Gear Hobbing

We offer hobbing manufacturing services for a wide range of industries, so contact us if you need to get precise custom gear manufacturing. High precision gear hobbing processing, for your mechanical transmission system to provide reliable protection!

Custom CNC Gear Hobbing

AFI Industrial Co., Ltd. uses advanced equipment and a professional technical team to customize high-precision hobbling parts with various materials for customers. These gear parts are widely used in automobile manufacturing, aerospace, and different fields of life and can meet customers’ needs in all aspects.

Gear Hobbing Workshop

Precision equipment can provide customers with quality gear parts.

GearHobbing Process

Gear hobbing is the preferred process for making gear parts. It can not only quickly mass produce, but also ensure the stable quality of the gears produced.

Gear Hobbing Products

High precision hobbing and good surface quality can meet the quality needs of customers.

Hobbing Inspection

Precise inspection equipment and professional personnel ensure that customers get high-quality products.

Gear Hobbing Services

AFI Industrial Co., Ltd. specializes in customized gear production, equipped with imported CNC gear grinding machines (with processing accuracy reaching DIN grade 4) and three-coordinate measuring instruments, capable of manufacturing various precision gears with modules ranging from 0.5 to 20mm.

We have a team of engineers with over 15 years of experience and adopt advanced carburizing and quenching processes (surface hardness HRC58-62, core hardness HRC30-35) to ensure the wear resistance and fatigue resistance of our products. We support minimum orders of 1 piece or mass production, providing cost-effective gear customization solutions for industries such as automobiles, machinery, and automation equipment.

Precision Gear Hobbing

AFI Industrial Co., LTD., relying on advanced mechanical equipment and a professional technical team, specializes in various precision gear hobbing processing. The size and shape accuracy of the gears we produce for our customers have reached the industry-leading level. Their surfaces are smooth, which can reduce wear and extend service life. Under the guarantee of high precision and high quality, gear transmission has high efficiency and smooth operation. They are widely used in aerospace, the electronics industry, and other fields, and are deeply trusted by customers.

Sample Development of Gear Hobbing

AFI Industrial Co., Ltd. provides its customers with rapid prototyping and CNC gear hobbing services to help them achieve sample development. Our prototyping capabilities are ideal for designers and engineers, allowing customers to quickly test and improve designs, helping customers to release new products in the shortest possible time, thereby leading the market.

Custom Gear Cutting and Making

Our engineers will be based on the specific needs of customers, and the precise design of the gear planning. During the cutting process, the precision is strictly controlled within a very small tolerance range to ensure that the parameters of the gear module, pressure Angle, tooth thickness, and so on fully meet the design requirements.

Gear Grinding Process

Our grinding process is a procedure carried out after gears have undergone early processes such as cutting and forming. It has extremely high precision requirements, which can reduce the surface roughness of gears, decrease the friction and wear between teeth, thereby extending the service life of gears and providing customers with perfect products.

Custom Precision Hobbing

Custom precision gear hobbing parts are key components carefully crafted to meet the specific needs of customers. AFI Industrial Co., Ltd. uses advanced technology and strictly controls every detail to ensure that gear parts are accurate in size and smooth in surface to meet the stringent requirements of complex engineering. It provides reliable support for various equipment and instruments that use gears and improves their overall performance.

Hobbing Drawings

After receiving the customer’s drawings, our technical team will conduct a drawing review and process planning to ensure that each processing link meets the requirements of the drawings, and the product size accuracy is controlled within ±0.01mm. Our quality control system ensures that the mass-produced products are consistent with the samples and meet all the technical requirements of customers.

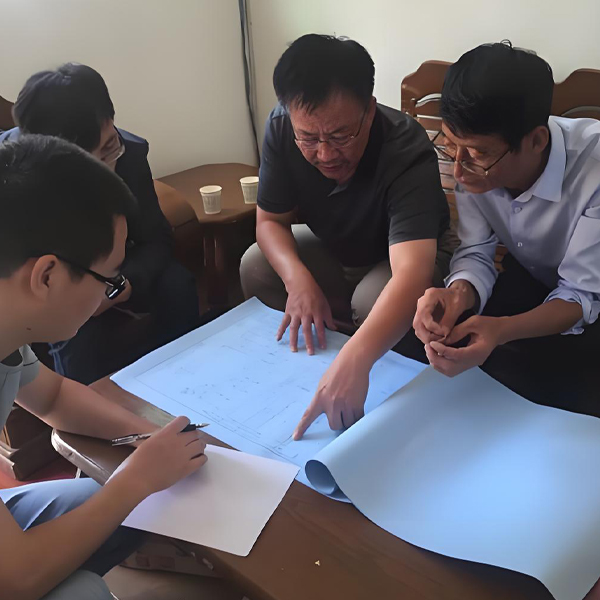

Engineer Analysis Drawing

The engineering team carried out three-dimensional tolerance analysis based on the GD&T standard. They selected the base material in combination with the ASTM material database, optimized the technical parameters through CAM programming, and simultaneously formulated the three-coordinate inspection procedures to ensure the control of μ -level form and position tolerances.

Gear Hobbing

Our technical team, relying on years of processing experience, strictly adheres to standardized process flows and uses intelligent numerical control systems to precisely control processing parameters, ensuring that each product meets the dimensional accuracy and surface finish requirements of the drawings, providing customers with stable and reliable precision parts processing services.

Hobbing Inspection

From incoming material to the manufacturing process to delivery, quality inspection personnel test the products according to the drawings to ensure that the products fully meet the quality requirements of customers.

Custom Gear Products Materials

AFI Industrial Co., Ltd. offers its customers products in a wide range of materials. Whether it is necessary to process steel, aluminum, copper, and other metal materials to meet the needs of high strength and durability; Or use plastic, such as nylon, PVC, etc., to achieve lightweight and special performance; Or for other special materials with specific requirements, we can rely on advanced technology and professional team, tailor-made for you to meet the quality needs of customers.

The density of aluminium alloy is only one third that of steel, and it has excellent processing performance. It is widely used in aerospace, the automotive industry and precision instruments, and other fields.

- 2024

- 6061

- 7075

Copper has good wear resistance and anti-friction, suitable for some special requirements of the gear, such as instrument gear.

- Copper

- brass

- bronze

Steel is a metallic material mainly made of iron, with some carbon and other elements added to it, such as manganese, chromium, vanadium, and the like. This material not only has high strength but is also very durable and affordable. It is applied in key fields such as building structures, mechanical manufacturing, the automotive industry, and energy equipment. It can be said to be an important basic material in modern industry.

- Carbon steel

- Alloy steel

- Cast iron

Stainless steel, with its corrosion resistance and hygiene performance, has become the material choice for medical devices, food processing equipment, and catering utensils. Stainless steel has a high surface finish and is easy to disinfect, effectively meeting the requirements of hygiene standards.

- SUS304

- SUS316

- SUS303

Plastic is a lightweight, economical, and multi-functional material, which has waterproof performance and electrical insulation properties. Its excellent plasticity enables it to be formed into complex components through various processing methods. Meanwhile, it has satisfactory durability and is applied in fields such as packaging, electronics, and building materials.

- POM

- PA

- PPS

- PC

Custom Surface Treatment

AFI Industrial Co., Ltd. provides its customers with customized gear machining and surface treatment services to improve the performance and service life of gears. The specific surface treatment method should be selected according to the use requirements of the gear, working environment, and materials. Whether you need anodizing, electroplating, or surface treatment for other projects, our expertise adds value to your parts to meet the quality requirements of your products.

Rolling reinforcement can make the gear surface more smooth and flatter, reduce surface roughness, enhance surface hardness, improve fatigue performance, improve dimensional accuracy, and strengthen material properties.

Nitriding treatment can enhance the surface hardness (HV≥800) and wear resistance of gears, increase fatigue strength by more than 30%, while improving corrosion resistance and maintaining dimensional stability (deformation ≤0.02mm), and the surface roughness can be reduced to Ra0.4μm or less.

Induction hardening can improve the surface hardness and wear resistance of the gear, and enhance the fatigue strength. This method has fast heating speed, short time, and less oxidation and decarbonization of the gear.

Electroplating can improve the corrosion resistance and wear resistance of the gear, make its surface smooth and bright, and improve the conductive energy of the gear.

Chemical planting ance the wear resistance of gears, reduce the coefficient of friction, and increase the fatigue strength of products, etc. The surface treatment of this kind of gear is widely used in aerospace, automotive, mechanical and other fields.

Shot peening results in plastic deformation of the gear surface, which increases gear surface hardness, enhances fatigue strength and reduces gear surface roughness.

Carburizing makes the gear surface rich in carbon elements, which can improve the hard bottom and wear resistance of the gear surface, enhance fatigue strength, maintain the toughness of the heart, and have excellent comprehensive mechanical properties.

Mass Production

AFI Industrial Co., Ltd. has a complete vertical/horizontal gear hobbing processing system and adopts a unique process control system, which can achieve stable output with DIN grade 6 precision within the diameter range of Φ10-800mm. Especially in the module range of 0.5-12mm, our innovatively developed rapid change-over system can shorten the delivery cycle of small-batch orders (minimum 1 piece) by 60%, while maintaining a tolerance control of ±0.01mm, providing you with reliable and stable gear matching solutions!

Dimensional Tolerance

To ensure the quality of hobbing machining, AFI Industrial Co., Ltd. needs to strictly control product tolerances in the machining process, including gear size tolerances, tooth shape tolerances, tooth direction tolerances, radial runout tolerances, tooth spacing deviations, etc. We will choose the appropriate tolerances according to different gear uses and accuracy requirements, combined with customer drawings, to meet customer product needs.

How to Start Your Order

Send your drawings

Process discussion, quotation

Make a sample

Volume produce

Shipment & Payment

Shipping

Checkout

AFI Industrial Co., Ltd. has established a quality management system for CNC parts, equipped with professional testing equipment and a senior quality inspection team. We conduct all-round inspections at every stage by the customer’s drawings and technical standards to ensure that all products meet 100% of the customer’s quality requirements and industry standards.

Shipment

AFI Industrial Co., Ltd. collaborates with many well-known logistics partners worldwide. We will carefully package your products based on their characteristics and requirements, and then select the most cost-effective and fastest transportation plan for you to ensure the safe and punctual delivery of your goods.

Our Promise

With our services, you will get a trusted supplier. In the coming days, we will continue to improve our professional degree, expand our credibility, and let you get the following harvest!

Quality Guarantee

We offer comprehensive inspections to ensure that the dimensions are accurate and the appearance meets the customer’s specifications during the gear hobbing process.

Quick Response

After receiving the order, we respond quickly within 2 hours, quote within 4 hours, and deliver according to quantity within 3-15 days.

Custom Material

We will according to the needs of customers, carefully select high-quality raw materials, customized to meet customer needs for all kinds of products.

Custom Surface Treatment

We can apply a variety of surface treatments to manufactured products according to customer requirements, including electroplating, anodizing, etc.

Arbitrary Size

We can produce products strictly in accordance with the dimensions on the drawings provided by customers, ensuring that every dimension is precise and error-free, fully meeting the quality standards.

Unlimited Quantity

Whether you need samples or mass production, we can precisely manufacture according to your requirements, ensuring that the quality of each product remains consistent.

Brand We Cooperated with

AFI Industrial Co., Ltd. has specialized in precision parts processing for 15 years and possesses multiple high-precision five-axis turning centers. We have passed the ISO9001 quality system certification. We have long been providing key components for the automotive and home appliance industries. We have rich mass production experience in products such as transmission valve bodies and heat dissipation components. Our product quality is stable and reliable, with a defect rate controlled below 0.05%.

Frequent Asked Questions

Gear hobbing is the principle of generating a method to process gears. Using the hob to process the opposite wheel is equivalent to the meshing of the helical cylindrical gear pair.

Hobbing processing is carried out based on the meshing principle of helical gears. The hob is like a helical gear, meshing with the gear being processed at a certain transmission ratio. While the hob rotates, it feeds along the axis of the gear, gradually cutting out the tooth profile of the gear.

The gear shaping machine processes based on the meshing principle of a pair of cylindrical gears. It is equivalent to a gear, meshing with the gear without clearance while moving up and down. The cutting edge of the gear shaping tool cuts out a tooth groove of the gear in each reciprocating motion. After multiple insertions, a complete gear tooth profile is gradually formed.

The advantages of gear hobbing processing include: high precision, high production efficiency, wide application range, and long tool life. It is easy to achieve automated production.