Choosing the right material is crucial, and understanding the differences between 1018 vs 4140 steel can help you make the best choice for your project. The key distinction lies in their chemical composition and mechanical properties. 4140 steel contains higher amounts of carbon, chromium, and molybdenum, which gives it greater strength and hardness compared to 1018 steel. Below is a comparison highlighting the differences between 1018 vs 4140 steel in important aspects:

| Property / Element | Annealed 4140 Steel | SAE-AISI 1018 Steel |

|---|---|---|

| Carbon Content (%) | 0.38 to 0.43 | 0.15 to 0.20 |

| Ultimate Tensile Strength (MPa) | 740 | 430 to 480 |

| Yield Strength (MPa) | 660 | 240 to 400 |

| Brinell Hardness | 200 | 130 to 140 |

When deciding between 1018 vs 4140 steel, engineers often select 4140 steel for components that require high strength and durability under stress. On the other hand, 1018 steel is preferred for general machining tasks and applications where cost efficiency is a priority.

Table of Contents

Key Takeaways

- 4140 steel is stronger and harder than 1018 steel. This is because it has more carbon and other elements. 1018 steel is easier to cut, weld, and shape. It is good for simple shapes and light parts.

- 4140 steel needs special steps when welding. You must heat it before and after welding to stop cracks. Treatments like heating and coating make steel work better. 4140 steel gets even better with these treatments. 1018 steel costs less money. It is good for projects that need easy shaping and medium strength.

- 4140 steel fights wear, heat, and rust better. It works well for heavy jobs and high stress. Use 1018 steel for things like shafts, gears, and brackets. Use 4140 steel for gears, axles, and machine tools. Picking the right steel saves money and time. It also helps your project work better.

1018 Steel

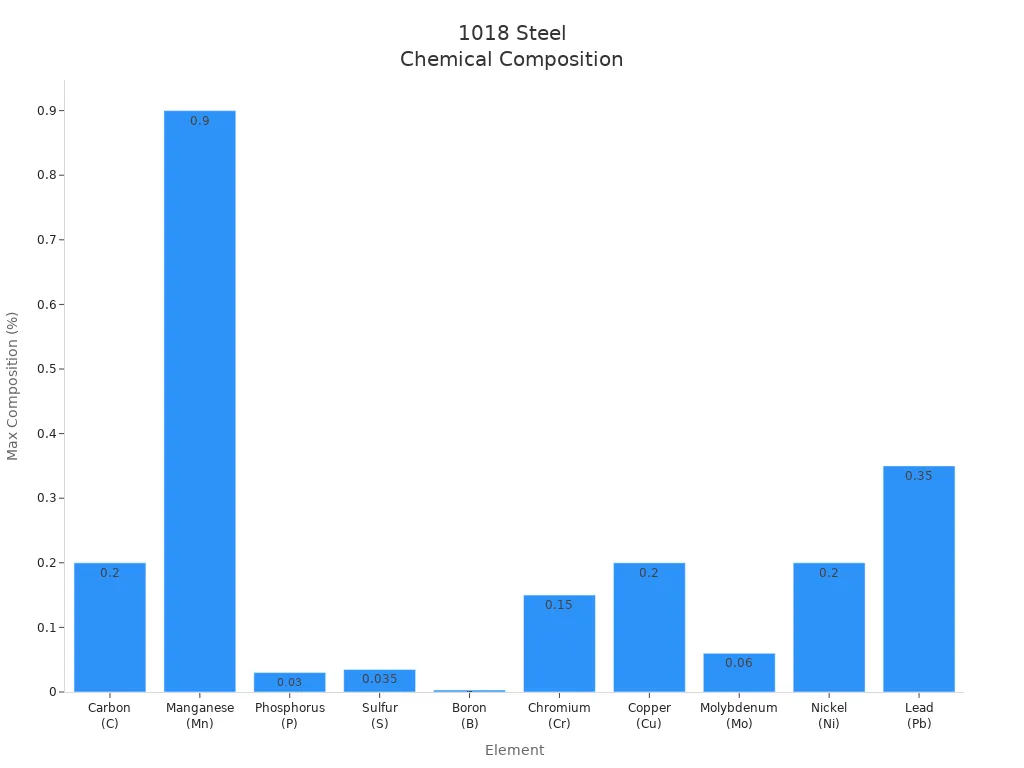

Chemical Composition

1018 steel is a type of low-carbon steel. It has a mix of elements that help it work well. Iron is the main part of 1018 steel. There are also small amounts of other elements. These extra elements change how the steel acts. The table below shows what is in 1018 steel:

| Element | Typical Composition Range (%) | Notes |

|---|---|---|

| Carbon (C) | 0.15 – 0.20 | |

| Manganese (Mn) | 0.60 – 0.90 | |

| Phosphorus (P) | Up to 0.03 | Maximum limit |

| Sulfur (S) | Up to 0.035 | Maximum limit |

| Boron (B) | 0.0005 – 0.003 | |

| Chromium (Cr) | Up to 0.15 | Maximum limit |

| Copper (Cu) | Up to 0.20 | Maximum limit |

| Molybdenum (Mo) | Up to 0.06 | Maximum limit |

| Nickel (Ni) | Up to 0.20 | Maximum limit |

| Lead (Pb) | 0.15 – 0.35 | |

| Iron (Fe) | Balance | Main component |

1018 steel has low carbon. This makes it easy to bend and weld. Manganese helps make it stronger and harder. Other elements like phosphorus and sulfur are kept low. This helps the steel stay tough and not break easily.

Mechanical Properties

1018 steel is strong and can bend without breaking. This makes it useful for many things. How the steel is made can change its strength a little. For example, hot-rolled and cold-drawn steel are a bit different. The table below shows the usual properties:

| Property | Value (Metric) | Approximate Value (Imperial) |

|---|---|---|

| Tensile Strength | 440 – 540 MPa | ~64,000 – 78,000 psi |

| Yield Strength | 370 MPa | ~54,000 psi |

| Elongation | 15 – 20 % | 15 – 20 % |

Cold-drawn 1018 steel can be even stronger. A 3/8″ bar can have very high strength. It can have a tensile strength of over 88,000 psi. Its yield strength can be over 77,000 psi. Elongation shows how much the steel can stretch before it breaks. This number is usually between 12% and 26%. These facts show 1018 steel is strong and can bend a lot.

Note: 1018 steel is good for parts that need to bend. It does not break easily because it is strong and flexible.

Machinability

Machinability means how easy it is to cut or shape a material. 1018 steel is very easy to machine. It has a machinability rating of about 78%. The standard steel B1112 is rated at 100%. This means 1018 steel is easier to cut than many other steels. Steels with more carbon are harder to machine.

| Steel Type | Carbon Content | Machinability Rating | Practical Implication |

|---|---|---|---|

| 1018 Steel | Low Carbon | Excellent (approx. 78%) | Easier to machine and more tool-friendly, preferred for machining-intensive applications |

| 1045 Steel | Medium Carbon | Good | Higher strength but less machinable, requires more tool care during machining |

People pick 1018 steel when they need to do a lot of cutting or shaping. Its low carbon helps tools last longer. It also gives smooth finishes. Using the right tools and coolants helps get the best results. Cutting speeds between 80 and 120 feet per minute work well.

Tip: 1018 steel is great for making parts like shafts, pins, and rods. It is good for jobs that need smooth and exact shapes.

Weldability

1018 steel is very easy to weld. It’s low carbon, means you do not need special steps. Most welding methods work well with it. People use gas welding, resistance welding, MIG, TIG, stick welding, and FCAW. You do not have to heat it before or after welding. This makes 1018 steel a top pick for many jobs.

The table below gives key facts about welding 1018 steel:

| Aspect | Details for 1018 Steel Welding |

|---|---|

| Recommended Welding Processes | MIG, TIG, Stick, FCAW |

| Filler Materials | ER70S-6, ER80S-D2 (MIG/TIG), E7018 (Stick) |

| Shielding Gas | 75% Argon / 25% CO₂ (for MIG) |

| Preheat/Postheat | Not required under normal conditions |

| Welding Technique Tips | Use stringer beads, avoid cold environments, ensure slow cooling |

| Common Challenges | Hard microstructures in heat-affected zone, risk of cold cracking |

| Advantages | Excellent ductility, minimal cracking risk, good toughness |

| Common Applications | Shafts, gears, bolts, axles, frames, furniture |

Welders should keep the area clean and control how fast it cools. Using straight lines instead of weaving helps stop problems. 1018 steel stays tough after welding. It works well for things like shafts, gears, and frames.

Surface Treatment

Surface treatments help 1018 steel last longer and look better. Many companies use these to stop rust and damage. Here are some common ways:

- Black oxide gives some rust protection and a smooth finish.

- Galvanizing adds zinc for strong rust protection.

- Painting or powder coating keeps out water and chemicals.

- Phosphating helps stop rust and makes paint stick better.

- Anodizing forms a hard layer for more strength.

- Nitriding makes the surface harder and stronger.

- Passivation cleans the steel and adds a safe layer.

Nitriding makes the surface very hard and tough. Galvanizing and painting are best for stopping rust. Phosphating is used before painting, and passivation gives even more rust protection.

Tip: Pick the right surface treatment based on where and how you will use the steel.

Heat Treatment

Heat treatment changes how 1018 steel acts for different uses. People use it to make the steel harder, tougher, or more resistant to wear.

- Hardening heats the steel to about 880°C, then cools it fast. This makes it harder but can also make it break more easily.

- Tempering comes after hardening. The steel is heated again at a lower temperature and cooled slowly. This makes it less likely to break and tougher.

- Case hardening, like carburizing or nitriding, makes only the outside hard. The inside stays soft and bendy. This gives a hard shell and a tough center.

Heat treatment can make the steel harder and better against wear, mostly on the outside. Tempering helps keep a good mix of hard and flexible. Case-hardened 1018 steel is used for gears, camshafts, and bearings. These parts need a hard outside and a tough inside.

Steel that is not heat-treated still works well for many easy jobs. This is because it is easy to shape and has good strength. Heat treatment is only needed if you want it to be harder or last longer.

Hardness

The hardness of 1018 steel depends on how people process it. Different treatments change how hard the steel becomes. The table below shows the typical hardness values for 1018 steel after common processing methods:

| Condition | Typical Hardness (Brinell) |

|---|---|

| Annealed | ~127 |

| Hot Rolled | ~143 |

| Normalized | ~135 |

These numbers mean that 1018 steel usually has a Brinell hardness between 127 and 143. If someone uses case hardening, the surface can become much harder. Most parts made from this steel stay in the normal range unless they need extra wear resistance. People often choose this material when they want a balance between hardness and the ability to bend or shape the steel.

Corrosion Resistance

1018 steel does not resist rust as well as some other types of steel. In wet or salty places, it can start to corrode quickly. When exposed to aggressive environments, such as salty water, this steel shows low corrosion resistance. Some treatments can help. For example, a special plasma treatment in humid air can create a thin film on the surface. This film helps protect the steel by making it harder for rust to form. Rotating the steel during this treatment makes the protective layer even better.

However, untreated 1018 steel still rusts more easily than steel with added chromium. Chromium-containing steels form a strong barrier that keeps out moisture and chemicals. In tests, 1018 steel did not perform as well as these alloyed steels. It is important to use coatings, paints, or other surface treatments if the steel will be in a place where it might get wet or dirty.

Note: Always consider extra protection for 1018 steel if it will face harsh weather or chemicals.

High-Temperature Resistance

1018 steel can handle heat, but only up to a certain point. Its properties start to change when the temperature gets too high. Here are some facts about how this steel behaves at different temperatures:

- Cold-drawn 1018 steel changes slowly between 100°C and 300°C.

- Around 500°C, the steel can get a bit stronger due to a process called dynamic strain ageing.

- The steel keeps its shape well up to 650°C.

- It resists thermal creep up to 600°C.

- When the temperature goes above 600°C, the steel starts to lose its strength and other important properties.

Most people use 1018 steel in places where the temperature stays below 600°C. If the steel needs to work in hotter conditions, another type of steel may be a better choice.

Forming and Bending

1018 steel is easy to bend and shape. It has low carbon, so it is simple to work with. This helps people form and weld it without trouble. Workers can bend, crimp, or swage it, and it will not crack. The steel is tough and bends well, so it can be made into many shapes.

- 1018 steel can be bent at room temperature. You do not need to heat it for stamping or stretching.

- It works well for building things that need bending or shaping.

- Its strength is good for jobs where forming is needed.

- It is popular because it is easy to machine, weld, and is strong.

1018 steel is not as bendy as 1008 steel. This is because it has more carbon. It may need some heat for very hard shapes. But it is stronger, so parts keep their shape after bending. Many companies use this steel for parts that must be bent or shaped.

Tip: 1018 steel is a good pick if you want both strength and easy forming.

Cost

1018 steel is not expensive. In 2025, it costs about $0.50 to $0.54 per kilogram. This price is normal for carbon steels. Most carbon steels cost between $0.42 and $0.55 per kilogram. The price does not change much, so it is a good deal. Many companies use it for big projects because it works well and is not costly.

Applications

1018 steel is used in many jobs because it has balanced traits. The table below shows where it is used and why people pick it:

| Industry/Sector | Common Applications | Key Properties Making 1018 Steel Suitable | Reason for Use |

|---|---|---|---|

| Automotive | Gears | Moderate strength, good machinability | Cost-effective and reliable |

| Manufacturing | Shafts | Good ductility, excellent weldability | Easy fabrication |

| Construction | Structural components | Moderate strength, good formability | Versatile and widely available |

People also use it for fasteners, machine parts, and tools. Its low carbon makes it easy to bend and shape. Manganese makes it stronger. It is easy to weld and machine, so making parts is simple. These features make 1018 steel a top choice for gears, shafts, and building parts in cars, factories, and buildings.

4140 Steel

Chemical Composition

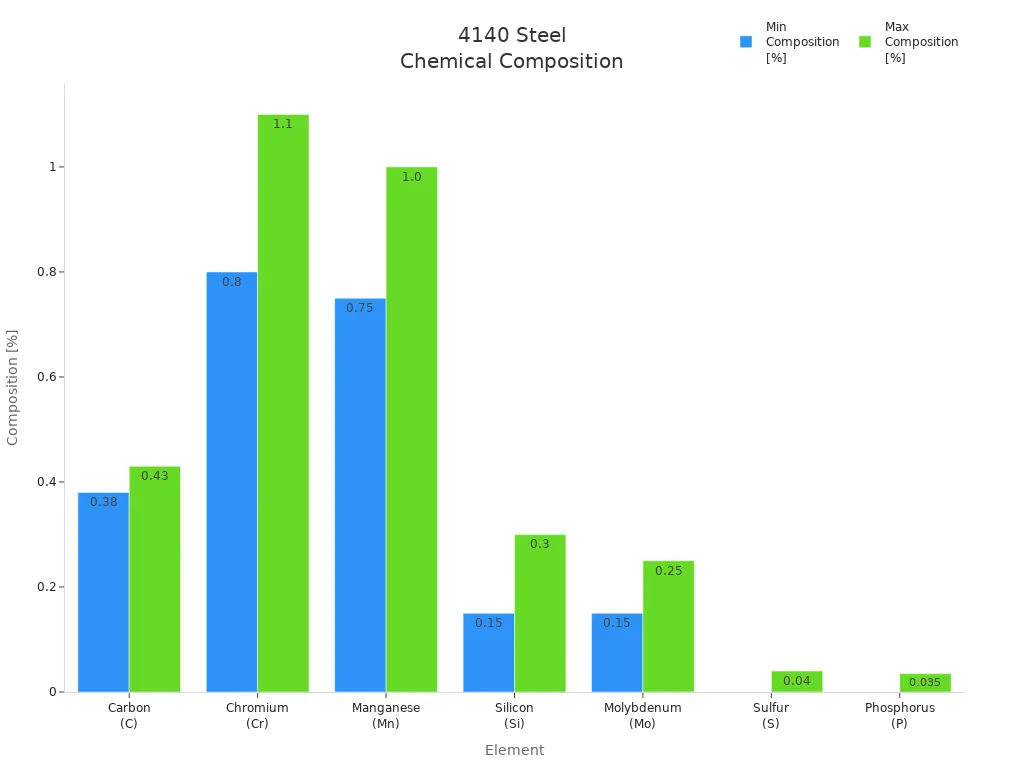

4140 steel belongs to the group of medium-carbon alloy steels. Its chemical makeup gives it special properties that make it stand out. The main elements in 4140 steel include carbon, chromium, manganese, silicon, and molybdenum. These elements work together to improve strength, toughness, and resistance to wear.

| Element | Composition Range [%] |

|---|---|

| Carbon (C) | 0.38 – 0.43 |

| Chromium (Cr) | 0.80 – 1.10 |

| Manganese (Mn) | 0.75 – 1.00 |

| Silicon (Si) | 0.15 – 0.30 |

| Molybdenum (Mo) | 0.15 – 0.25 |

| Sulfur (S) | Up to 0.040 |

| Phosphorus (P) | Up to 0.035 |

| Iron (Fe) | Balance |

Chromium and molybdenum help 4140 alloy steel resist corrosion and wear. Carbon increases hardness and strength. Manganese and silicon add to the toughness. This balanced composition allows 4140 steel to perform well in demanding environments.

Mechanical Properties

4140 steel shows strong mechanical properties. It can handle heavy loads and resist bending or breaking. The steel’s strength comes from its alloying elements and the way it is processed. Both hot-rolled and cold-drawn forms keep high strength and good ductility.

| Condition | Tensile Strength (psi) | Yield Strength (psi) | Elongation (%) |

|---|---|---|---|

| Hot Rolled | 90,000 – 95,000 | 60,200 – 65,000 | 25 – 35 |

| Cold Drawn | 90,000 – 95,000 | 60,200 – 65,000 | 25 – 35 |

Another way to look at these properties is in metric units:

| Property | Value | Unit |

|---|---|---|

| Tensile Strength | 655 | MPa |

| Yield Strength | 415 | MPa |

| Elongation | 25.7 | % |

4140 alloy steel can stretch before breaking, which means it is not brittle. The high tensile and yield strengths make it a good choice for parts that face stress and impact. These properties help 4140 steel last longer in tough jobs.

Machinability

4140 steel offers good machinability, especially in its annealed state. Workers find it easier to cut and shape than some other alloy steels. The steel’s ductility helps with forming and machining. However, it is tougher than 1018 steel, so it needs more force and stronger tools.

Machinists often use 4140 alloy steel for CNC machining. The steel holds its shape well and gives a smooth finish. Compared to 8620 steel, 4140 is a bit harder to machine because of its higher carbon content. Proper heat treatment keeps machinability high and helps avoid cracking.

Tip: Use sharp tools and the right cutting speeds when working with 4140 steel. This helps get the best results and keeps tools from wearing out too fast.

Weldability

Welding 4140 steel takes extra care. This steel has more carbon and alloy parts than regular steel. These parts make it strong but also harder to weld. People use special welding methods to get good welds. You should preheat 4140 steel before welding. The best heat is between 400°F and 600°F. Preheating helps stop cracks from forming.

Use welding types like SMAW, GMAW, and GTAW. Each type needs the right filler metal. E7018, ER70S-6, and ER70S-2 are good choices. Watch the heat while welding. Too much heat can bend or twist the steel. Clamping the steel and using the right order helps keep its shape. After welding, do a post-weld heat treatment. This step makes the welded spot less brittle and relieves stress. Tempering between 1100°F and 1300°F is common. Always use low-hydrogen electrodes and dry filler rods. This stops hydrogen embrittlement and cracking.

Some problems are cracks from cooling too fast, bending, and bad welds. Hydrogen cracks can happen if the area is not dry. Controlling the heat, filler, and cooling helps avoid these issues.

Tip: Always preheat and use post-weld heat treatment for 4140 steel. This keeps the weld strong and safe.

Surface Treatment

Surface treatment helps 4140 steel last longer. Many ways to protect the steel from rust and wear. Some treatments also make the surface harder.

Black oxide coating adds a thin layer that fights rust and looks smooth. Powder coating covers the steel with a tough, colorful layer. This layer stops scratches and keeps out water. Nitriding makes a hard nitride layer on the outside. This layer makes the steel harder and better against rust. Laser surface hardening uses a laser to make the outside very hard. This helps the steel last longer in tough jobs. Case hardening gives a hard shell but keeps the inside tough and bendy.

Other ways, like electropolishing and anodizing, help too. Electropolishing makes the surface smoother and better against rust. Anodizing makes a thick oxide layer that protects better than normal plating. Using both hardening and coatings gives the best results for 4140 steel.

Note: Pick the right surface treatment for how and where you use the steel. For the best life, use both hardening and a coating.

Heat Treatment

Heat treatment changes how 4140 steel acts. This process can make the steel stronger, harder, or more flexible.

Annealing heats the steel to 800°C-872°C and cools it slowly. This makes the steel softer and relieves stress. Normalizing heats the steel to 850°C-900°C and lets it cool in air. This step makes the grain smaller and the steel tougher.

Quenching heats the steel to 815°C-880°C and cools it fast in oil, water, or polymer. This forms martensite, which makes the steel very hard and strong.

Tempering comes after quenching. The steel is heated to 550°C-700°C and then cooled. This step makes the steel less brittle and tougher. Do not temper between 200°C and 420°C to stop embrittlement. Preheating before quenching helps stop stress and cracks.

The quenching liquid changes how hard the steel gets. Polymer quenching can work better than oil or water. The right heat treatment gives 4140 steel the best mix of hard and tough for many jobs.

Tip: Always match the heat treatment to the job. This makes sure 4140 steel works well in tough places.

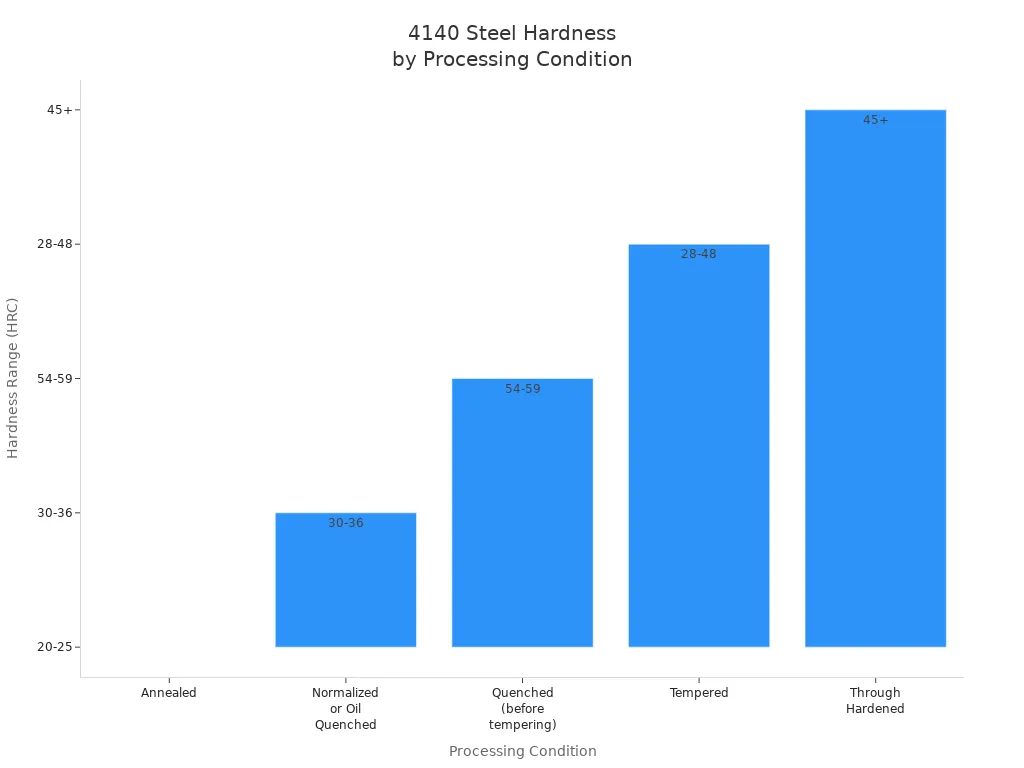

Hardness

4140 steel is known for being very hard. Its hardness changes with how it is treated. When annealed, it is soft, about 20 to 25 HRC. This makes it easy to cut and shape. If it is normalized or oil quenched, the hardness goes up to 30 to 36 HRC. This is good for building strong parts that need to last.

If you quench 4140 steel before tempering, it gets very hard. The hardness can reach 54 to 59 HRC. At this level, the steel is hard but also brittle. Most people temper the steel after quenching. Tempering lowers brittleness and makes it safer to use. Tempered 4140 steel has a hardness between 28 and 48 HRC. The exact number depends on the tempering temperature. Hardening can make it even harder, up to 45+ HRC. This is helpful for grinding and strong machine parts.

| Processing Condition | Typical Hardness Range (HRC) | Notes |

|---|---|---|

| Annealed | ~20-25 HRC | Soft state for easy machining, approx. 197-217 HB |

| Normalized or Oil Quenched | 30-36 HRC | Balanced strength and toughness for structural applications |

| Quenched (before tempering) | 54-59 HRC | Maximum hardness, martensitic microstructure, very brittle |

| Tempered | 28-48 HRC | Adjusted hardness to reduce brittleness; depends on tempering temp |

| Through Hardened | Up to 45+ HRC | Used for grinding, hard turning, and high strength applications |

4140 steel is often quenched in oil to get a martensitic structure. This makes it very hard. Tempering comes next to make it less brittle and more flexible. These steps help 4140 steel work well for many tough jobs.

Corrosion Resistance

4140 steel has chromium and molybdenum in it. These elements help it fight rust better than plain carbon steel. Chromium forms a thin layer on the surface. This layer slows down rust. Molybdenum helps the steel stay tough, even when it gets hot. 4140 steel lasts longer in wet or rough places than regular carbon steel.

Engineers pick 4140 steel for parts that need to resist wear and rust. It does not resist rust as well as stainless steel. But it works well for most factory and machine uses. Special treatments like nitriding can help even more. Nitriding puts a hard nitride layer on the surface. This layer protects the steel and slows down rust. With this treatment, 4140 steel lasts longer, even in harsh places.

Note: For the best rust protection, use surface treatments like nitriding or coatings. These steps help 4140 steel do well where rust is a problem.

High-Temperature Resistance

4140 steel keeps its strength and hardness when it gets hot. It does better than many plain carbon steels. Molybdenum in 4140 steel helps it stay strong at high heat. This makes it a good pick for engine and machine parts.

When heated, 4140 steel does not lose its shape or get weak fast. It stays strong up to about 600°C (1112°F). This means it can handle jobs that would damage softer steels. It is used for gears, shafts, and other parts that face heat and stress.

Tip: If you need steel for hot jobs, 4140 steel is a strong choice. It gives both toughness and heat resistance.

Forming and Bending

Many manufacturers pick 4140 steel for strong parts. This steel does not bend as easily as 4130 steel. It is stronger and harder, so it is not easy to shape. Workers can still form it if they use the right ways. Here are some key facts about bending 4140 steel:

- 4140 steel is harder to bend than 4130 steel because it is stronger.

- Workers can bend it, but they need more force and special tools.

- Heat treatments like annealing make it easier to bend.

- Careful work is needed. Preheating or slow processing helps stop cracks.

- This steel is best for jobs where strength is more important than easy shaping.

Tip: Always use the right tools and heat treatment when shaping 4140 steel. This helps avoid problems.

Cost

The price of 4140 steel is not always the same. It changes by country and market. In 2025, it costs about 10 to 12 Chinese Yuan per kilogram in China. That is about $1.50 to $2.00 in US dollars. In India, it costs 60 to 100 Rupees per kilogram. The price depends on who sells it, how much you buy, and what shape it is in. The cost of iron ore, chromium, and molybdenum also changes the price. Buyers should ask local sellers for the latest price.

Applications

4140 steel is used in many industries because it is strong and tough. The table below shows where it is used and why:

| Industry/Application | Typical Components/Uses | Relevant Properties of 4140 Steel |

|---|---|---|

| Automotive | Shafts, pinions, gears | High strength, good toughness, withstands severe loads |

| Mining | Conveyor rolls, crusher parts, drill bits | High wear resistance, toughness for heavy loads and abrasion |

| Oil and Gas Drilling | Drill collars, drill pipes, stabilizers | High strength, toughness, withstands fluctuating temperatures |

| Aerospace | Landing gear, engine parts, structural elements | Strong, tough, handles high stress and heavy loads |

| Construction Equipment | Excavator teeth, bulldozer blades, crane booms | Wear resistance, toughness for abrasive and heavy load conditions |

| Agricultural Equipment | Plow shares, cultivator teeth, disc blades | Exceptional wear resistance, durability under abrasive conditions |

| Machine Tools | Spindles, feed screws, lead screws | High strength, hardness, resistance to stress |

| Defense | Armor plates, rifle parts | Exceptional strength and toughness for heavy loads |

| Sports Equipment | Hockey sticks, baseball bats, golf clubs | High strength and toughness for high stress applications |

4140 steel has chromium, molybdenum, and manganese in it. These help the steel fight wear, rust, and breaking from use. Its high strength and toughness make it good for cars, planes, building machines, and defense parts. Many companies use it for gears, shafts, tools, and even sports gear. Its mix of strength and toughness helps it work well in hard jobs.

4140 Alloy Steel Features

4140 alloy steel is special because it has many good qualities. Many engineers pick this steel for hard jobs. The list below explains why 4140 steel is used in many industries.

Key Features of 4140 Steel:

- High Strength and Toughness

4140 steel is very strong. It does not bend or break easily. This makes it good for gears and machine parts. - Excellent Hardness

When heated and cooled, 4140 steel gets very hard. People use it for parts that must not wear out fast. - Good Fatigue Resistance

This steel can take stress over and over. It lasts a long time in machines that move a lot. - Wear Resistance

Chromium and molybdenum help 4140 steel fight scratches. Its surface stays smooth after much use. - Moderate Corrosion Resistance

4140 steel does not rust as fast as plain carbon steel. It works better in wet or dirty places, especially with coatings. - Heat Treatable

You can heat and cool 4140 steel to change how hard or strong it is. This helps it fit many different jobs. - Machinability

Workers can cut and shape 4140 steel with the right tools. It gives a nice finish and keeps its size well. - Formability

4140 steel can be bent or formed, mostly after annealing. It is not as easy to shape as softer steels, but it stays strong.

Feature Comparison Table

| Feature | 4140 Steel Benefit | Typical Application Example |

|---|---|---|

| High Strength | Handles heavy loads | Automotive axles |

| Hardness | Resists surface wear | Mining drill bits |

| Fatigue Resistance | Lasts under repeated stress | Machine spindles |

| Corrosion Resistance | Slows rust and oxidation | Oilfield equipment |

| Heat Treatable | Customizes properties | Aerospace landing gear |

| Machinability | Precise shaping possible | Tooling components |

Tip: 4140 steel is best for parts that need to be strong and last a long time. Always pick steel with the right features for your job.

4140 alloy steel is tough, hard, and does not wear out fast. These things make it a top pick for engineers who need strong steel in rough places.

1018 vs 4140 Steel

Composition Comparison

The composition of steel affects how it performs in different situations. 1018 vs 4140 steel shows clear differences in their chemical makeup. 1018 steel contains less carbon and does not have chromium or molybdenum. 4140 steel has higher carbon, chromium, and molybdenum. These elements change the properties of each steel.

| Element | 1018 Steel (%) | 4140 Steel (%) |

|---|---|---|

| Carbon | 0.15 – 0.20 | 0.38 – 0.43 |

| Manganese | 0.60 – 0.90 | 0.75 – 1.00 |

| Chromium | None | 0.80 – 1.10 |

| Molybdenum | None | 0.15 – 0.25 |

| Silicon | Up to 0.30 | 0.15 – 0.30 |

| Phosphorus | Up to 0.04 | Up to 0.035 |

| Sulfur | Up to 0.05 | Up to 0.040 |

1018 steel has a simple composition. It works well for general uses. 4140 steel has a more complex mix. It performs better in tough jobs. Chromium and molybdenum help 4140 steel resist wear and heat. Carbon increases hardness and strength. These differences in composition lead to different mechanical properties.

Tip: Choose 1018 steel for easy machining and forming. Pick 4140 steel for high strength and durability.

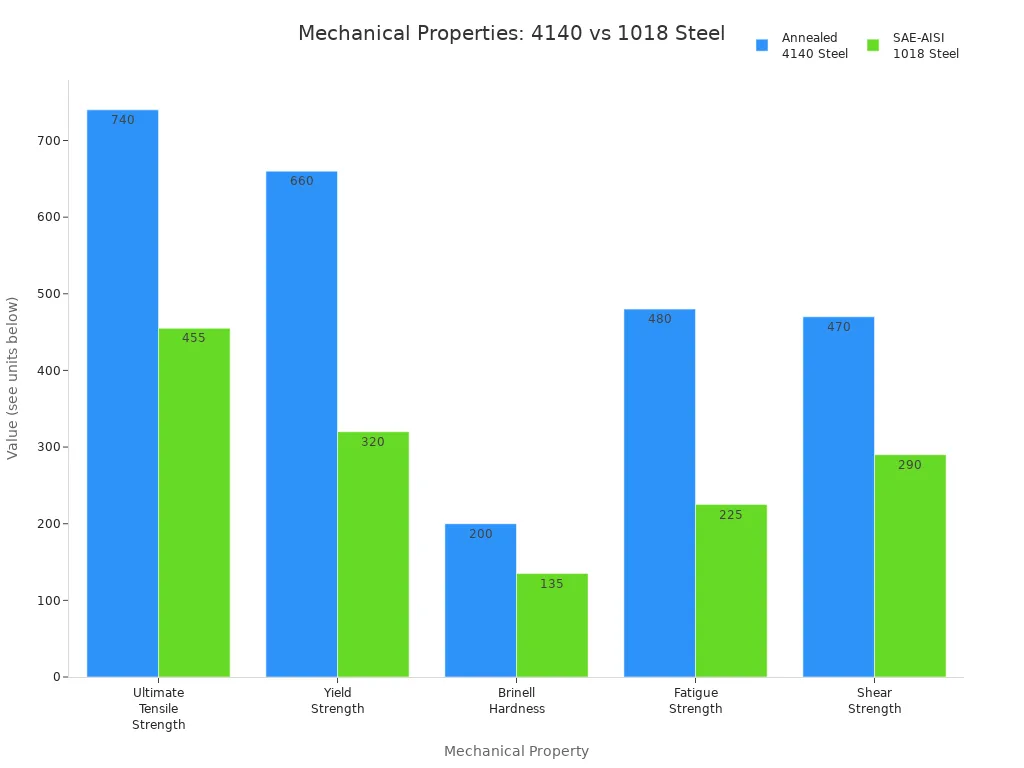

Mechanical Properties Comparison

Mechanical properties show how steel reacts to force, stress, and bending. 1018 vs 4140 steel have different strengths and hardness. 1018 steel offers good ductility and moderate strength. 4140 steel provides higher strength and hardness.

| Property | 1018 Steel | 4140 Steel |

|---|---|---|

| Tensile Strength | 440 – 540 MPa | 655 – 745 MPa |

| Yield Strength | 370 MPa | 415 – 660 MPa |

| Elongation | 15 – 20% | 25 – 35% |

| Brinell Hardness | 127 – 143 | 200 – 300 |

1018 steel bends easily and does not break quickly. It works well for parts that need to flex. 4140 steel resists bending and holds up under heavy loads. It lasts longer in machines and tools. The higher hardness of 4140 steel means it wears out less quickly.

Note: Mechanical properties help decide which steel fits a project. 1018 steel suits light-duty jobs. 4140 steel fits heavy-duty tasks.

Machinability and Weldability

Machinability means how easy it is to cut or shape steel. Weldability shows how well steel joins with other pieces. 1018 vs 4140 steel differs in both areas.

Machinability:

- 1018 steel has excellent machinability. Workers can drill, cut, and mill it with standard tools.

- 4140 steel needs stronger tools and slower speeds. It is tougher to machine because of its higher hardness.

Weldability:

- 1018 steel welds easily. Most welding methods work without special steps.

- 4140 steel requires preheating before welding. Post-weld heat treatment helps prevent cracks. Special filler metals improve weld quality.

| Feature | 1018 Steel | 4140 Steel |

|---|---|---|

| Machinability | High | Moderate |

| Weldability | Excellent | Needs preheat and postheat |

Workers choose 1018 steel for jobs that need lots of machining or welding. 4140 steel fits projects where strength matters more than easy processing.

Tip: For simple machining and welding, 1018 steel is the best choice. For tough jobs, use 4140 steel with proper welding steps.

Surface and Heat Treatment

Surface and heat treatment play a big role in how 1018 vs 4140 steel perform in real-world jobs. These treatments change the outside and inside of the steel to improve its properties.

Surface Treatment:

- 1018 steel often gets surface treatments like painting, galvanizing, or black oxide coating. These methods help protect the steel from rust and make it look better.

- 4140 steel usually needs stronger surface protection. Many engineers use nitriding or case hardening. These treatments make the surface harder and help the steel last longer in tough places.

Heat Treatment:

- 1018 steel does not respond much to heat treatment because it has low carbon. People use normalizing or case hardening to make the surface harder, but the inside stays soft and bendable.

- 4140 steel changes a lot with heat treatment. Quenching and tempering make it much harder and stronger. This steel can be adjusted for different jobs by changing the heat treatment process.

| Treatment Type | 1018 Steel | 4140 Steel |

|---|---|---|

| Surface Treatment | Painting, galvanizing | Nitriding, case hardening |

| Heat Treatment | Normalizing, carburizing | Quenching, tempering |

| Effect on Properties | Surface hardness improves | Both surface and core hardness improve |

Tip: Choose the right surface and heat treatment based on where the steel will be used and what properties are needed.

Hardness and Strength

Hardness and strength decide how well steel can handle force, wear, and bending. These properties help engineers pick the right material for each job.

- 1018 steel has moderate hardness and strength. It bends easily and does not break quickly. This steel works well for parts that need to flex or be shaped.

- 4140 steel is much harder and stronger. It can take heavy loads and resist wear. After heat treatment, its hardness goes up a lot. This makes it a good choice for gears, axles, and machine parts.

| Property | 1018 Steel | 4140 Steel |

|---|---|---|

| Hardness (Brinell) | 127 – 143 | 200 – 300 |

| Tensile Strength | 440 – 540 MPa | 655 – 745 MPa |

| Yield Strength | 370 MPa | 415 – 660 MPa |

Engineers look at these numbers when they need steel for strong or tough jobs. 4140 steel stands out for high strength and hardness, while 1018 steel is better for easy forming and light-duty uses.

Note: Always match the hardness and strength of the steel to the needs of the project.

Corrosion and Temperature Resistance

Corrosion and temperature resistance show how steel performs in harsh environments. These properties affect how long the material lasts and how safe it is.

- 1018 steel does not resist rust well. It needs coatings or paint to protect it in wet or salty places. Without protection, it can corrode quickly.

- 4140 steel resists corrosion better because it has chromium and molybdenum. These elements help slow down rust and make the steel last longer. Surface treatments like nitriding can improve this even more.

When it comes to temperature resistance:

- 1018 steel keeps its properties up to about 600°C. Above this, it starts to lose strength.

- 4140 steel handles high temperatures better. It stays strong and hard up to 600°C and sometimes higher, depending on the heat treatment.

| Property | 1018 Steel | 4140 Steel |

|---|---|---|

| Corrosion Resistance | Low | Moderate |

| Temperature Resistance | Up to 600°C | Up to 600°C or higher |

Tip: For jobs in wet, salty, or hot places, 4140 steel offers better protection and longer life.

Forming and Bending

Forming and bending are important when choosing between 1018 vs 4140 steel. These processes help manufacturers shape steel into different parts. 1018 steel bends easily. Workers can form it at room temperature. They do not need special tools for most jobs. This steel works well for stamping, crimping, and swaging. It keeps its shape after bending. Many companies use it for parts that need to be shaped or welded.

4140 steel is stronger and harder. It does not bend as easily as 1018 steel. Workers need more force and special equipment. Sometimes, they heat the steel before bending. This step helps prevent cracks. 4140 steel is best for jobs where strength matters more than easy forming. It holds up under heavy loads and stress.

The table below shows how these two steels compare in forming and bending:

| Property | 1018 Steel | 4140 Steel |

|---|---|---|

| Ease of Forming | Very easy | Moderate to difficult |

| Bending at Room Temp | Yes | Sometimes, but may need heat |

| Tool Requirements | Standard tools | Heavy-duty tools |

| Risk of Cracking | Low | Moderate |

Cost

Cost also plays a big role in material selection. 1018 steel costs less. Many companies choose it for large projects. The price stays steady, which helps with budgeting. 4140 steel costs more. The higher price comes from its alloy content and extra processing steps. Buyers pay more for its strength and durability.

Tip: Select 1018 steel for projects that need easy forming and lower cost. Choose 4140 steel for parts that must handle heavy loads and stress.

Application Differences

Engineers use 1018 vs 4140 steel for different jobs. Each steel fits certain applications because of its properties. 1018 steel works well for parts that need to be shaped, welded, or machined. Manufacturers use it for shafts, gears, brackets, and fasteners. It fits automotive, construction, and general manufacturing needs.

4140 steel is stronger and tougher. It handles high stress and wear. Companies use it for gears, axles, machine parts, and tools. It fits industries like mining, oil and gas, aerospace, and heavy equipment. This steel lasts longer in harsh environments.

The list below shows common uses for each steel:

- 1018 Steel Applications:

- Shafts

- Pins

- Gears

- Brackets

- Fasteners

- 4140 Steel Applications:

- Gears

- Axles

- Drill collars

- Machine spindles

- Structural parts in aerospace

Note: Always match the steel type to the job requirements. 1018 steel suits light-duty and high-volume parts. 4140 steel fits heavy-duty and high-stress components.

Pros and Cons

1018 Steel Pros

1018 steel gives many benefits to workers and engineers. Here are the main good points:

- Excellent Machinability

Workers can cut, drill, and shape 1018 steel easily. They use regular tools for this steel. Machinists pick it for parts that need exact sizes. - High Weldability

Welders join 1018 steel with common welding methods. Its low carbon means less chance of cracks. Most welding does not need heating before or after. - Good Formability

Makers bend and shape 1018 steel without much trouble. The steel stays strong while being formed. It works for stamping, crimping, and swaging. - Consistent Quality

1018 steel has the same traits in every batch. Engineers trust it for big jobs that need steady results. - Affordable Cost

1018 steel costs less than many other steels. Companies use it for big projects to save money. - Smooth Surface Finish

Parts made from 1018 steel look clean and smooth. This means less need for extra polishing.

Tip: 1018 steel is great for jobs needing easy cutting, welding, and shaping. It helps keep costs down.

1018 Steel Cons

1018 steel has some downsides to think about. Here are the main weak points:

- Lower Strength

This steel cannot hold heavy loads like alloy steels. Engineers do not use it for high-stress parts. - Limited Hardness

1018 steel is softer than many other steels. It wears out faster in rough places. - Poor Corrosion Resistance

The steel rusts fast in wet or salty spots. You need coatings or paint for outdoor use. - Minimal Response to Heat Treatment

Heat treatment does not make the inside much harder. Only the outside gets harder after case hardening. - Not Ideal for High-Temperature Applications

The steel gets weak above 600°C. It is not good for jobs needing heat resistance.

Note: Pick 1018 steel for light jobs. It works best where you do not need lots of strength or hardness.

4140 Steel Pros

4140 steel is strong and works well in tough places. These features make it a top pick:

- High Strength and Toughness

This steel does not bend or break under heavy loads. Engineers use it for gears, axles, and machine parts. - Excellent Hardness

Heat treatment makes 4140 steel much harder. It lasts longer in rough conditions. - Good Wear Resistance

Chromium and molybdenum help stop scratches and damage. It works well in mining and building machines. - Moderate Corrosion Resistance

The alloy parts slow down rust. The steel lasts longer in wet or dirty places. - Effective Heat Treatability

Makers change 4140 steel’s traits by quenching and tempering. The steel fits many different jobs. - Reliable Performance at High Temperatures

The steel keeps its strength and shape up to 600°C. It works well for engine and machine parts that get hot.

Tip: 4140 steel is best for hard jobs. It gives strength, hardness, and long life for tough work.

4140 Steel Cons

4140 steel has many good points, but it also has some problems. Engineers and builders need to know about these before picking this steel. Knowing the downsides helps people choose the right material for their job.

Main Limitations of 4140 Steel:

- Difficult Machinability

4140 steel is harder than many other steels. This makes it tough to cut or drill. Workers need strong tools and must go slowly. Tools wear out faster, so they need to be changed more often. Machinists use carbide or high-speed steel tools for better results. - Special Welding Requirements

Welding 4140 steel is not as easy as with low-carbon steels. Its higher carbon and alloy parts make cracks more likely. Welders must heat the steel before welding and treat it after. These steps take more time and skill. If done wrong, the weld can be weak or crack. - Higher Cost

4140 steel costs more than plain carbon steels like 1018. The price is higher because of its alloy parts and extra steps in making it. Using a lot of 4140 steel can make a project cost more. Planning for the budget is important when picking this steel. - Challenging Forming and Bending

4140 steel is strong and hard, so it is tough to bend or shape. Workers need more force and sometimes must heat it to form it. Regular tools may not work well. Making complex shapes is hard without special machines. - Moderate Corrosion Resistance

4140 steel fights rust better than basic carbon steel, but not as well as stainless steel. In wet or salty places, it still needs coatings or treatments. Without these, the steel can rust over time.

Note: Engineers should always pick steel that fits the job. Using 4140 steel in the wrong way can mean more work or higher costs.

Summary Table: 4140 Steel Cons

| Limitation | Impact on Use |

|---|---|

| Difficult Machinability | Needs strong tools, more tool changes |

| Special Welding Steps | Requires preheat and post-weld treatment |

| Higher Cost | Increases project expenses |

| Hard to Form/Bend | Needs more force or heat |

| Moderate Corrosion Resistance | Needs coatings in harsh environments |

Engineers and builders should think about these points before using 4140 steel. Good planning and the right steps help solve these problems and get the best from this alloy steel.

Choosing the Right Steel

Selection Factors

Picking the right steel depends on a few big things. Engineers think about what the steel must do. They look at how strong it needs to be and what kind of work it will do. They also check how much money they can spend.

- Strength and Hardness:

If a part must hold a heavy weight or not wear out, 4140 steel is better. This steel is stronger and harder than 1018 steel. - Machinability and Weldability:

If you need to cut or weld the steel easily, 1018 steel is best. Workers can shape and join this steel without much trouble. - Forming and Bending:

If the part needs lots of bends or shapes, 1018 steel is easier to bend. - Corrosion and Temperature Resistance:

If the part will get wet or hot, 4140 steel lasts longer. Its special mix helps stop rust and keeps it strong when hot. - Cost:

Money is important. 1018 steel costs less. It is good for big projects or when you need to save money.

The table below shows how these things compare:

| Factor | 1018 Steel | 4140 Steel |

|---|---|---|

| Strength | Moderate | High |

| Machinability | Excellent | Good |

| Weldability | Excellent | Needs care |

| Forming/Bending | Easy | Moderate |

| Corrosion Resistance | Low | Moderate |

| Cost | Lower | Higher |

Tip: Pick the steel that fits your job. This helps you avoid mistakes and saves money.

Application Guidance

People should think about how they will use the steel. For simple parts like machine pieces, brackets, or shafts, 1018 steel works well. It is easy to shape and weld. For gears, axles, or parts that get a lot of stress, 4140 steel is better.

- Use 1018 steel for car parts, furniture frames, and building work.

- Pick 4140 steel for mining tools, oilfield parts, and airplane pieces.

If your project needs something special, like fighting wear or heat, talk to an expert. They can help you pick the best steel and treatment. Bring drawings, load info, and where you will use it. This helps them give you the right advice.

Note: For hard jobs, ask a trusted supplier or materials engineer. They know how to match steel to your needs.

People who plan and ask questions get better results. Picking the right steel saves time, money, and problems.

- 1018 steel is simple to cut, weld, and shape.

- 4140 steel is stronger, harder, and does not wear out as fast.

- Engineers pick steel by looking at what the project needs, how much it costs, and how well it works.

People need to check all the steel’s features before picking one. Asking experts can help you get the best steel for your job.

FAQ

1018 steel contains less carbon and no alloying elements like chromium or molybdenum. 4140 steel has higher carbon, chromium, and molybdenum. This makes 4140 steel stronger and harder than 1018 steel.

Welders find 1018 steel very easy to weld. 4140 steel needs preheating and post-weld heat treatment. This extra care helps prevent cracks and keeps the weld strong.

Machinists prefer 1018 steel for easy cutting and shaping. 4140 steel is harder and needs stronger tools. 1018 steel gives smoother finishes and faster production.

4140 steel resists rust better because it contains chromium and molybdenum. 1018 steel rusts faster, especially in wet or salty places. Both steels benefit from protective coatings.

Manufacturers use 1018 steel for shafts, gears, brackets, and fasteners. It works well in automotive, construction, and general manufacturing because it is easy to shape and weld.

4140 steel keeps its strength and hardness at high temperatures, up to about 600°C. This makes it a good choice for engine parts, gears, and heavy machinery.

1018 steel usually costs less than 4140 steel. Companies often choose 1018 steel for large projects where cost matters most.

Workers can bend 1018 steel easily at room temperature. 4140 steel is harder to bend and may need heat or special tools. 1018 steel is better for parts that need shaping.