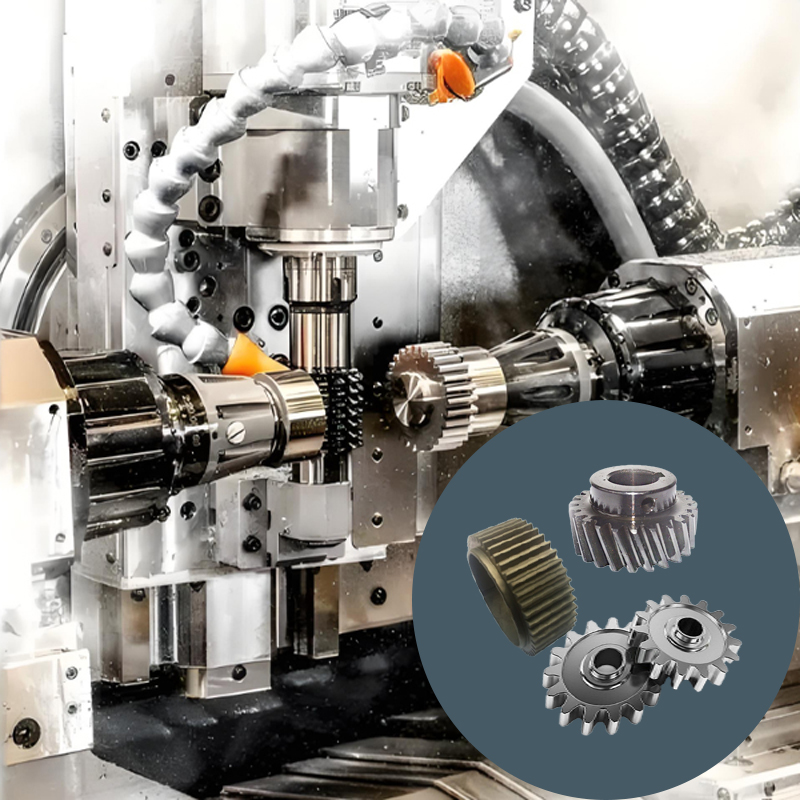

Machining Manufacturer

Our precision machining services are designed to meet your manufacturing needs: Our precision machining services are designed to meet the manufacturing needs of a wide range of industries. With our expertise and experience, we specialize in producing high quality parts that meet your exact specifications.

You need more than just machined parts you need a supplier with 12 years of experience to guarantee the quality and profitability you need. Let AFI Industrial Co., Ltd. help you get the assurance you need.

Save Your Money And Time By Choosing The Exact Process

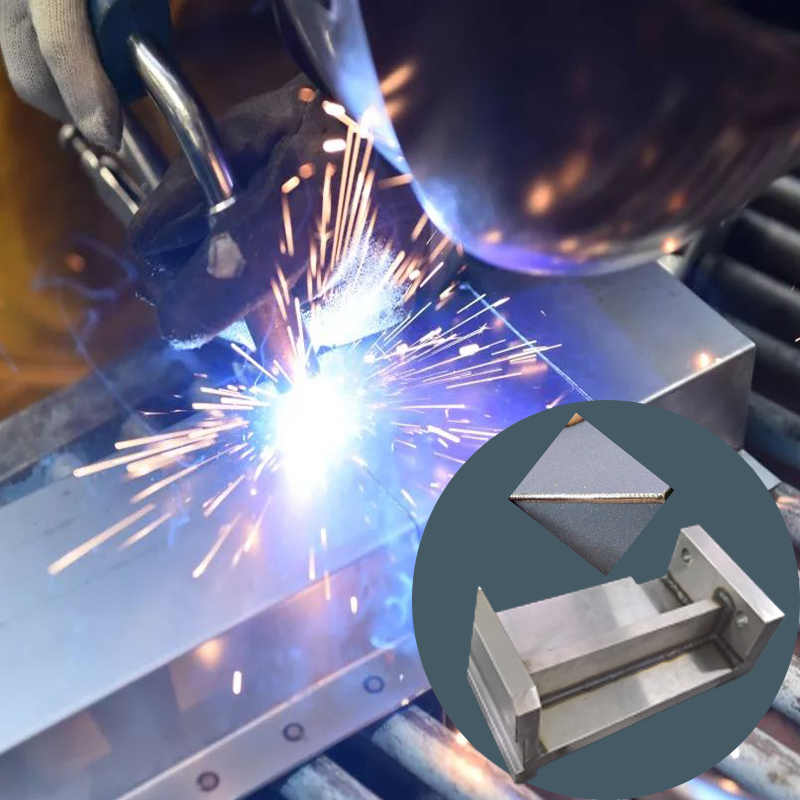

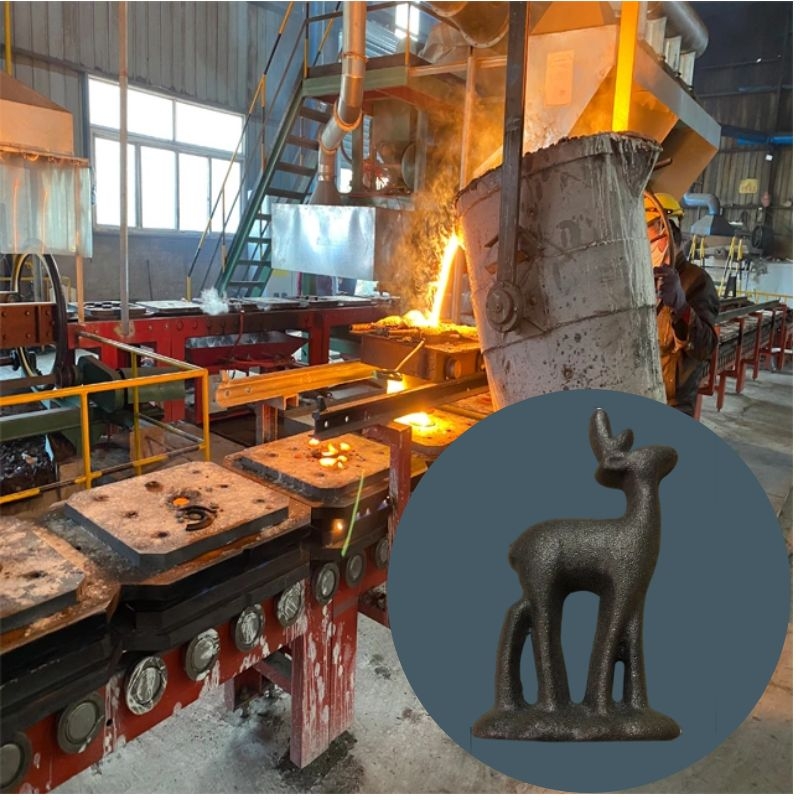

30+ kinds of technical support and more than 10+ surface treatments are enough to meet your product needs

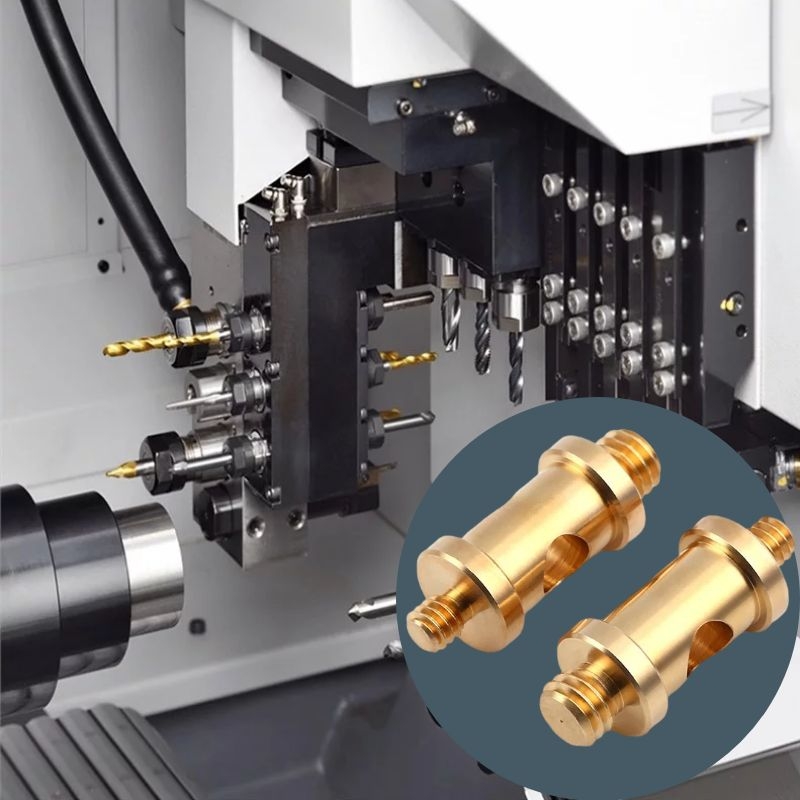

—— We have a variety of equipment, including CNC lathes, CNC milling machines, stamping machines, die-casting machines, etc., to meet the requirements of different production processes for customers.

—— We have experienced engineers and technicians who can apply the best production processes to help customers save costs to the greatest extent.

—— We have a perfect quality control system that guides employees to strictly control product quality at every production link.

—— We can provide customized, exclusive, one-stop solutions for customers to reduce their complicated procurement work.

The Benefits and Value You Get from CNC Machining

- 3-15 days delivery depending on quantity

- Professional design and sales team, accept any type of file

- 20 years of machining expertise,superior production process

- With more than 100 machines to cope with customers’high volume demand

- Adopt high drop packaging test standard

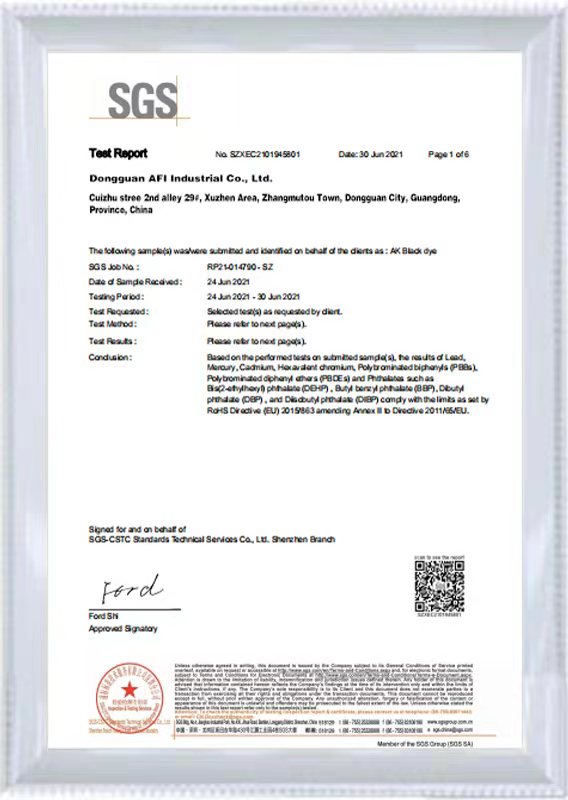

- Qualified by SGS and ISO 9001 certification

- Fast response within 2 hours,fast quotation within 4 hours

- No forcing you to provide large volume requests

- 100% full inspection using CMM before shipment

- Paid production process with no markup

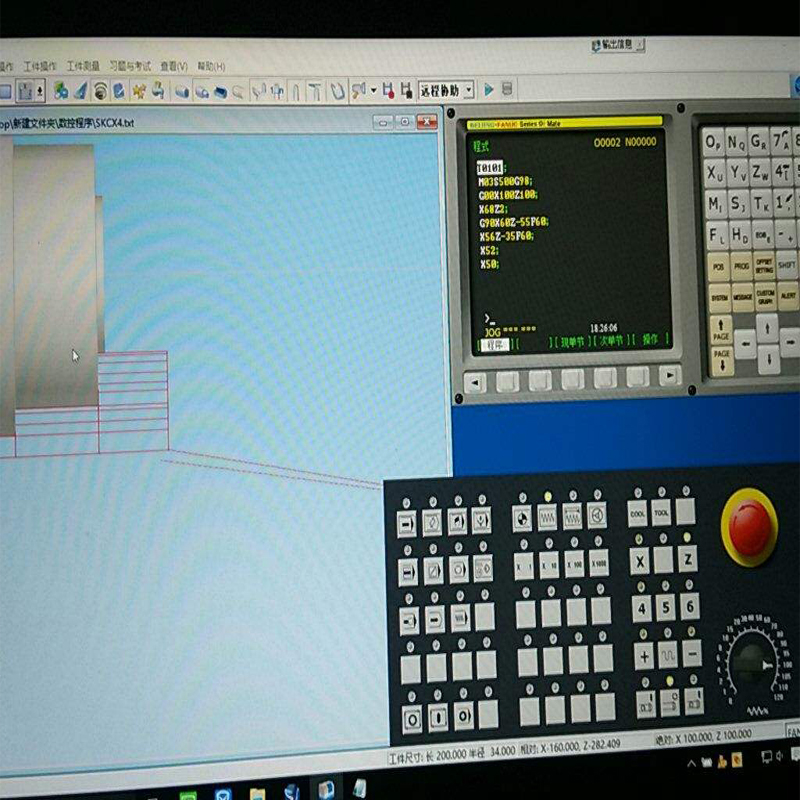

We use CNC turning and milling technology to manufacture customized parts of various shapes for our customers to meet their different needs. CNC machining can process raw materials into complex products at one time, which not only reduces processing technology and saves processing costs, but also ensures product dimensional accuracy and appearance finish. In addition, the computer-controlled processing process can ensure the stable quality of batch products, so that our customers can get better quality products at a more favorable price, effectively improving market competitiveness.

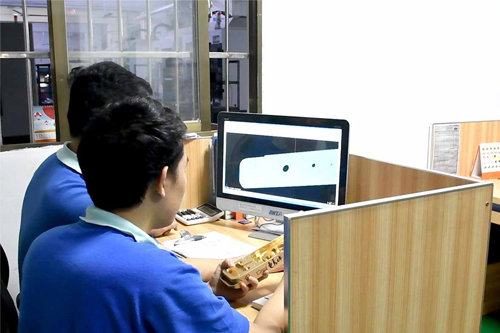

Machining Quality Control

Quality control in CNC machining ensures that parts meet design standards by tracking and inspecting the manufacturing process. This process produces high-quality and precise parts, ensuring the testing and high-frequency measurement of product dimensions, surface finish, and material properties to eliminate defects and guarantee consistency. AFI Industrial Co., Ltd. strictly implements the quality control process to ensure that the metal parts of our customers meet the requirements of the drawings and assembly.

Effective Quality Control Helps You Get Quality Products

Incoming Quality Control

Inspect raw materials to ensure that the materials provided by suppliers all meet the requirements of the drawings and technical specifications, guaranteeing the quality of parts from the source.

Input Process Quality Control

Quality inspection during the manufacturing process ensures that each step is qualified and that the quality is consistent.

Final Quality Control

Systematic and comprehensive quality review to ensure that the customer’s use, assembly, and display meet the requirements.

Outgoing Quality Control

Finally, achieve 100% qualified quality, ensuring no defective products are sent to customers for use.

Machining Certification Guarantee

After obtaining the certificate, enterprises are able to improve product quality by implementing standards and improving and perfecting management, so that each household is satisfied.

Official certification by third parties ensures that products and services are secure and standardized and that every item delivered to the customer is guaranteed.

International standardized certification and recognition ensure that our workflow, product quality, and management level maintain a high degree of worldwide consistency, ensuring the safe use of each customer.

We Provide One-Stop Service For Machining manufacturers

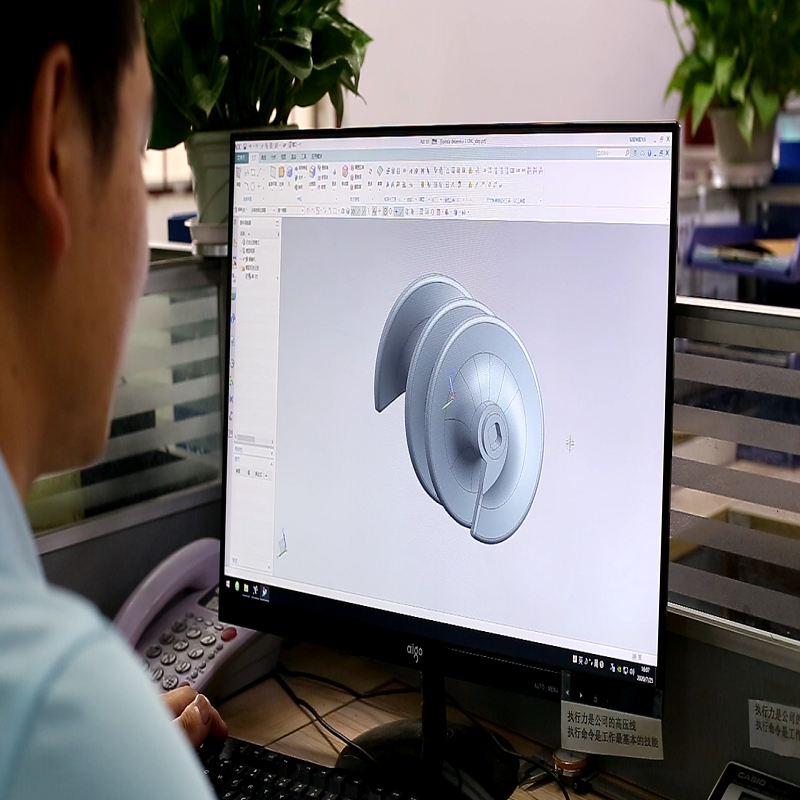

1 => Design

Precise design according to customer requirements

2 => Drawing

Drawing and distribution of the designed products

3 => Programming

Writing human-computer dialogue language

4 => Cutting

Breakdown of standard specification raw materials

5 => Manufacturing

Machines for production processing

6 => Surface Finishing

Surface treatment of finished products

7 => Assembly

Assemble all kinds of qualified parts

8 => Packaging

Complete packaging of completed products

Machining Manufacturing Video

Each part is manufactured using the correct machining process to help customers get the desired product while reducing costs at no extra charge. It is our lifelong mission as a machining manufacturer to provide each customer with efficient, high-quality, and cost-effective machining services.

Official certification by third parties ensures that products and services are secure and standardized and that every item delivered to the customer is guaranteed.

Machining Manufacturing and Shipping Time

1. Design and manufacturing time

We start with a discussion of the design. Put them in the manufacturing process to complete the quality required by the drawings.

2. Packing and boxing all products time

The staff pack the products in cartons. They take a short time because it is an easy task.

3. Custom clearance and loading time

The products are loaded onto trucks through logistics companies, cleared through customs, and then the drivers deliver them to various dispatch points.

4. Sea and land transportation time

Once the products arrive at their destination, you will receive an alert. You can plan how to collect your shipped goods.

Our Attitude And Way of Dealing With Problems

- Team Discussion Questions

- Interim measures

- Analyze the root cause

- Permanent measures

- Preventive measures

- No excuses and no complaints

- Keep the right attitude

- Not using any excuses

- Find solutions quickly

- Improve the recurrence of problems

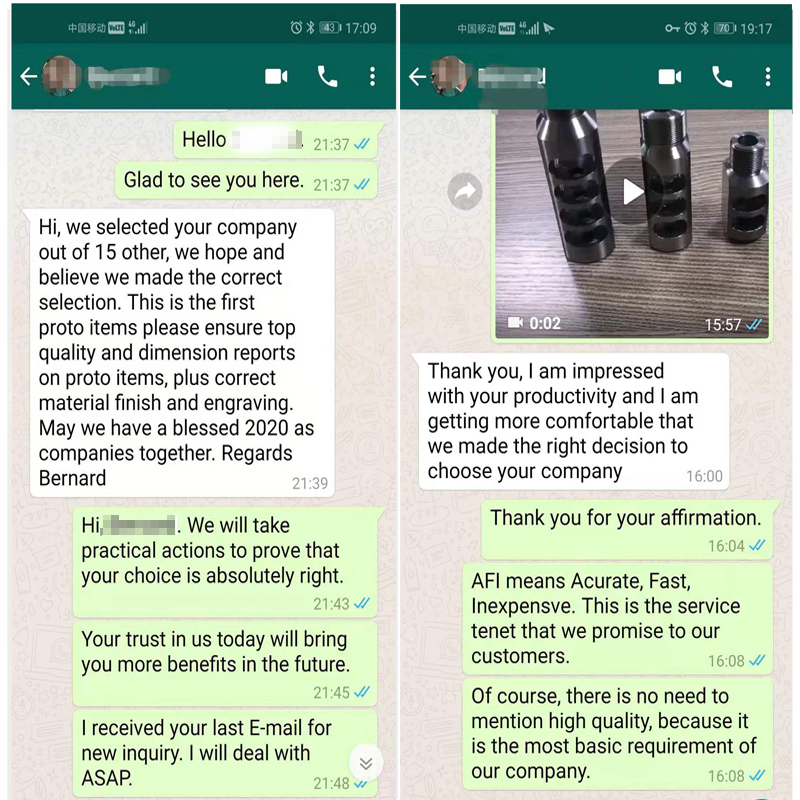

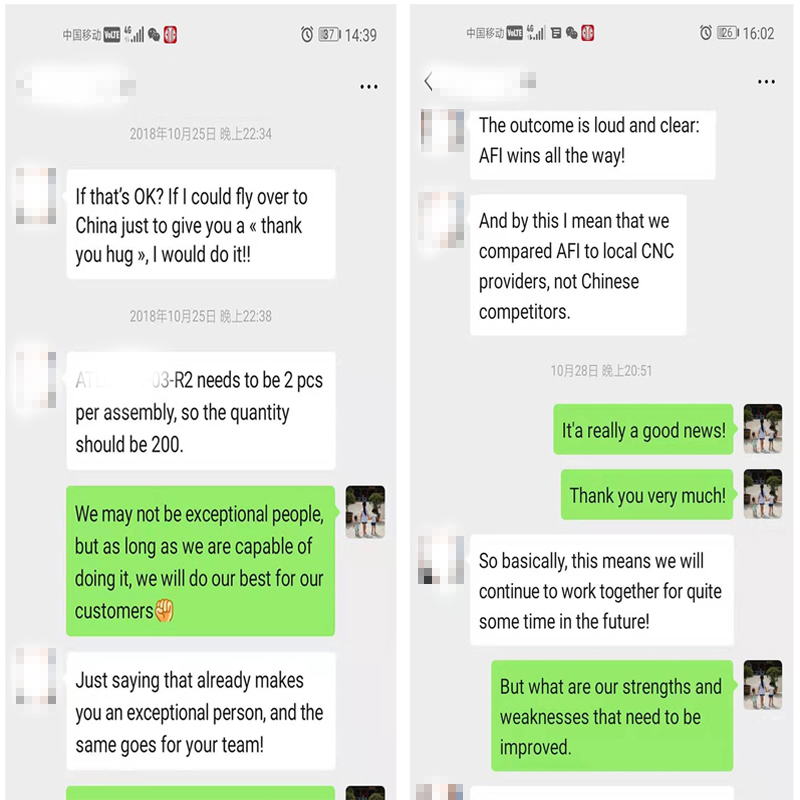

Consistent Feedback From Customers In 30+ Countries Worldwide

” The customer’s newly developed product, has looked for 15 suppliers for technical and price discussion, and finally chose us, when he got the product is very satisfied, he is very happy that he has made the right choice”

“The customer decided to participate in the European exhibition at short notice, we took three days to produce and finish all the products and objects needed for the exhibition.”

“Customers only put forward their own ideas and preliminary drafts, we provide a free design and drawing service within a day, to solve the customer missed or neglected the details of the work”

Knowledge of Machining Manufacturer

Alloy Steel Explained Key Characteristics and Uses

You might ask what is alloy steel. Alloy steel is steel with extra elements like manganese, nickel, or chromium. These … Read More

Why Every Stainless Steel parts Needs Passivation

Every stainless steel part needs passivation treatment to stop rust. If you’re wondering what is passivation of stainless steel, it … Read More

SAVING YOU TIME, MONEY AND TROUBLE

To obtain a qualified supplier, please contact us!