You use stainless steel because it is strong and dependable. When you pick 321 stainless steel, you get three main benefits. This stainless steel works well in high heat. It resists rust and damage. It is also easier to weld and shape. Titanium in this stainless steel stops carbide from forming. This keeps the steel strong and steady. You find this stainless steel in places where other types might not work. Its makeup helps it do better in hard conditions. The mix of parts in this stainless steel changes how it acts with stress, heat, and chemicals. Each feature comes from the careful mix of ingredients in the stainless steel.

Key Takeaways

- 321 stainless steel works well in hot places. It can handle heat up to 1500°F (816°C) and stays strong.

- This stainless steel does not rust easily. It is good for places with chemicals or lots of water.

- Titanium in this stainless steel stops bad carbides from forming. This keeps it strong and stable.

- Welding this stainless steel is easy. It does not get weak or rusty after welding.

- 321 stainless steel is simple to shape and build with. It fits many jobs in factories.

- Using this stainless steel saves money over time. It lasts long and needs fewer fixes or new parts.

- People use this steel in planes, cars, and chemical plants. It works well in hard and rough places.

- Pick this stainless steel for jobs needing heat and rust protection.

Table of Contents

321 Stainless Steel Properties

When you pick 321 stainless steel, you get special features. These features help it work well in hard places. The way it is made, with titanium, gives it high strength. It also helps it fight rust and makes it easy to weld and shape.

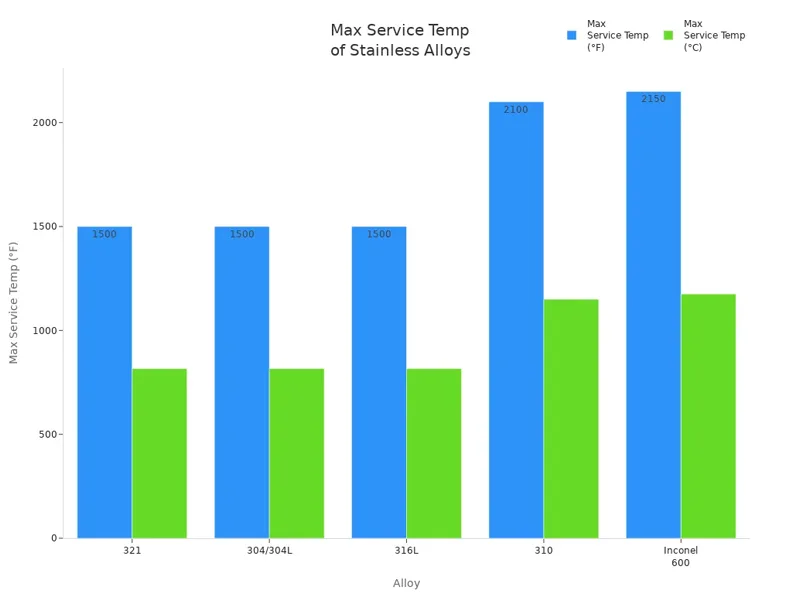

High Temperature Resistance

This stainless steel can handle a lot of heat. You can use it where it gets as hot as 1500°F (816°C). This makes it good for many factories and machines. Titanium helps the steel stay strong and not change shape, even when it is hot for a long time.

| Alloy | Max. Service Temp. (°F) | Max. Service Temp. (°C) |

|---|---|---|

| 321 | 1500 | 816 |

| 304/304L | 1500 | 816 |

| 316L | 1500 | 816 |

| 310 | 2100 | 1150 |

| Inconel 600 | 2150 | 1175 |

Note: Most austenitic stainless steels can work up to 1500°F (816°C). Try not to use them too long between 1100°F and 1400°F. This helps stop bad carbides from forming.

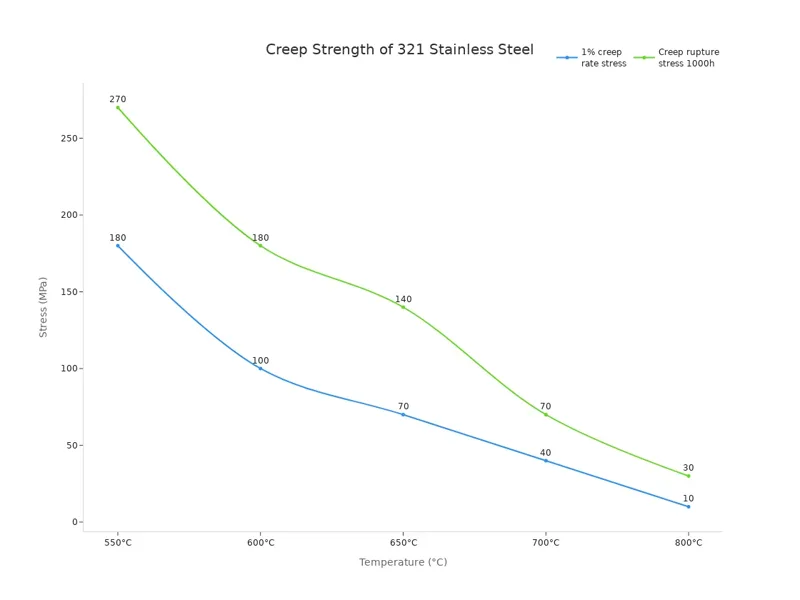

Creep Strength

You want steel that stays strong when it is hot for a long time. 321 stainless steel does this well. It does not change shape much when under heat and pressure. Titanium helps stop carbides from forming, which can make the steel weak.

| Temperature (°C) | Stress to develop 1% creep rate (MPa) | Creep Rupture Stress (MPa) at 1000h |

|---|---|---|

| 550 | 180 | 270 |

| 600 | 100 | 180 |

| 650 | 70 | 140 |

| 700 | 40 | 70 |

| 800 | 10 | 30 |

Structural Stability

You want your steel to keep its shape and strength. This stainless steel does this, even after being hot for a long time. Titanium joins with carbon and stops bad carbides from forming. This makes the high-temperature applications more effective.

Corrosion Resistance

One big feature of this stainless steel is that it fights rust. You can use it where there are chemicals or water that cause rust. Titanium helps it fight rust, even after it is heated or welded.

Oxidation Protection

You need steel that does not break down in air and heat. This stainless steel is better at this than 304 stainless steel. Titanium helps make a strong layer on the outside. You can use it above 1,472°F, where other steels might not work.

Intergranular Corrosion

Welding or heating steel can cause intergranular corrosion. This happens when carbides form and make the steel weak. This stainless steel uses titanium to stop this. It keeps the steel strong, even after welding or heating.

| Temperature (°C) | Corrosion Rate (μm/y) |

|---|---|

| 500 | 60.77 |

| 600 | 136.70 |

| 700 | 301.02 |

Tip: 321 stainless steel fights rust better than many other types, even after welding or heating. You can use it where there are acids or lots of salt.

Weldability and Formability

You may need to weld or shape steel for your work. 321 stainless steel is good for this. Titanium helps stop sensitization, which can cause rust after welding.

Reduced Sensitization

When you weld steel, you do not want sensitization. This is when carbides form and make the steel rust. This stainless steel uses titanium to join with carbon. This stops carbides from forming and keeps welds strong.

Fabrication Ease

321 stainless steel is easy to cut, bend, and weld. It keeps its strength and does not rust easily. Here are some tips for welding this stainless steel:

- Pick the right filler metal to keep it strong and rust-free.

- Heat the steel to 250-400°F before welding to stop cracks.

- Go slow and keep the heat steady while welding.

Note: Because it is easy to weld and shape, you can use 321 stainless steel in many ways. It works well for both simple and hard projects.

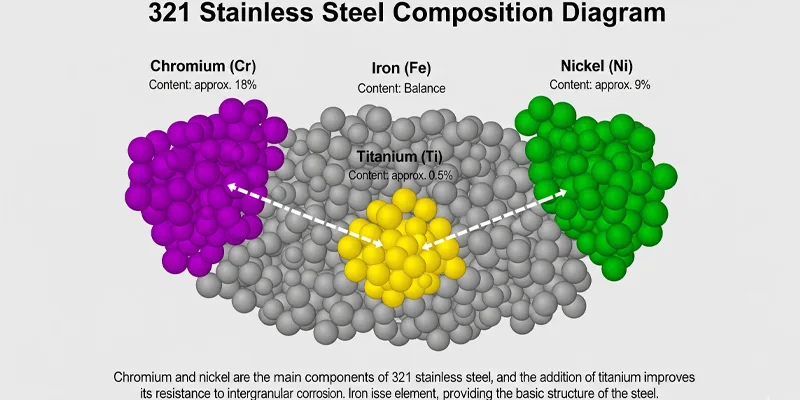

321 Stainless Steel Composition

When you check what is inside 321 stainless steel, you see why it works well in hard places. The mix of parts gives this stainless steel its special strength, ability to fight rust, and handle heat. You need to know what is inside to see how each part helps the steel work.

Chromium and Nickel Content

Chromium and nickel are the main parts in 321 stainless steel. These two parts work together to give you rust protection and strength. Here is a simple table that shows the usual amounts for these parts:

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Cr | 17.0 | 19.0 |

| Ni | 9.0 | 12.0 |

Chromium makes a thin, clear layer on the steel’s surface. This layer keeps the steel safe from rust and harm. You get better rust protection because there is a lot of chromium. Nickel makes the steel tough and helps it stay strong when it gets hot. The mix of parts in 321 stainless steel gives you both strength and protection from strong chemicals.

Note: 321 stainless steel has a bit more chromium than some other types. This means you get better safety in many places.

Titanium Stabilization

Titanium has a special job in 321 stainless steel. When you weld or heat the steel, titanium joins with carbon. This stops bad chromium carbides from forming. If these carbides form, the steel can rust along the lines inside. Titanium is better at joining with carbon than chromium, so it quickly grabs carbon and keeps the steel safe.

Titanium stabilization helps keep the mix of parts steady when you weld or heat the steel. This means you can use this stainless steel where other types might not work. The titanium in the mix helps the steel last longer, even in places with lots of rust or chemicals.

Tip: Titanium stabilization is very important for making the steel last a long time. It keeps the steel strong and safe from rust, even after welding.

Carbon Control

You need to watch the carbon in 321 stainless steel. Too much carbon can cause trouble. The most carbon allowed is 0.08%. Here is a quick table:

| Property | Value |

|---|---|

| Carbon | 0.08% |

Keeping carbon low helps stop rust along the lines inside the steel. High carbon can make bad chromium carbides, which weakens the steel and makes it rust more. By keeping carbon low, you make sure the steel stays strong and fights rust, even when it gets hot.

Remember: The careful mix of chromium, nickel, titanium, and carbon in this stainless steel gives you a material that works well in many tough places.

Corrosion Resistance

If you pick 321 stainless steel, it protects well from rust. This steel keeps its strength and shiny look after high heat. You can use it where other steels might not work. Titanium and other parts help it fight corrosion.

Oxidation Resistance

You want steel that lasts in hot places. 321 stainless steel has strong oxidation resistance. It makes a hard layer that stops oxygen from hurting the metal. When heated to 900°C, a Cr2O3 scale forms. This scale stays on and does not fall off. Your steel stays safe and strong.

At 900°C, 321 stainless steel gets a Cr2O3 scale. This scale is stable and does not peel off. It shows the steel’s great oxidation resistance.

You can use 321 stainless steel where 316 might not work. 316 stainless steel works up to 870°C. 321 stainless steel can go up to 900°C. Titanium helps this stainless steel keep its resistance at high heat. This makes it good for furnaces and exhausts.

- This stainless steel resists oxidation better at 900°C than 316.

- Titanium lets this stainless steel handle more heat.

- The tough layer keeps this stainless steel safe from rust.

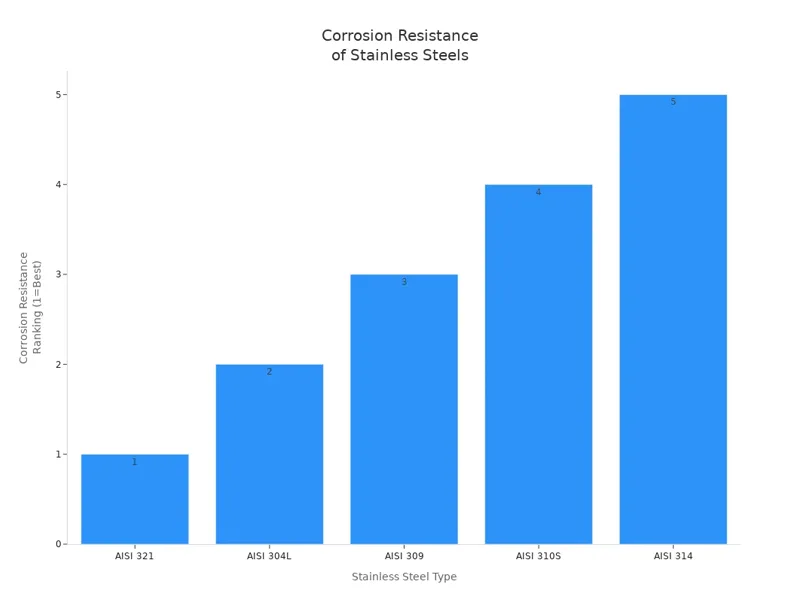

Intergranular Corrosion Prevention

You may worry about rust after welding or heating. 321 stainless steel helps with this problem. Titanium joins with carbon in the steel. This stops chromium carbides from forming. Chromium carbides can make weak spots and rust. Titanium keeps the steel strong and safe.

321 stainless steel is made to resist intergranular corrosion. It stays tough and non-magnetic after high heat. You can weld or heat it without losing strength or shine.

Here is how 321 stainless steel compares to others after heating and cooling:

| Stainless Steel Type | Corrosion Resistance Ranking |

|---|---|

| AISI 321 | 1 |

| AISI 304L | 2 |

| AISI 309 | 3 |

| AISI 310S | 4 |

| AISI 314 | 5 |

You see 321 stainless steel ranks best for corrosion resistance. 304L has less carbon but does not do as well as 321. Titanium gives 321 stainless steel a big boost.

- This stainless steel fights intergranular corrosion better than 304L.

- Titanium helps this stainless steel work well at high heat.

- 304L may not protect as well after heating and cooling.

You can trust 321 stainless steel. It keeps its resistance and fights rust after welding or heat. This makes it a great choice for hard jobs.

Typical Applications of 321 Stainless Steel

You see 321 stainless steel used in many industries. It works well in tough places. This steel is strong and does not rust easily. It can handle very hot temperatures. You find it in jobs where other steels might not work.

| Industry | Primary Applications |

|---|---|

| Aerospace | Exhaust systems, jet engine parts, hydraulic lines |

| Petrochemical | Heat exchangers, pressure vessels, storage tanks |

| Automotive | Exhaust systems, mufflers |

| Food Processing | Equipment for high temperatures and corrosive environments |

| Medical | Surgical instruments and implants |

Industrial Uses

Aerospace

321 stainless steel is used in airplanes and jets. It is found in exhausts, engine parts, and hydraulic lines. These parts get very hot and need to stay strong. 321 stainless steel does not break down up to 1500°F. This is good for engines and exhausts. Other steels, like 316, cannot handle this much heat. 321 stainless steel also fights rust between grains. This makes it great for hot jobs in aerospace.

Note: this stainless steel gives strong heat and rust protection for important airplane parts.

Chemical Processing

Chemical plants use this stainless steel for hard jobs. It can be welded and shaped easily. You can make many things with it. It works well with chemicals, so it is good for tanks and pipes. You want your equipment to last a long time. This stainless steel does not crack from stress. It keeps working in tough places. That is why chemical plants pick it.

- This stainless steel stands up to heat and chemicals.

- You can weld and shape it for many uses.

- It lasts longer, so you do not need to replace it often.

Automotive

Cars use 321 stainless steel in exhausts and mufflers. These parts get hot every day. This stainless steel works better than 304 here. Titanium stops bad carbides from forming. This keeps the steel strong and stops rust. Your exhaust lasts longer and does not break as easily. You get better strength and less damage from heat.

Tip: Pick 321 stainless steel for car exhausts if you want them to last longer than 304 stainless steel.

High Temperature Environments

You need steel that works in very hot places. 321 stainless steel is made for heat between 800-1500°F. You see it in airplanes, factories, and chemical plants. It stays strong and does not rust, even after a long time in heat. You can trust it in furnaces and heat exchangers.

- This stainless steel is best for hot places.

- It works well where heat and rust are problems.

- You get good performance and long life with this steel.

Comparison with Other Stainless Steels

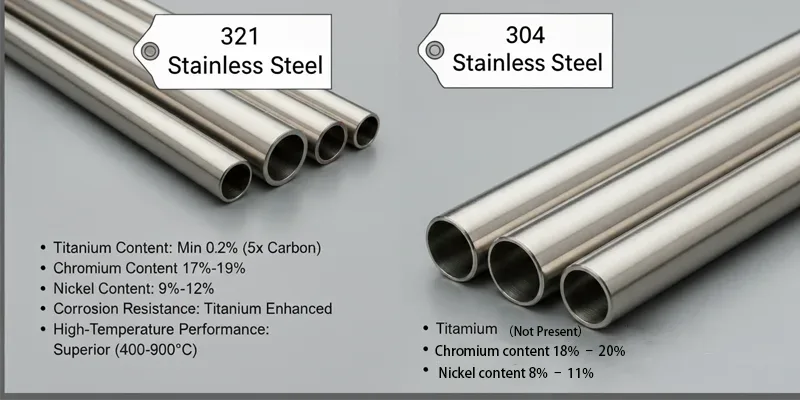

321 vs 304 Stainless Steel

You might want to know how 321 stainless steel is different from 304 stainless steel. Both are austenitic, but they are not the same. 321 stainless steel has titanium in it. This makes a big difference, especially when things get hot. Titanium helps 321 stainless steel work better at high temperatures.

Here is a table that shows how they are different:

| Property | 304 Stainless Steel | 321 Stainless Steel |

|---|---|---|

| Titanium Content | Not present | Minimum 0.2% (5x carbon) |

| Chromium Content | 18% – 20% | 17% – 19% |

| Nickel Content | 8% – 11% | 9% – 12% |

| Corrosion Resistance | Good, but less than 321 | Enhanced due to titanium |

| High-Temperature Performance | Moderate | Better due to titanium |

321 stainless steel works better in heat. Titanium in 321 stainless steel stops bad carbides from forming. This means it stays strong for longer when it is hot. 304 stainless steel is good for many uses, but it does not do as well in heat.

Think about what you need before you pick one:

- Use 321 stainless steel if you need it for 400°C to 900°C.

- Pick 321 stainless steel for better strength in heat.

- Choose 304 stainless steel if you want to save money.

- 321 stainless steel is best for welding and hot jobs because it does not get weak.

Tip: If your project gets very hot or needs strong welds, 321 stainless steel will last longer and protect better.

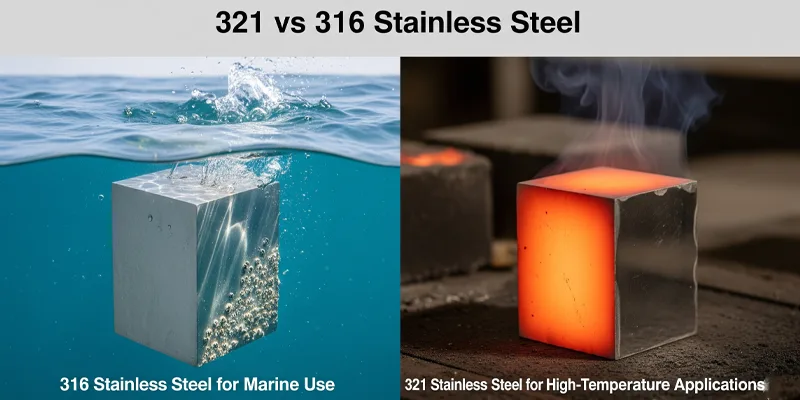

321 vs 316 Stainless Steel

You might also want to compare 321 stainless steel with 316 stainless steel. Both types fight rust, but they are good for different jobs. 316 stainless steel has molybdenum. This helps it fight rust from saltwater and chemicals. That is why 316 stainless steel is best for boats or places with lots of salt.

321 stainless steel does not have molybdenum. It fights rust and stays strong in heat, but it does not work as well as 316 stainless steel in salty or chemical places. If you work near the sea or use chemicals, 316 stainless steel will last longer.

316 stainless steel costs more than 321 stainless steel. This is because it has more molybdenum and nickel.

Here are some things to help you choose:

- Pick 316 stainless steel for jobs with salt or chemicals.

- Use 321 stainless steel for hot jobs where salt is not a problem.

- 316 stainless steel costs more, but it protects better in tough places.

- 321 stainless steel is cheaper if you do not need extra rust protection.

Note: Always pick the stainless steel that fits your job. The right choice will work better and save you money.

When you pick 321 stainless steel, you get three big benefits. This stainless steel fights rust well. It can handle high heat. You can use it in many jobs. The table below shows why people like this stainless steel for hard work:

| Advantage | Description |

|---|---|

| Corrosion Resistance | Great at stopping rust, even in tough places. Works well against crevice, intergranular, and pitting corrosion. |

| Heat Resistance | Works up to 900°C. It does not break down in heat and stays strong. |

| Industrial Applications | Used in planes, cars, chemical plants, food factories, hospitals, and oil plants. |

Titanium in this stainless steel is very important. You pay more at first, but you save money later. This is because it lasts longer and needs fewer repairs.

- Titanium makes stainless steel cost more.

- It helps your stainless steel last longer and need less fixing.

- Cheaper stainless steel may break more in hard places.

You should always check what is in your stainless steel. Picking the right mix helps you get better results and saves money over time.

FAQ

You get 321 stainless steel with titanium added. This titanium helps the steel stay strong when you heat it. You can use this stainless steel in places where other types might fail.

You can weld 321 stainless steel without much trouble. The titanium in this stainless steel stops weak spots from forming. You get strong welds that last longer.

You should use 321 stainless steel in hot places. This stainless steel works well in exhausts, engines, and chemical plants. You get good results when you need both heat and rust protection.

You get strong rust protection with 321 stainless steel. The chromium and titanium in this stainless steel form a shield. This shield keeps the steel safe from water and chemicals.

You can use 321 stainless steel for food equipment. This stainless steel does not react with food. You get a safe and clean surface that lasts a long time.

You should clean 321 stainless steel with mild soap and water. This stainless steel does not need special cleaners. You keep the steel shiny and free from stains.

You can bend and shape 321 stainless steel with normal tools. This stainless steel stays strong after forming. You get parts that hold up under stress.

You may pay more for 321 stainless steel than for some other types. The titanium in this stainless steel adds value. You save money over time because the steel lasts longer.