Metal Stamping

Choose AFI Industrial Co., Ltd.’s metal stamping to start the journey of efficient production and create a better future!

Metal stamping can quickly produce large quantities of parts, quickly respond to customer order needs, and shorten customer procurement cycles.

Stamping dies can produce high-precision products and ensure the stability of quality, better meet customer requirements for product quality and performance, and help customers occupy the absolute market advantage with high-quality products.

We can produce stamping parts made of stainless steel, copper, aluminum, iron and other materials, suitable for automotive, aerospace, electronics, home appliances and industrial applications, to meet the needs of customers in different industries

Custom Precision Stamping

AFI Industrial Co., Ltd. has more than 100 stamping processing machines. Focusing on custom metal stamping parts, we use advanced technology and a professional team to create high-quality stamping products that meet customers’ needs in various fields.

Stamping Workshop

Professional stamping technologies can be customized to a variety of stamping metal parts.

Metal Stamping

The metal stamping process is the use of a mold and stamping equipment to exert pressure on the metal sheet so that it is deformed into a part with a fixed shape.

Stamping Parts

Stamping parts have a fast mass production speed, stable quality, and exquisite product appearance, which can meet the various needs of customers.

Stamping Inspection

Precise inspection equipment and professional personnel ensure that customers get high-quality products.

Custom Metal Stamping Service

AFI Industrial Co., Ltd., as a professional metal stamping service provider, adopts stamping equipment and precision die technology to offer customers comprehensive stamping customization solutions.

We are equipped with stamping equipment, which can ensure the precision stamping of products (±0.03mm tolerance) and the development of complex molds (minimum R Angle 0.1mm), meeting the production requirements of various precision stamping parts. Meanwhile, we have a mold R&D team that can customize and develop complex-shaped stamping molds according to customer needs. The mold life is 500,000 stamping times, which increases the mold service life by more than 30% and helps customers reduce production costs.

In terms of production management, we have established a quality control system. We implement full-process quality monitoring from raw materials entering the factory to finished products leaving the warehouse to ensure that the product qualification rate reaches over 99.8%. Whether it’s a minimum order of 1 piece or mass production, we can handle it all and provide you with satisfactory service.

Precision Stamping

AFI Industrial Co., Ltd.’s precision metal stamping uses stamping dies and stamping equipment to apply pressure to sheet metal, strip, pipe, etc., to produce plastic deformation or separation to obtain the desired shape and size of the part. Stamping parts have high precision, low consumption, and high production efficiency, and can be widely used in automobile body parts, electrical shells, hardware tools, and other fields. It can meet the processing needs of customers for different products.

Sample Development of Stamping Parts

Customers take advantage of AFI Industrial Co., Ltd’s rapid prototyping metal stamping service, which allows them to provide sample development. Perfect for designers and engineers, our prototyping capabilities allow you to quickly test and improve designs, helping you get a head start on the market by releasing new products in the shortest time possible.

Custom Precision Stamping Parts

Custom precision stamping is a key component crafted to meet specific needs. AFI Industrial Co., Ltd. uses advanced stamping technology to press parts of various shapes with high precision and low consumption using molds and stamping tools of different shapes. It can meet the strict requirements of complex engineering, provide reliable support for various types of equipment, and improve overall performance. Meet the needs of customers for products.

CNC Turning Drawings

After receiving the customer’s drawings, our technical team will conduct a drawing review and process planning to ensure that each processing link meets the requirements of the drawings, and the product size accuracy is controlled within ±0.01mm. Our quality control system ensures that the mass-produced products are consistent with the samples and meet all the technical requirements of customers.

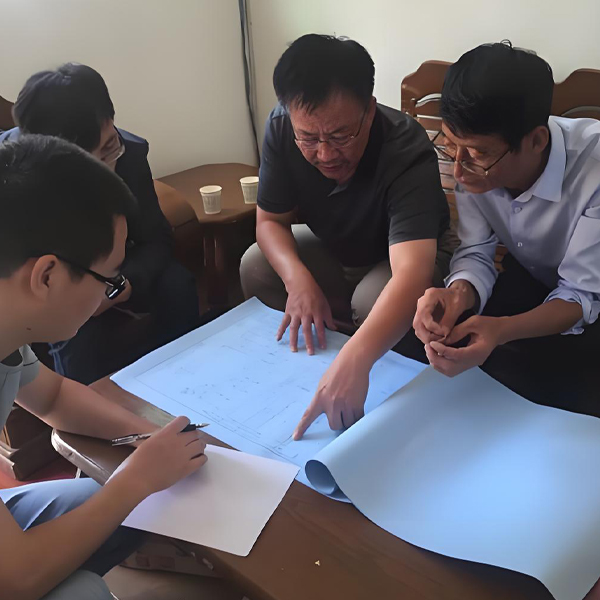

Engineer Analysis Drawing

The engineering team carried out three-dimensional tolerance analysis based on the GD&T standard. They selected the base material in combination with the ASTM material database, optimized the technical parameters through CAM programming, and simultaneously formulated the three-coordinate inspection procedures to ensure the control of μ -level form and position tolerances.

Sheet Metal Stamping

Our technical team, relying on years of processing experience, strictly adheres to standardized process flows and uses intelligent numerical control systems to precisely control processing parameters, ensuring that each product meets the dimensional accuracy and surface finish requirements of the drawings, providing customers with stable and reliable precision parts processing services.

Stamping Parts Inspection

From incoming material to the manufacturing process to delivery, quality inspection personnel test the products according to the drawings to ensure that the products fully meet the quality requirements of customers.

Custom Stamping Materials

AFI Industrial Co., Ltd. offers customers a wide range of stamping materials. There are light corrosion-resistant stamping aluminum, stamping brass with unique texture, durable stamping steel, stamping stainless steel with excellent performance, etc. In addition to providing exquisite stamping craft materials. Whether your needs are for industrial manufacturing or artistic creation, we can rely on advanced technology and professional teams, tailored to meet the quality needs of customers.

Aluminum is light but strong, with excellent machinability and corrosion resistance. Ideal for aerospace and automotive components.

- 1050

- 1060

- 3003

- 3A21

- 5052

- 5083

- 6061

- 7075

Brass is a copper-zinc alloy that has good machinability and corrosion resistance and is often used in stamping.

- H62

- H65

- lead brass

- tin brass

- aluminum brass

Copper has excellent electrical and thermal conductivity. It has high ductility and toughness and can be processed into products of various shapes through multiple methods. It is widely used in fields such as mechanical manufacturing, the electronics industry, and construction.

- C101(T2)

- C103(T1)

- C103(TU2)

- C110(TU0)

- Beryllium copper

Bronze is an alloy made from the metals copper and tin, with a lower admixture of other elements such as lead and aluminium. It possesses high wear resistance, corrosion resistance, casting performance , and anti-friction properties. It has been widely used in mechanical manufacture, shipping, building materials, construction, bridge construction, architectural decoration, art, electrical appliances , and so on industry departments, and is also an important engineering and artistic material.

- Tin bronze

- aluminum bronze

- lead bronze

Steel is a metallic material mainly made of iron, with some carbon and other elements added to it, such as manganese, chromium, vanadium and the like. This material not only has high strength but is also very durable and affordable. It is applied in key fields such as building structures, mechanical manufacturing, the automotive industry, and energy equipment. It can be said to be an important basic material in modern industry.

- mild steel

- medium carbon steel

- electrical steel sheet

Alloy materials, through optimized composition ratios and heat treatment processes, possess high strength, heat resistance, and corrosion resistance. They are applied in high-end manufacturing fields such as aerospace engine components, chemical corrosion-resistant equipment, and key components of precision machinery, meeting the usage requirements under harsh working conditions. It usually has the following kinds of alloys:

- aluminum alloy

- copper alloy

- titanium alloy

- magnesium alloy

Stainless steel, with its corrosion resistance and hygiene performance, has become the material choice for medical devices, food processing equipment, and catering utensils. Stainless steel has a high surface finish and is easy to disinfect, effectively meeting the requirements of hygiene standards.

- SUS201

- SUS304

- SUS316

- SUS301

- SUS430

Stainless steel is known for its corrosion resistance, making it the first choice for medical equipment and food processing equipment.

- SUS201

- SUS 304

- SUS316L

- SUS440C

- SUS303

- SUS316

- SUS420

- SUS430

- AISI 304

- SUS630/17-4PH

- SUS431

CNC turning wood is easy to process, the material is light and strong, and it is a good heat insulation and electrical insulation materialhogany.

- camphor wood

- Chinese fir

- yellow pineapple wood

- Liu An wood

- basswood

- oak

- catalpa wood

There are many kinds of stone that can be used for processing, which are widely used in construction, decoration, engraving and other fields.

- marble

- granite

- limestone

- artificial stone

Custom Surface Treatment

AFI Industrial Co., Ltd. provides surface treatments for custom precision metal stamping services. Whether you need anodizing, electroplating, or surface treatment for other projects, our expertise adds value to your parts to meet the quality requirements of your products.

Anodizing: Our technicians immerse metal products in electrolytes such as sulfuric acid, chromic acid, or oxalic acid. The surface of the products undergoes an oxidation reaction, forming an oxide film, thereby completing the anodic oxidation reaction of the products. This surface treatment is mainly used for aluminium and its alloys, and can also be applied to metals such as titanium and magnesium. It can enhance the corrosion resistance and wear resistance of the product. We offer customers a variety of color options to meet the diverse appearance requirements of the product. Anodizing processes are widely applied in fields such as aerospace, the automotive industry, architectural decoration, consumer electronics casings, and medical devices.

Electroplating is a process that uses the principle of electrolysis to deposit a layer of metal or alloy on the surface of metals or other materials. Its coating can effectively isolate air and moisture, and its salt spray resistance test can reach 500 to 1000 hours. The wear resistance is improved by 3 to 5 times, helping customers extend the service life of components.

Our coating thickness is controllable within 5-50μm, with a tolerance of ±1.5μm. We offer various process solutions such as galvanizing, nickel plating, and chromium plating.

We can provide customized electroplating solutions based on your product requirements to help you increase the added value and market competitiveness of your products.

Spraying is a commonly used surface treatment technology. There are various spraying methods, air spraying with its flexible operation, high coating quality, and low cost advantages, is widely used in automobiles, air tools, electrical equipment, and other areas of hardware parts.

Brushed is a surface treatment method that forms lines on the surface of the workpiece by grinding the product to play a decorative effect. Because the surface drawing treatment can reflect the texture of metal materials, it has been loved by more and more users and is more and more widely used.

Sandblasting is a process for surface treatment of workpieces. The compressed air is used as the power to form a high-speed jet beam to spray the spray material (copper ore, quartz sand, emery, iron sand, sea sand) to the surface of the workpiece to be treated at high speed so that the appearance or shape of the workpiece surface is changed.

Polishing is a process that removes microscopic protrusions on the surface of materials through physical, chemical or electrochemical methods, making them smooth, flat or even achieving a mirror-like effect. It is widely used in fields such as precision parts processing, automobiles, and medical equipment.

Mass Production

AFI Industrial Co., Ltd. has advanced automatic metal stamping equipment and a professional technical team. Whether it is precision electronic stamping parts or strong mechanical stamping parts, we can accurately manufacture them. Whether it is a small batch of custom orders or a large batch of production tasks, they can be efficiently completed. We understand our customers’ time requirements for mass production and efficiently arrange production schedules to ensure timely delivery. Working with us, you’ll get reliable products, quality service, and efficient production solutions to help your business thrive.

Dimensional Tolerance

The tolerance range of AFI Industrial metal stamping parts usually varies according to different accuracy requirements and material thickness. Under normal circumstances, the tolerance range of stamping parts is between ±0.5mm and ±2.0mm. Specifically, the tolerance range of flat stamping parts is generally between ±0.1mm and ±0.5mm, while the tolerance range of formed stamping parts is between ±0.2mm and ±1.0mm. The company will also ensure that all product dimensions are within tolerances according to the accuracy of the customer’s drawings. To ensure that products meet customer quality requirements.

How to Start Your Order

Send your drawings

Process discussion, quotation

Make a sample

Volume produce

Shipment & Payment

Shipping

Checkout

AFI Industrial Co., Ltd has established a quality management system for CNC parts, equipped with professional testing equipment and a senior quality inspection team. We conduct all-round inspections at every stage by the customer’s drawings and technical standards to ensure that all products meet 100% of the customer’s quality requirements and industry standards.

Shipment

AFI Industrial Co., Ltd. collaborates with many well-known logistics partners worldwide. We will carefully package your products based on their characteristics and requirements, and then select the most cost-effective and fastest transportation plan for you to ensure the safe and punctual delivery of your goods.

Our Promise

With our services, you will get a trusted supplier. In the coming days, we will continue to improve our professional degree, expand our credibility, and let you get the following harvest!

Quality Guarantee

We offer comprehensive inspections to ensure that the dimensions are accurate and the appearance meets the customer’s specifications during the stamping process.

Quick Response

After receiving the order, we respond quickly within 2 hours, quote within 4 hours, and deliver according to quantity within 3-15 days.

Custom Material

We will according to the needs of customers, carefully select high-quality raw materials, customized to meet customer needs for all kinds of products.

Custom Surface Treatment

We can apply a variety of surface treatments to manufactured products according to customer requirements, including electroplating, anodizing, etc.

Arbitrary Size

We can produce products strictly in accordance with the dimensions on the drawings provided by customers, ensuring that every dimension is precise and error-free, fully meeting the quality standards.

Unlimited Quantity

Whether you need samples or mass production, we can precisely manufacture according to your requirements, ensuring that the quality of each product remains consistent.

Brand We Cooperated with

AFI Industrial Co., Ltd. has specialized in precision parts processing for 15 years and possesses multiple high-precision five-axis turning centers. We have passed the ISO9001 quality system certification. We have long been providing key components for the automotive and home appliance industries. We have rich mass production experience in products such as transmission valve bodies and heat dissipation components. Our product quality is stable and reliable, with a defect rate controlled below 0.05%.

Frequent Asked Questions

Metal stamping, as a mechanical processing and manufacturing process, achieves efficient and precise forming of metal sheets through advanced die technology and automated equipment, providing customers with high-quality metal parts. Its dimensional tolerance can be controlled within ±0.05mm, meeting the precision assembly requirements of customers and supporting various forming processes such as blanking, bending, stretching, and flanging.

The common stamping materials we see include: carbon steel (SPCC), stainless steel (SUS304), aluminum alloy (5052), copper alloy (H62), etc. When choosing materials, strength, corrosion resistance, cost, and subsequent processes (such as electroplating/spraying) should be taken into consideration. For special requirements, titanium alloy or high-strength steel can be selected.

The metal stamping process has three core advantages: high efficiency, high precision, and low cost. It adopts automated stamping equipment to achieve a production speed of 60 to 120 pieces per minute. The tolerance size can be controlled within ±0.05mm, which is suitable for mass production and helps customers shorten the production cycle.

Its molds can be reused after being developed once, and the cost per piece decreases significantly as the output increases. At the same time, it also supports the processing of various metal materials with thicknesses ranging from 0.1 to 6mm, and can be integrally formed into complex geometric shapes, reducing the subsequent assembly procedures for customers.

Metal stamping is widely applied in many fields, such as body and chassis parts in automotive manufacturing, connectors and shielding covers in electronics and electrical appliances, surgical instruments and implant casings in medical devices, inner linings and structural components in household appliances, as well as precision parts in the aerospace industry.

We can select appropriate materials based on the characteristics of products in each industry. For instance, high-strength steel is commonly used in the automotive industry, while copper alloys and aluminum alloys are preferred in the electronics industry.

When choosing a metal stamping manufacturer, you need to consider their experience, capabilities, and quality control processes while being able to meet your specific requirements and project timeline. AFI Industrial has experienced product engineers and tooling engineers who can design and build the tooling configurations that will save you the most material for your products and save you money on your purchases.

Our professional production staff and hundreds of presses can respond to your needs as quickly as possible and produce large quantities of products in the shortest possible time. We have a perfect quality control system with standardized inspections at every step from incoming material to finished product shipment to ensure that every product received by our customers is qualified.

Metal stamping parts are used in various industries such as automotive, electronics home appliances, etc. As metal parts of end products in various industries, their quality directly affects the functionality, reliability, and durability of customers’ end products.

The quality of a metal stamped part can be affected by a variety of factors, including the type and quality of materials used, the design and accuracy of the stamping die, the expertise and experience of the stamping manufacturer, and the production processes and equipment used.

Using low quality metal stamping parts can lead to product failures, safety hazards, and increased costs for your company. It can also damage a company’s reputation, leading to customer dissatisfaction and potential legal issues. Therefore, it is important to prioritize high-quality stamped parts to avoid these consequences.

As a manufacturer with more than ten years of experience in metal stamping products, we have standardized evaluation and implementation plans for materials, personnel, equipment, and processes required for stamping products. We regularly inspect and maintain our stamping equipment, train and evaluate the work skills and attitudes of our technicians, and implement stringent quality control measures throughout the entire production process to ensure that we can provide our customers with consistent and high quality products for our customers.