per revolution |

| Tooling | Carbide or stellite-tipped, positive rake (0–15°) |

| Cooling | Air or mist cooling |

| Clamping Pressure | Minimal, avoid deformation |

| Machining Method | 5-axis CNC milling for complex shapes |

Turning

Turning is another way to shape PTFE parts. You use a lathe to spin the teflon material and cut it. Use sharp carbide or high-speed steel tools. Keep the cutting speed low, between 200 and 500 surface feet per minute. Use a slow feed rate to stop heat and warping.

Clamp the PTFE lightly. If you clamp too hard, it can bend. Always check if your tool is sharp. Sharp tools make smoother parts and better sizes. AFI Industrial’s workers use these tips to make parts with tight sizes and smooth surfaces.

- Use sharp tools for smooth cuts.

- Keep speeds and feeds low.

- Clamp gently.

- Check parts often for size.

Note: PTFE can change shape after you machine it. Let the part rest before you measure it to make sure the size is right.

Drilling

Drilling PTFE needs extra care. The material is soft and makes long chips. Use sharp drills and slow feed rates. This stops the hole from tearing or changing shape. For small holes up to 0.197 inches, set the speed to 1000 rpm. For bigger holes up to 0.591 inches, use 600 rpm. Keep the feed rate between 0.005 and 0.009 inches per turn.

To make holes more exact, drill twice. First, make a rough hole. Then, finish it with a second pass. Move the drill in and out to clear chips and keep it cool. After drilling, let the part sit for 24 hours before measuring. This helps the part keep its shape.

| Drilling Parameter | Recommendation | Impact |

|---|---|---|

| Spindle Speed (small hole) | 1000 rpm | Fast, accurate drilling |

| Spindle Speed (large hole) | 600 rpm | Reduces deformation |

| Feed Rate | 0.005–0.009 in/rev | Prevents tearing |

| Drilling Technique | Two-pass (coarse + finish) | Improves precision |

| Tool Movement | In-out motion | Manages heat and chip removal |

| Material Relaxation | 24 hours before final measurement | Ensures dimensional accuracy |

Tip: Always clear chips when drilling. Long chips can block the drill and hurt the hole.

If you follow these steps, you can make great PTFE parts. The parts will have tight sizes and smooth surfaces. AFI Industrial’s machines and skilled team help you get the best results when machining parts teflon material.

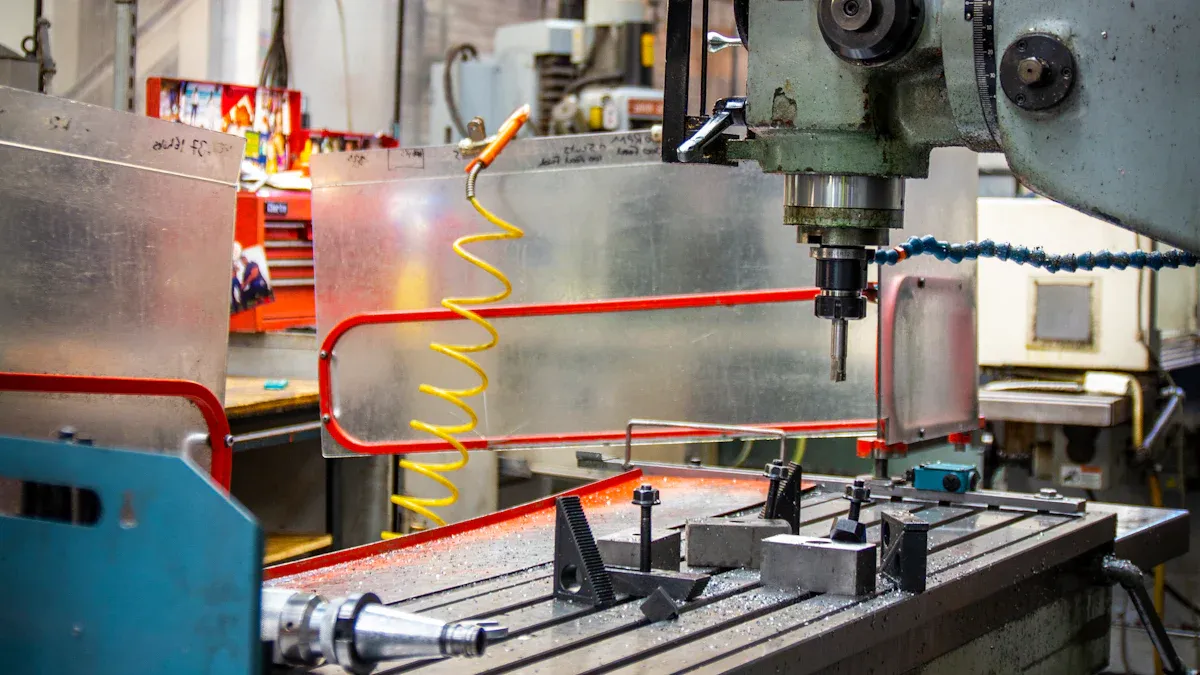

Tooling & Parameters

When you machine PTFE, you need the right tools and settings to get the best results. PTFE is soft and can deform if you use the wrong parameters. You should always use sharp, uncoated carbide or diamond tools. These tools cut cleanly and do not hold heat. Dull tools can tear the material and leave rough edges.

Here are the best practices for tooling and parameters:

- Cutting speeds between 150 and 300 meters per minute help you avoid ragged edges.

- Feed rates from 0.1 to 0.3 millimeters per revolution give you a smooth finish and stable machining.

- Use soft jaw clamps or custom fixtures to hold the part. This prevents the PTFE from bending or changing shape.

- Check your tool wear often. Worn tools can change the size and surface of your part.

- Try climb milling and pull the tool out sometimes to clear chips. This keeps the cut clean and stops chips from blocking the tool.

- Aim for a surface roughness below Ra 0.8 micrometers. You can reach this with the right settings and sharp tools.

- After machining, let the part rest or anneal it. PTFE can expand or shrink with temperature, so this step helps keep the size correct.

Tip: Always monitor the temperature during machining. PTFE melts at about 327°C. If it gets too hot, it can deform or lose its shape.

Research shows that the right combination of cutting speed, feed rate, and tool geometry can improve both surface finish and productivity. You can use computer models and experiments to find the best settings for your job. When you work with a partner like AFI Industrial, you get access to advanced CNC machines and skilled operators who know how to set these parameters for machining parts teflon material.

Cooling Methods

PTFE does not handle heat well during machining. You need to keep the part cool to avoid melting or warping. The best way to cool PTFE is with air or a fine mist. Do not use oil-based coolants because they can change the surface of the part.

Follow these steps for cooling:

- Use compressed air to blow away chips and cool the cutting area.

- For high-speed jobs, add a mist coolant system. This gives extra cooling without soaking the part.

- Keep the coolant flow steady. Sudden changes in temperature can cause the PTFE to crack or deform.

- Avoid flooding the part with liquid. PTFE does not absorb water, but too much liquid can make the part slippery and hard to hold.

- After machining, let the part cool down slowly at room temperature. Quick cooling can cause stress and change the size of the part.

Note: Good cooling helps you get a better surface finish and keeps your part the right size. Always check the temperature during machining parts teflon material.

When you use the right cooling methods and tooling parameters, you can make high-quality PTFE parts that meet tight tolerances. AFI Industrial’s advanced CNC machines and strict quality checks help you get the best results every time.

Machining Challenges

Heat Management

When you machine parts teflon material, heat is a big problem. PTFE gets bigger or smaller fast when it gets hot or cold. If it gets too hot, it can bend or lose its shape. You must keep the heat low all the time.

Use sharp carbide tools for cutting. Keep your cutting speed between 200 and 500 feet per minute. Set your feed rate from 0.002 to 0.010 inches per turn. These settings help stop too much rubbing and heat. Always use air or a fine mist to cool the part. Do not use oil coolants because they can change the PTFE surface.

Look at this table to see how PTFE acts with heat:

| Property | Behavior with Higher Temperature | What You Should Do |

|---|---|---|

| Tensile Strength | Drops up to 75% at 260°C | Use low loads and avoid overheating |

| Compressive Strength | Decreases sharply | Clamp gently and check for deformation |

| Creep Resistance | Gets much worse | Avoid long machining times in one spot |

| Thermal Expansion | Increases a lot | Machine in a cool, stable environment |

| Thermal Conductivity | Gets lower | Use air or mist to remove heat |

Tip: Let your PTFE parts cool down slowly after you finish. If you cool them too fast, they can get stressed and change shape.

Dimensional Stability

It is hard to keep PTFE parts the right size and shape. This material grows and shrinks more than metals do. You need to plan for this when you machine parts teflon material.

Here are some ways to keep your parts stable: Work in a room with steady temperature. Use soft clamps or vacuum to hold the part. Take off the same amount of material from each side. Let the part rest or heat it before you measure the final size.

Normal size limits for PTFE are ±0.13mm. If you need tighter limits, like ±0.05mm, you must use special holders and watch the temperature closely. PTFE can move up to ten times more than metals when it gets hot or cold. Always check your parts with a CMM or other good measuring tool after they cool down.

Note: Try making your parts a little bigger at first. You can cut them down to the right size after they settle.

Surface Finish

Getting a smooth surface on PTFE is tough. The material is soft and slippery, so it can tear or look rough. You need sharp tools and good settings to get a nice finish.

Most CNC machines give a surface roughness of about 3.2 micrometers. If you want it smoother, like for seals, you can polish it to 0.8 micrometers. Studies show that smoother PTFE works better for sealing and lasts longer.

To get a better surface: Use sharp, uncoated carbide tools. Set low feed rates and high cutting speeds. Polish the part after you cut it if you need to. Check the surface with a tester.

Tip: Always decide what surface finish you want before you start. This helps you pick the right tools and steps for your work.

Fixturing Tips

When you machine PTFE, you must pay close attention to how you hold the part. PTFE is soft and flexible. If you clamp it too hard, you can leave marks or even change its shape. You want to keep your part steady, but you do not want to crush it.

Start by choosing the right fixture. Soft jaws made from aluminum or plastic work well. These jaws spread the clamping force over a larger area. This helps you avoid dents and keeps the part’s shape. For thin or delicate parts, vacuum fixtures offer gentle but firm holding. You can also use contour-matched supports. These supports match the shape of your part and help prevent bending or spring-back.

Tip: Always check that your fixture holds the part evenly. Uneven pressure can cause the PTFE to deform during machining.

You should also control the temperature in your work area. PTFE expands and contracts with heat. If the room gets too hot or cold, your part can change size. Try to keep the temperature close to room temperature. This helps you keep tight tolerances and makes your measurements more reliable.

Here are some practical steps for fixturing PTFE:

- Use soft jaws or custom clamps to avoid surface marks.

- Choose vacuum fixtures for thin-walled or flexible parts.

- Match the fixture shape to your part for better support.

- Spread clamping force over the largest area possible.

- Avoid over-tightening. Light, even pressure works best.

- Keep the work area at a steady temperature.

Research shows that using these fixturing methods can reduce deformation by about 30%. You can also improve the dimensional accuracy of your PTFE parts by up to 40% when you combine good fixturing with the right cutting tools and temperature control. These steps are especially important when you need high precision for machining parts teflon material.

If you follow these tips, you will get better results. Your parts will have the right shape, size, and surface finish. You will also waste less material and save time on rework.

PTFE Grades & Fillers

Virgin vs. Filled

When you pick PTFE, you must choose virgin or filled grades. Virgin PTFE is pure and has nothing added. It gives great chemical resistance and works in hot or cold places. People use virgin PTFE for gaskets, bellows, and parts that touch food or medicine. This is because it meets strict safety rules.

Filled PTFE has things like glass, carbon, bronze, or molybdenum disulfide mixed in. These fillers change how PTFE acts. They make it stronger and harder. Filled PTFE does not bend as much under pressure. It also lasts longer and wears out less than virgin PTFE. For example, bronze or glass can make it wear better by up to 1,000 times. They also help it not grow or shrink as much with heat. Filled PTFE works better for tough jobs like seals, bearings, and machine parts.

| Grade Description | Color | Temperature Range (°F) | Tensile Strength (PSI) |

|---|---|---|---|

| Virgin PTFE | White | -450 to 600 | 4675 |

| Modified PTFE | White | -450 to 600 | 5100 |

| Lubricated Carbon-Filled PTFE | Grey/Black | -450 to 600 | 2310–3210 |

| Lubricated Glass-Filled PTFE | Light Grey | -450 to 600 | 2525 |

Tip: Pick virgin PTFE for chemical safety and purity. Use filled PTFE if you need more strength or wear resistance.

Common Fillers

You can pick from many fillers to fit your needs:

- Glass Fiber: Makes PTFE stronger and tougher. It helps the part stay the same shape under weight. Good for bearings and seals.

- Carbon: Helps PTFE last longer and move heat better. It is good for parts that move a lot.

- Graphite: Makes PTFE more slippery and self-lubricating. This is great for sliding or spinning parts.

- Bronze: Helps PTFE resist wear and move heat. It also keeps the part from bending. Works well in hydraulic systems.

- Molybdenum Disulfide (MoS₂): Makes PTFE harder and even more slippery. It helps when you need dry lubrication and high pressure.

- Polyimide: Makes PTFE stronger and helps it handle heat. It also helps the part last longer.

Each filler changes PTFE in its own way:

- Glass filler helps PTFE not grow or shrink with heat. It also makes it stronger when squeezed.

- Carbon filler helps PTFE move heat and not bend.

- Graphite filler makes PTFE more slippery and helps it last longer.

- Bronze filler helps PTFE wear less and move heat better.

🛠️ Note: Fillers can help PTFE not bend by up to 10 times. This makes your parts last longer.

Grade Selection

To pick the right PTFE grade, think about what your part needs. Ask yourself:

- Do you need it to resist chemicals or be safe for food?

- Will your part face lots of pressure, heat, or movement?

- Is it most important that it does not wear out or change size?

Use this table to match fillers to your needs:

| PTFE Filler Type | Performance Benefits | Ideal Applications |

|---|---|---|

| Glass Fiber | Strength, durability, stability | Bearings, gaskets, seals |

| Molybdenum Disulfide | Hardness, low friction, wear resistance | Piston rings, seals |

| Graphite | Self-lubrication, low friction | Bearings, gaskets |

| Bronze | Wear resistance, thermal conductivity | Valve seats, liners |

| Polyimide | High strength, thermal stability | Compressor rings, piston rings |

| Stainless Steel | High temperature, load bearing | Gaskets, valve seats |

Tip: Always talk to your machining partner or supplier. They can help you pick the best PTFE grade and filler for your job.

If you know the difference between virgin and filled PTFE, and what each filler does, you can pick the best grade. This helps your parts work better and last longer.

Surface Finish & Post-Processing

Finish Ranges

You want your PTFE parts to be smooth and work well. The surface finish is important for sealing, sliding, and how it looks. Most PTFE parts have a roughness between Ra 0.8 and 3.2 micrometers. Some seals or medical parts need a finish as fine as Ra 0.4 micrometers. If you want it smoother, you can polish or buff the part after machining.

| Application | Typical Surface Finish (Ra, µm) |

|---|---|

| General Components | 1.6 – 3.2 |

| Seals & Gaskets | 0.8 – 1.6 |

| Medical Devices | 0.4 – 0.8 |

Tip: Always know what finish you need before starting. This helps you pick the right tools and steps.

Improvement Techniques

You can make PTFE parts smoother by using the right methods. Start with sharp, uncoated carbide tools. Use a low feed rate and a high cutting speed for a better cut. After machining, polish the part with fine abrasives or a buffing wheel. For very smooth parts, try lapping or chemical polishing.

Here are some ways to get a better finish: Use sharp tools and change them often. Lower the feed rate for the last pass. Polish or buff the part after machining. Use lapping for the smoothest finish. Clean the part before and after polishing to remove dust.

AFI Industrial uses advanced CNC machines and skilled workers to control each step. Their team checks the CNC programs and watches the process to keep the size and surface quality right. They look for burrs, scratches, and other problems during and after machining. They check sizes with Keyence and CMM machines, and record all data for tracking.

Cleaning & Inspection

You must clean PTFE parts well to remove dust, chips, and leftover bits. Use soft brushes, compressed air, or lint-free wipes. Do not use harsh chemicals that could hurt the surface. After cleaning, check the parts under bright light (at least 500 lux) and UV light to find any marks or dirt. Surfaces should look clean from one meter away, with no marks you can see.

Quality teams at AFI Industrial follow strict routines: They do daily checks for surface problems. Each week, they test samples for leftover dirt. Every month, they check equipment based on risk. They use control charts and Pareto analysis to track cleaning results. For medical or food parts, they do germ checks using USP <1111> rules. All cleaning and checks are written down and follow ALCOA+ data rules.

If you find a problem, you must look into it and fix it before shipping. AFI Industrial checks every part and uses CMM machines to make sure each one is good. You can trust your PTFE parts will be clean, smooth, and ready to use.

Cost & Efficiency

Cost Factors

When you want to machine PTFE, you need to know what makes it cost more. PTFE costs more than many other plastics. The material price is two to three times higher than regular plastics. You also need special tools and slower cutting speeds. PTFE is soft and can bend or get hot fast. These things make each part take longer and cost more.

A PTFE part usually costs between $20 and $50. This is because it needs to resist chemicals and have tight sizes. Machining PTFE wears out tools quickly, so you must change them often. Checking the parts and heat treating them also adds to the price, especially if you need very exact parts.

If you look at PTFE and UHMWPE, PTFE needs more careful work. PTFE is soft and gets hot easily, so you need special machines and skilled workers. These needs make the total cost go up.

Reducing Waste

You can waste less and work better by using smart designs and good machining steps. Keep your part shapes simple. Make walls at least 0.5 mm thick and do not use deep holes with sharp corners. Try to have fewer setups and checks. These ideas save time and material.

Here are some ways to waste less:

- Use CNC machining for exact and repeatable parts. This helps you avoid mistakes and save material.

- Set the right cutting speed and feed rate. Faster, controlled cutting makes tools last longer and makes less scrap.

- Pick normal tolerances (±0.13mm) for most parts. Only use tight tolerances (±0.05mm) when you really need them.

- Plan tool paths with good software. This cuts down on extra moves and helps tools last longer.

- Cut parts a little bigger, then let them rest before finishing. This keeps sizes right and means less fixing later.

🛠️ Tip: Try to design your parts for 3-axis machining. Fewer setups mean fewer mistakes and lower costs.

Balancing Quality

You want good PTFE parts but do not want to spend too much. To do this, you must balance quality and saving money. Use CNC machines to get the same results every time and waste less material. Keep your work area cool to stop parts from bending and keep sizes right.

The table below shows important ways to balance quality and cost:

| Benchmark Aspect | Description & Impact |

|---|---|

| CNC Machining | Gives exact parts and wastes less, so you control quality and cost. |

| Thermal Management | Stops parts from bending and keeps sizes right. |

| Specialized Tooling | Sharp carbide tools and soft clamps stop bending and lower setup costs. |

| Design Optimization | Use normal tolerances and bigger batches to save money and work faster. |

| Process Control | Controlling temperature and checking with CMM keeps quality high without extra cost. |

Batch size matters too. Making more parts at once lowers the cost for each one. Small batches or samples can cost three to five times more per part. Always match your quality needs to your budget by picking the right tolerances, batch sizes, and checks.

Note: Good planning and smart designs help you get the most for your money when machining PTFE.

Applications

Key Industries

You can find Teflon (PTFE) parts in many important industries. These industries need parts that work well and last a long time. PTFE is special because it does not react with chemicals, is slippery, and can handle hot and cold. That is why it is used for important jobs. Here are some main industries that use Teflon parts:

- Aerospace: People use PTFE for fuel hoses and electrical parts. It is also used for small, exact pieces that need to be smooth and work every time.

- Medical: Doctors and hospitals pick PTFE for safe parts like valves and implants. It is also used for seals that must be very clean and safe for people.

- Automotive: Car makers use PTFE in gears, seals, and bushings. These parts move a lot and get hot, so they need to last.

- Food Processing: Machines that touch food use PTFE to keep things clean and safe. It helps meet food safety rules.

- Industrial Equipment: Factories use PTFE in pumps and machines that work with chemicals. It helps the machines last longer and not break down.

PTFE works well in these areas because it is strong and can do many jobs.

When to Use Teflon

Pick Teflon when you need a part that can handle hard jobs and needs to be made very carefully. PTFE is a good choice for many reasons:

- It is very slippery, so parts do not wear out fast.

- PTFE does not react with most chemicals or cleaners.

- It works in very hot or very cold places, from -328°F to 500°F.

- PTFE is great for electrical parts because it does not let electricity pass through.

- It keeps its shape even when it gets hot or cold.

- PTFE is safe for people and food because it is non-toxic.

Use PTFE for seals, gaskets, and bearings that need to last a long time. It is also good for parts that must be very smooth and fit just right. If your part needs to be strong and work in tough places, PTFE is a smart pick.

Case Studies

You can see how PTFE helps in real projects. Here are some examples:

- Gear Pump Bearings: Engineers wanted pumps that were quiet and smooth. They used PTFE to make bushings with a tight size of 0.015 mm and a smooth inside. The pumps made less noise and lasted longer than ones with bronze parts.

- Scroll Compressor Bearings: Air conditioners and car coolers need very exact bearings. PTFE bearings gave the right fit and lasted a long time, even when rules and pressures changed.

- Food Processing Equipment: Factories use PTFE in mixers and belts to keep food safe. The smooth surface stops food from sticking and makes cleaning easy.

AFI Industrial helps with every step, from design to shipping. You get strong, clean PTFE parts that fit your needs. This saves you time and money on your projects.

If you want to do well with machining parts teflon material, first learn about PTFE’s main properties. Pick the best tools and settings for every job. Work with skilled companies like AFI Industrial to get good quality and exact parts. Always use smart steps to save money and get results you can trust. For hard projects, ask experts for help or look for more information.

FAQ

Use sharp carbide or diamond tools for PTFE. These tools cut clean and last longer. Always check your tools before you start a job.

Keep cutting speeds low and use air or mist to cool. Clamp parts gently with soft jaws. Let the parts rest after cutting so they keep their shape.

Yes, you can get tolerances as close as ±0.05 mm. Use advanced CNC machines and measure after the parts cool. AFI Industrial checks sizes with CMM for accuracy.

Clean PTFE parts with soft brushes, air, or lint-free wipes. Do not use strong chemicals. Check the parts under bright light to make sure they are clean.

Pick filled PTFE if you need more strength or wear resistance. Use virgin PTFE for chemical safety and purity, like in food or medical parts.

Design simple shapes and use CNC machines for accuracy. Plan tool paths well and use normal tolerances when you can. This saves material and lowers costs.

Industries like aerospace, medical, automotive, food, and chemical use PTFE parts. PTFE gives good results in tough places.

🛠️ Tip: Always ask your machining partner about the best PTFE grade and process for your job.